What is Aluminium Pipe Induction brazing machine?

High frequency aluminium pipe induction brazing machine with lightweight, faster heating speed, higher heating efficiency, and energy-saving features, can save 60% more energy than the old electron tube high frequency machine. For simple brazing working situations, can use a standard induction brazing machine. For the complex aluminium, pipes working situation can use our portable induction heater match with 5-20m cables.

Equipped with an air-cooled industrial chiller or built-in industrial chiller to ensure the tube induction heating machines can continue working 24 hours without stopping.

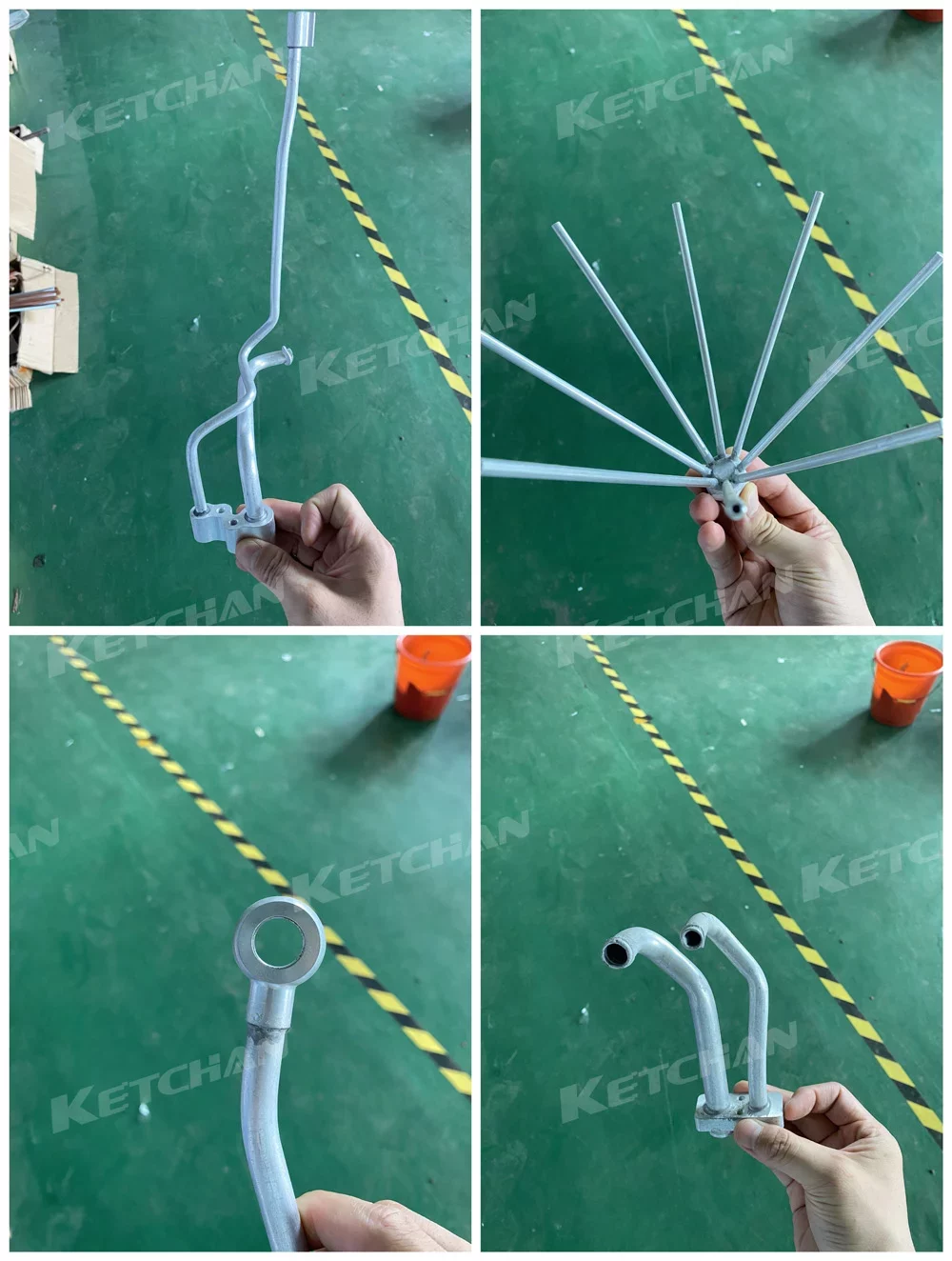

Aluminium tubes induction brazing machine can be used for all kinds of pipes, tubes, joints, fittings, valves, tools, carbides etc, induction brazing welding solutions.

What is Aluminium Pipe Induction brazing machine features?

- Small volume, easy to move, there are standard induction brazing machines and portable aluminum pipe induction brazing machines can be chosen.

- Safety and environmental protection, can effectively improve the working environment, and adapt to the requirements of modern factories;

- Compared with transistor machines, it can save more cost;

- It can cooperate with an automatic mechanism to realize automatic induction brazing welding.

- Easy to learn and operate, can save the labor cost of professional and technical personnel.

What is Aluminium Pipe Induction brazing machine applications?

High frequency aluminum pipe induction brazing machine is mainly by heating the solder material to a certain temperature to melt the solder, so as to connect two kinds of the same material or different materials metals together.

This induction brazing machine is mainly used for induction brazing of metal products, induction welding of aluminum products, welding of various carbide tools, saw blades, steel pipes, copper pipes, copper tubes, brass fittings induction brazing welding of the same and dissimilar metals materials.

How to do aluminium pipe induction brazing process?

When using electromagnetic aluminum pipe induction brazing equipment for the aluminum tubes parts induction welding process, the following points need to be noted.

- Aluminum melting point: Because aluminum and aluminum alloy melting point is relatively low. Therefore, special attention should be paid to the selection of aluminum solder. As a result, the base metal and solder melting points are not much different. So it is very important to control the induction brazing temperature during the heating process.

- Brazing flux choice: When using soft solder for brazing, special attention should be paid to the temperature difference between base metal and solder. Therefore, when selecting aluminum or aluminum alloy for soldering, the solder should be carefully selected according to the tin characteristics.

- Oxidation treatment: Because the surface of aluminum material has a layer of the oxide film. Therefore, when welding aluminum, we need to destroy the oxide film, otherwise, it can not be brazed, but this will lead to the welding parts’ surface oxidation, so when doing induction brazing, it is recommended to choose aluminum pipe induction brazing machine with nitrogen protection.