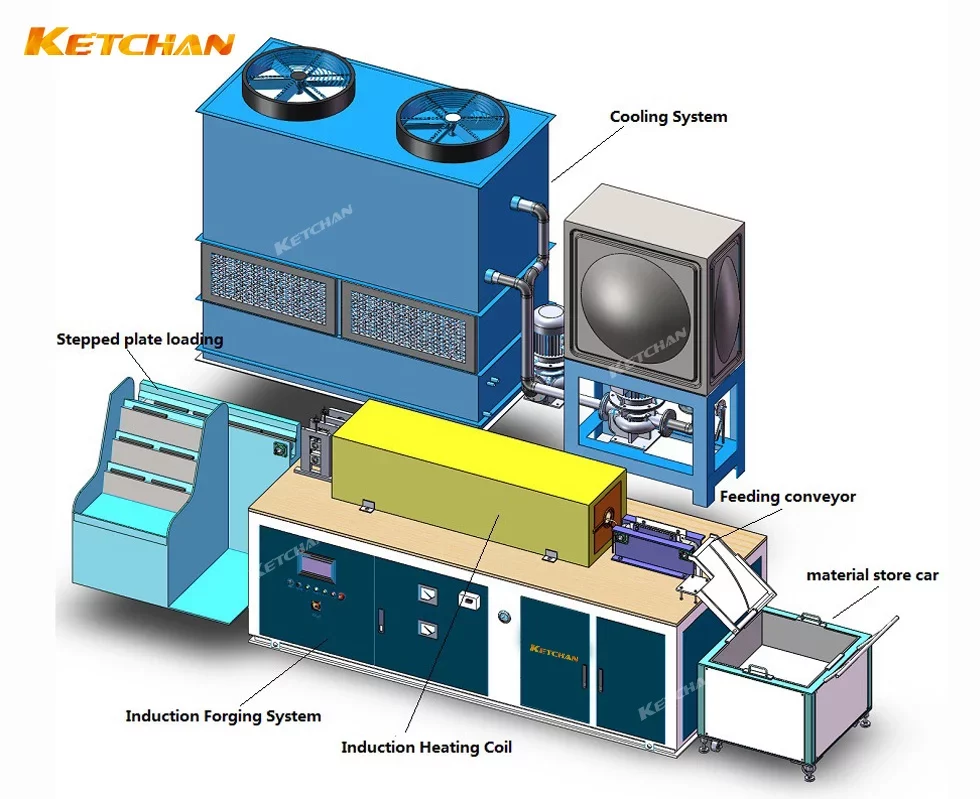

Billet induction forging furnace composition

Billet induction forging furnace is generally composed of intermediate frequency induction forging power supply, electric heating capacitor, induction forging furnace body, feeding and discharging transmission device and temperature measuring equipment etc. When need the automatic control, also including PLC programmable controller, man-machine interface or industrial control computer system and industrial control configuration software and all kinds of sensors.

Billet induction forging furnace applications

We have been in the billet induction forging furnace manufacturer lines for more than 20 years and served thousands of forging factories, and in total, our billet induction forging furnaces are mainly used in the metal materials forging extrusion, hot rolling, shearing before heating, and whole metal materials induction annealing, induction tempering and other induction heat treatment fields.

Billet induction forging furnace technical features

- Fast heating speed, less oxidation, and decarbonization: Due to the billet induction forging furnace principle is with electromagnetic induction, its heat in the workpiece itself. Because this kind of heating method is fast, so little oxidation, high heating efficiency, good process repeatability.

- High automation level: Automatic feeding and automatic discharging sorting device, coupled with our company’s special control software, can realize automatic unmanned operation.

- Uniform heating result, high temperature control precision: By choosing a reasonable working frequency, to adjust the appropriate induction forging depth, in order to achieve uniform heating, small temperature difference core table requirements. The precise control of temperature can be realized by using a temperature control system.

- The replacement of the billet induction forging furnace body is simple and occupies a small area: According to the different sizes of the workpiece, the billet induction forging furnace body of different specifications is configured. Each furnace body is designed with water and electricity quick-change joints so that the furnace body replacement is simple, fast, and convenient.

- Low energy consumption, no pollution: Compared with other heating methods, induction heating has high heating efficiency, low energy consumption, and no pollution. All the indicators are in line with the national standard. Diathermic heating from room temperature to 1250℃ consumes less than 390 degrees per ton.

Billet induction forging furnace technical parameters

Forging model | Heat steel or stainless steel to 1050℃ | Heat copper to 700℃ |

KQZ-35 | 1.25KG/Minute | 1.75KG/Minute |

KQZ-45 | 1.67KG/Minute | 2.33KG/Minute |

KQZ-70 | 2.5KG/Minute | 3.5KG/Minute |

KQZ-90 | 3.33KG/Minute | 4.67KG/Minute |

KQZ-110 | 4.17KG/Minute | 5.83KG/Minute |

KQZ-160 | 5.83KG/Minute | —— |

KQZ-240 | 8.6KG/Minute | —— |

KQZ-300 | 11.25KG/Minute | —— |

KQZ-500 | 17.9KG/Minute | ——– |