Summary

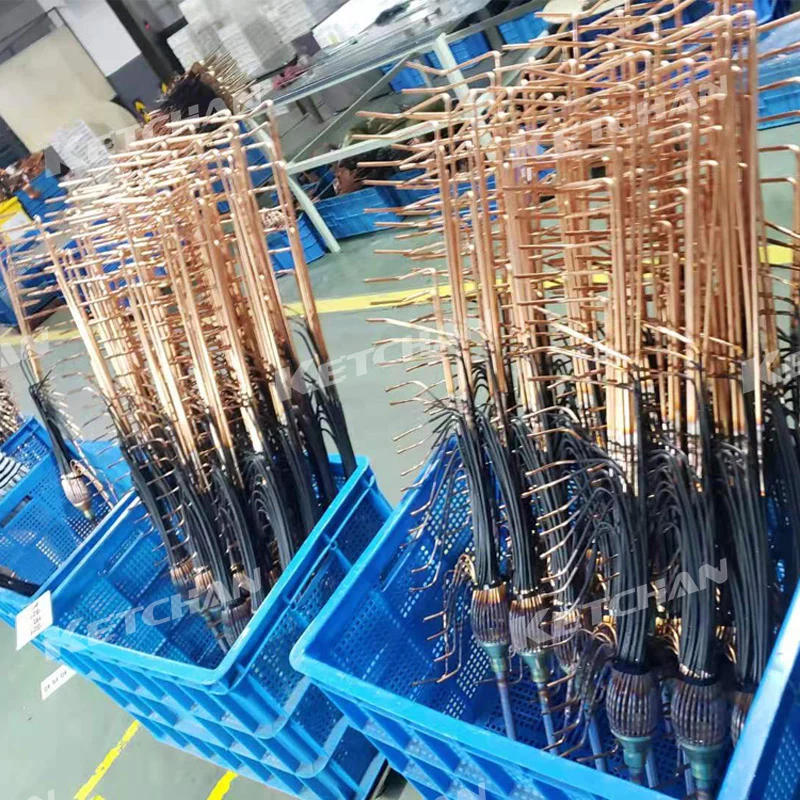

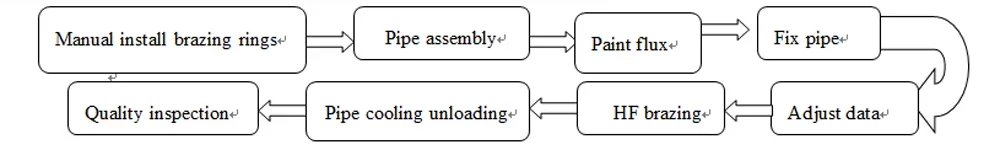

This automated induction brazing system machine adopts digital induction heating mode, to achieve liquid distributor, pipe joint induction brazing welding, and ensure that the welding quality meets the quality requirements, this induction brazing equipment with simple appearance, stable performance, equipment convenient operation, advanced structure features, can achieve rapid replacement fixture, efficient and stable mass production.

Power Supply | 380~480V,±5% |

Power consumption | 10-200KW |

Environment temperature | -10℃~45℃ |

Environment humidity | ≤90% |

Machine color | Color: can be customized |

What is automatic induction brazing system advantages?

- The automatic rotation function is set up in welding tooling. Servo motor is used in rotary power mechanism to ensure concentric shaft rotation. Rotation speed and rotation Angle can be adjusted at will to realize the automatic rotation function in the welding process so that the product is heated evenly.

- High frequency automated induction brazing system reserved processing signal reading interface, facilitate the later information management work.

- High frequency automated induction welding machine stores at least 20 sets of process parameters.

- HF welding machine is equipped with sound and light alarm, red flashing alarm, and sound alarm.

- All process parameters of high-frequency welding machines are set by touch screen, all parameters can be stored and extracted, parameter modification interface needs to set password management.

