What is ball stud induction hardening machine?

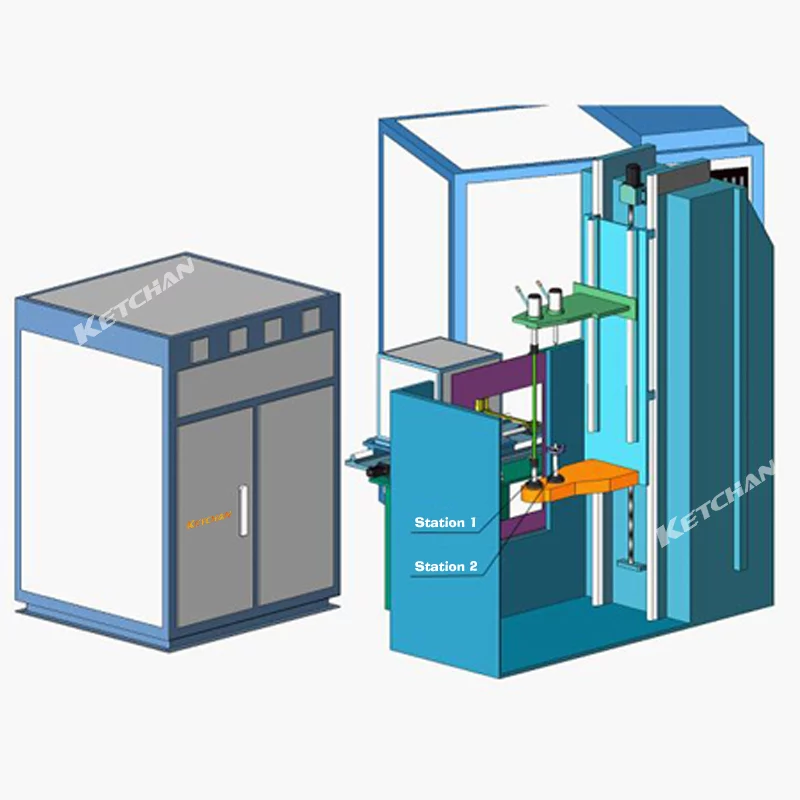

Ball stud induction hardening machine adopts double station/four stations/eight stations vertical structures, induction coil with movement mode do the whole ball pin induction quenching. It is suitable for automobile ball pins, ball studs, ball sockets, etc. mechanical parts surface induction hardening process. Adopt CNC system control and optional special parameter management monitoring and recording system. Realize the quenching workpiece process parameter record and historical data query function. Equipped with digital transistor induction heating power supply and humanized control system. The double-station induction coil mobile CNC quenching machine tool is suitable for the single and batches automobile ball studs and ball sockets parts production, with reasonable structure, complete functions and convenient operation.

How to do ball stud induction hardening process?

Clamp the ball studs on the CNC hardening machine table (fixed by the top and bottom), and press the CNC machine start button, the CNC machine will quickly drop to the ball and the induction coil corresponding position, start the rotation, start the heating delay, the CNC machine according to the set speed does the ball stud and ball sockets induction hardening scanning jobs. When reaching the program sets the quenching temperature, the heating stops, the spraying starts, the rotation delay stops, the spray delay stops, the machine table quickly returns to zero, and the entire ball studs, ball sockets induction quenching process ends.

What is ball stud induction hardening machine features?

- The complete ball stud, ball sockets induction hardening machine mainly consists of an induction heating power supply, CNC induction hardening machine tool, closed-loop water cooling tower, and the induction hardening coils.

- Stainless steel (pneumatic/manual, double/single) spring tip.

- Match multi-ratio induction hardening transformer.

- With imported ball screw.

- The holding length of the workpiece is electrically adjusted.

- Audible/optical fault alarm.

- Use a quick change connector for the waterway.

- Machine tool mechanism: welding frame.

- Rotary control mode: frequency converter/stepper motor/AC servo motor.

- Electronic control system: PLC/ touch screen +PLC/808D/828D/840DSL.

- Transformer slide table adjustment: hand wheel adjustment/automatic adjustment.

- Workpiece/transformer moving motor: gear motor/stepper motor/AC servo motor.

- Workpiece moving or induction coil moving guides: inlaid steel guides/linear guides.

- Working stations: 1 station, 2 stations, 4 stations, and 8 stations can be chosen.

The maximum stroke of the machine(mm) | 600 |

Workpiece maximum swing diameter(mm) | 300 |

Maximum workpiece weight(Kg) | 50 |

Adjusting frame moving speed range (mm/s) | 2~80 |

Adjustment frame movement repeat positioning accuracy (mm) | ≤±0.10 |

Workpiece rotation speed range (r/min) | 20~150 |

What is the ball stud induction hardening machine applications?

This ball stud induction hardening machine is mainly used for automobile ball pins, ball studs, and ball sockets induction heat treatment fields. And also it can be used for other mechanical parts induction heat treating, like all kinds of gears, sprockets, shafts, spline shafts, pins, and other high-frequency quenching treatment.

Why do the ball pin, ball socket induction hardening process?

The ball stud is a key component to ensure the stability of the car’s operation, the smoothness, comfort, and safety of the car, and to make the car drive correctly and accurately. Ball studs require high wear resistance and good plasticity and toughness, so we usually use the ball pin induction hardening machine to induction harden the ball studs.

Its characteristic is that the full quenching surface of the ball head pin is heated electromagnetically at the same time. After reaching the quenching temperature, the inductor will spray water to quench itself. The ball studs can be self-tempered, and the production efficiency is very high.

Zhengzhou KETCHAN ball stud induction hardening machine, the hardening hardness is uniform, and the hardening depth is perfect. Also, the ball pin induction hardening system’s working efficiency is higher and energy-saving a lot, it can save the electricity upto 40%-60%, and save the water upto 60%. 75% reduction in investment in external auxiliary facilities. It is equipped with a unique water cooling system, ensures that the equipment works continuously for 24 hours, helps users to save the cost a lot.

The ball stud induction hardening system induction hardening coil is made to imitate the shape of the workpiece, the making process is complex. To make sure the coil can well match with the induction machines and ensure the heating result is much more uniform.