What is CNC quenching machine?

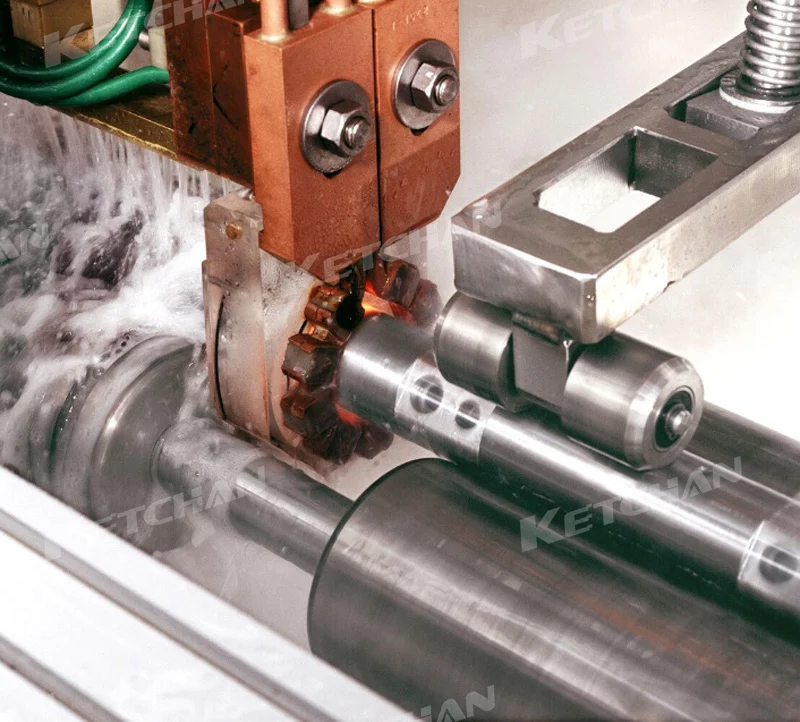

Zhengzhou KETCHAN CNC quenching machines are widely used for all kinds of different metal workpiece surface induction hardening processes. Adopt the fixed machine tool body, the induction coil with continuously scanning hardening method, and the CNC quenching machine tool with servo motor control technology. When the workpiece is fixed on the work table, the machine control system can automatically measure and locate the gap between the inductor and the workpiece according to the set parameters, and automatically heat and cool the hardened workpiece surface. This CNC quenching machine can add electric automatic tracking technology, real-time tracking induction coil, and workpiece clearance, to ensure the hardening result is uniform and reduce the quenching workpiece deformation and machining allowance.

What is CNC quenching machine technical advantages?

- CNC quenching machine is suitable for machine body guide rail and other types of guide rail parts and plate parts induction scanning quenching process.

- Inductor movement is driven by a Siemens servo motor.

- With an induction coil automatic tracking function, set inductor, and workpiece clearance, the system automatically controls each axis to achieve induction coil and workpiece quenching surface constant clearance.

- The precision displacement sensor is from a famous imported brand.

- Inductor and sprinkler adopt water and electricity quick change interface, easy to change and adjust.

- Adopt an automatic control system, all processing parameters of the CNC quenching machine (power, time, quenching fluid flow, quenching speed, quenching fluid temperature, etc.) can be input or displayed through a special parameter screen and can be stored.

- The control system has the functions of monitoring, recording, and printing process parameters.

- Simple production operation, flexible material loading and unloading, high degree of automation, can realize online production;

- Meet the environmental protection requirements, and small pollution, but also reduce the workers’ labor intensity.

What is configuration of CNC quenching machine?

- Machine main body: steel welding/casting.

- Transmission mechanism: precision ball screw/rack and pinion.

- Clearance tracking: Electrical tracking system, the clearance between the induction coil and the hardened surface remains unchanged during induction quenching.

- Induction hardening load: With multi-ratio induction hardening transformer, suitable for all kinds of different workpiece induction hardening jobs.

- Mechanical guide: linear guide.

- Inductor positioning motor: AC servo motor.

- Inductor two-dimensional movement: servo motor drive.

- Quenching mode: standard configuration is inductor movement; Optional workpiece movement mode.

- Protection: water pressure protection, flow protection, air pressure protection, photoelectric safety protection.

- Control box: rotary operation box/control cabinet integrated control box.

- Alarm: sound/light fault alarm, control interface display alarm, and record.

- Inductor and sprinkler cooling interface: stainless steel/brass quick change connector.

- Cooling method: Closed air cooling circulation system/industrial refrigeration unit + internal circulation cooling system.

- Working stations: 1-2 stations can be customized as per technical requests.

What is CNC quenching machine applications?

CNC quenching machine is suitable for single and batch production, widely used in automotive, auto parts, construction machinery, general machinery, machine tool industry surface hardening, annealing, welding, and other induction heat treatment fields. It is mainly used for machining shaft and gear plate parts. The machine tool adopts a precision NUMERICAL control system, and the main drive adopts high precision ball screw, with long life and high precision. The machine has manual, automatic programming functions, and simple operations, easy to master. Mostly the vertical CNC quenching machine tool is mainly used for large shaft, motor, steam turbine spindle, and cylinder piston rod induction hardening processes. The horizontal CNC quenching machine is mainly used for small diameter long shaft, small diameter piston rod, oil cylinder, ball screw, shock absorber piston rod induction quenching.

How to select suitable CNC quenching machine?

Mostly the CNC quenching machine is customized and according to different users, different induction heating applications choose the different CNC quenching machine systems. So when selecting a suitable CNC quenching system, we should consider the following factors.

- We should be clear about the induction hardening parts details, drawings will be better so that we can choose the suitable induction heating machine models. Normally we suggest choosing bigger power induction machines to leave some power balance so that to reach a better induction quenching result.

- Confirm well the induction hardening depth and hardening area, so that to confirm the suitable induction machine frequency range, the higher the hardening depth, the lower frequency should be, the lower the hardening depth, the higher the frequency range should be.

- The heating speed request, the faster the heating speed, the higher the induction heating machine power should be.

In total, we have served thousands of induction heat treatment industries, and have

In our own induction heat treatment center, for simple parts hardening, we have the ready-made CNC quenching machine systems technical proposal for reference. For some complex workpiece induction quenching jobs, we can support doing the induction heat treatment tests in our induction heater center and conclude the suitable induction quenching technical process parameters.