What is Gas Carburizing Furnace?

Gas carburizing furnaces include continuous furnaces, sealed box type furnaces, and pit type resistance furnaces. The production capacity of a continuous furnace can be several times higher than that of other furnace types. Sealed chamber furnaces are used for small batch production. Since the carburizing furnace is filled with flammable gas, it must have strict air tightness.

Pit type of gas carburizing furnace is used for gas carburizing of low carbon steel workpieces and nitriding of alloy steel. The working temperature of the furnace is 950°C. This series of products can realize the automatic control of carburizing when used in conjunction with the carbon potential automatic controller.

What is Gas Carburizing Furnace Structure Features?

Now our company’s products have been upgraded to full-fiber resistance belt heating structure, which has better performance than the original energy-saving brick structure furnace, mainly in the following aspects:

- Less heat storage, the furnace wall is made of refractory fiber, and its heat storage is only about 1/4 of the brick structure furnace, so the heating time of the furnace body is short (1/3 of the brick structure), which is very suitable for frequent shutdown and opening of the furnace. cycle job.

- The heat preservation performance is good, the furnace shell does not feel the temperature rise, and the continuous operation saves 1/6 of the energy compared with the brick structure.

- The heating element has a long service life. Due to the large heat dissipation area of the resistance band, the heat emitted is not accumulated in itself. The temperature of the element itself is low and it is not easy to overheat. The service life is usually more than twice that of the electric furnace wire, which avoids the trouble of electric furnace maintenance.

- The thermal inertia is small, and the downtime for maintenance is very short.

- The temperature control is more precise, the same temperature control system, and the temperature control deviation is smaller.

- It is easy to maintain. If certain fiber cotton is damaged, it can be partially cut with a cutting saw without damaging the whole, and the maintenance is convenient and fast.

What is gas Gas Carburizing Furnace electrical aspects features?

- The temperature control instrument adopts an intelligent program control instrument, the precision is 0.3, and the temperature control deviation can reach ±2℃. The man-machine interface adopts a 7-inch touch screen, which is connected to the smart instrument through a communication protocol, and the instrument operation menu is fully expanded on the touch screen so that the operation is more realistic and convenient. When the instrument parameters are not changed, the touch screen displays the working status of each area of the electric furnace.

- The data recorded by the paperless recorder can be directly checked on it, or it can be copied to the computer through the SD card to realize the recording and printing of the data.

- The temperature control instrument can perform PID and self-tuning adjustments to automatically adapt to the thermal inertia of the heating system. When the furnace temperature is about to reach the set temperature, the instrument automatically reduces the output to prevent the temperature from overshooting.

- The executive element adopts solid state relay power module, which has extremely low working noise (there is a faint sound from its matching axial flow fan), fast switching speed, high switching frequency per unit time, and high-temperature control can be achieved by using it.

- The components have high reliability and long service life.

- Perfect fault protection measures, such as damage to solid state relay components, fan failure, and automatic sound and light alarm.

What is Gas Carburizing Furnace optional part?

Full carbon potential automatic control system

- Achieve precise control of carbon potential.

- Realize synchronous control of temperature and medium dripping.

- When the workpiece material and carburizing requirements are determined, the corresponding program can be directly input to complete the automatic control of temperature rise and medium dripping, avoiding tedious manual operations and greatly improving product quality.

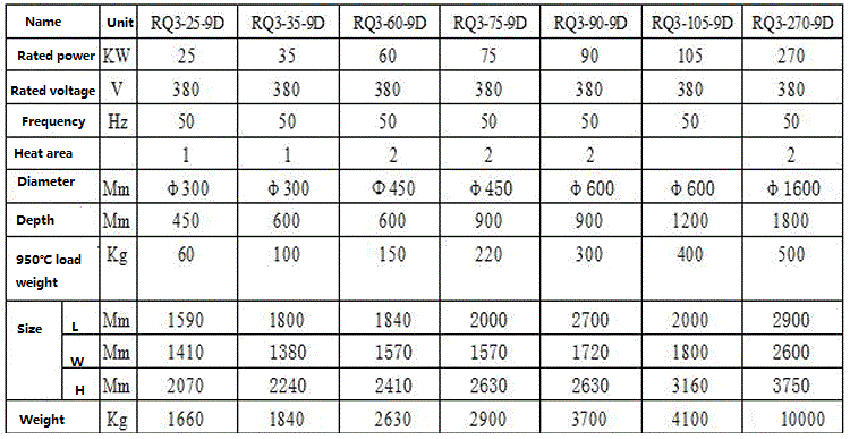

How to choose suitable Gas Carburizing Furnace?