Surface hardening

Surface quenching refers to the heat treatment method of strengthening the surface of parts by using rapid heating after austenitizing the surface without changing the chemical composition and core structure of steel.

Surface heat treatment of the main methods are flame quenching and induction heating heat treatment, commonly used heat sources such as oxygen-acetylene or oxygen propane flame, induction current, laser, and electron beam.

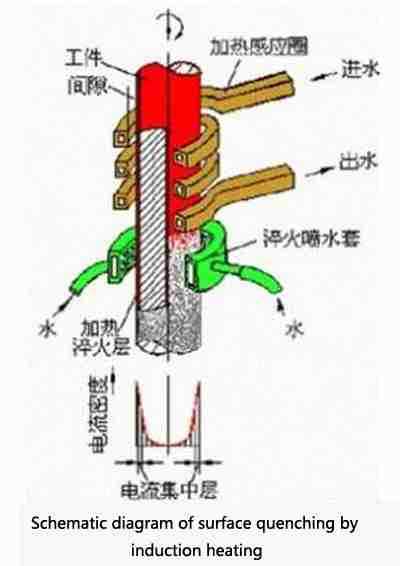

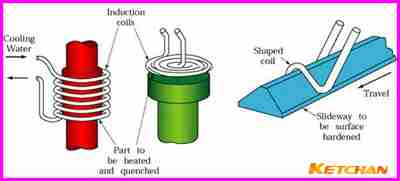

Induction heating

Using alternating current to induce huge eddy current on the workpiece surface, so that the workpiece surface rapidly heating method.

Induction heating is divided into:

1. High-frequency induction heating, frequency 250-300khz, depth of hardened layer 0.5-2mm;

2. Medium frequency induction heating, frequency 2500-8000Hz, hardened layer depth 2-10mm;

3. Power frequency induction heating, frequency 50Hz, hardened layer depth 10-15mm.

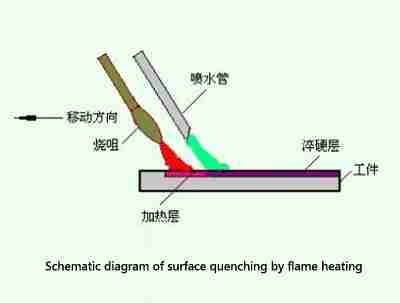

Flame heating

The method of heating workpiece surface directly with acetylene flame. Low cost, but the quality is not easy to control.

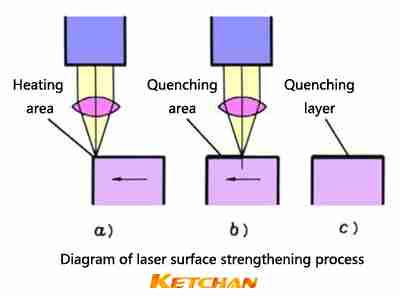

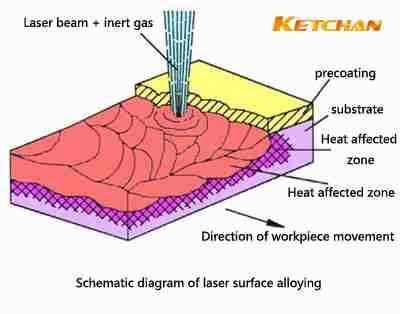

Laser heating

The method of heating workpiece surface with high energy density laser. High efficiency and good quality.

Laser surface strengthening is mainly used for local strengthening parts, such as punching die, crankshaft, cam, camshaft, spline shaft, precision instrument guide rail, HSS cutting tools, gears, and internal combustion engine cylinder liner, etc.