- Induction heating equipment and workpiece cooling using a separate cooling system.

- The induction heating part of high-frequency welding machine should be heated by at least five sections, and parameters can be set independently.

- The heating coil can be adjusted up and down, and all parameters can be adjusted and stored on the touch screen.

- High frequency welding positioning welding fixture should match the corresponding liquid distributor and pipe joint design, the welding fixture shall ensure that the corresponding distributor and pipe joint are placed and taken without delay, after placement, there will be no visible jitter during high-frequency welding. Brass material or similar material should be used as far as possible to locate the contact part between the tooling and the brass pipe joint of the liquid parting head.

- The equipment must meet party users long-term continuous 24 hours/day production demand. 304 stainless steel is used on the surface of the welding platform, as well as the water sink.

- The working station should be protected by nitrogen, and the nitrogen flow can be adjusted through the flow adjustment switch. The nitrogen inlet shall have measures to prevent cooling water from entering the nitrogen pipe and prevent equipment cooling water from flowing into the nitrogen pipe of the workshop. To prevent the nitrogen filling hole from being blocked by flux or other sundries, it is required that the dirt in the nitrogen filling positioning tool hole should be easy to remove.

- The high-frequency welding machine for the welding tool has the mode of air cooling first and then water cooling. The cooling mode, cooling time point, and time parameter, air cooling, and water cooling flow rate can be adjusted and set. It has automatic and manual modes, does not face the operator in the air-cooled direction. Water cooling should ensure that water does not splash out of the equipment. The water cooling system has filtration devices at the outlet end and the backwater end.

What is automatic induction brazing system applications?

This automated induction brazing system is mainly used for the air conditioning, refrigerator, red wine cabinet, yogurt machine, chiller, refrigeration equipment, central air conditioning, water heater, heat exchanger, etc. copper tube, iron tube, and aluminum tube induction brazing welding solutions.

- Copper tube to tube brazing with casing.

- Induction brazing of condenser capillary.

- Induction brazing of compressor copper tube connectors.

- Transformer, motor rotor stator, generator copper wire copper bar welding, joint copper induction welding;

- Track surface, steel surface quenching, bearing disassembly,smooth shaft induction quenching, etc.

How to choose the suitable automatic induction brazing system?

| Item | Data | Item | Data |

|---|---|---|---|

| Input voltage | 3×460V+1×Zero | Chip speed | 72MHz |

| Frequency | 60Hz | Heating current setting segments | 5 segments (expandable to 32 segments) |

| Rated current | 60A | Setting accuracy of heating time | 0.1S |

| Rated apparent power | (15-40) KVA | Whether process parameters are set to encrypt | Password lock |

| Maximum apparent power | (18-60) KVA | LCD | 3.5-inch true color display, resolution 320×240 |

| Recommended circuit breaker current | 125A | Working current display mode | Machining current curve display |

| Rated output power | (12-35) KW | Alarm interface | Over current, over pressure, under water, under pressure, lack of phase, overheating |

| Maximum output power | (18-45) KW | Communication interface | Db-6 and 2-pin aviation plug |

| Output power range | 8~100% | Bus access | RS485 |

| Control mode | Full digital embedded control software | Output frequency | 20~55KHz |

| DSP | ARM STM32 | Minimum flow of cooling water | 10L/min |

| Maximum cooling water temperature | 40℃ | Ambient temperature | +5℃~+50℃ |

| Cooling water pressure | 4/6 bar | Cooling water quality -PH value | 7.0~9.0 |

Memo:

- The fluctuation range of parameters is as follows: Current fluctuation is less than ±1A, and time fluctuation is ± 0.1s.

- For different users with different induction brazing applications, the automated induction brazing system design and appearance may look different, so please let me know as more as possible about your brazing parts size, material, brazing flux, brazing speed requests details, to make sure that we are clear about each detail, and make the related commercial and suitable automated induction brazing systems technical proposals.