What is gas nitriding furnace?

Pit gas nitriding furnace is a high energy-saving periodic operation type nitriding furnace. It is mainly used for gas nitriding heat treatment of various steel mechanical parts, automobile curved glaze, motorcycle brake pads, molds, etc.

Pit gas nitriding furnace is composed of a furnace shell, furnace lining, furnace cover lifting mechanism, furnace sealing fan, muffle tank, heating element, and electric control system. It is an energy-saving composite structure built with ultra-light energy-saving refractory bricks, aluminum silicate fibers, diatomite insulation bricks and asbestos boards.

This well-type gas nitriding furnace adopts energy-saving furnace lining, double water-cooled furnace tank cover, vacuum rubber seal, and upper and lower two-zone or multi-zone temperature control. The nitriding furnace heat preservation, furnace temperature uniformity, sealing performance, and nitriding speed have been greatly improved, and the furnace type is consistent with international standards. The shell of this series of well-type gas nitriding furnaces is welded by steel plates and section steels, the furnace lining is made of ultra-light, high-strength energy-saving refractory bricks, and the outer layer of the furnace lining is sandwiched with aluminum silicate fibers, and filled with expanded thermal insulation powder. The heating element is spirally wound by high-temperature resistance wire, installed on the bricks of the furnace lining, and a stainless steel vacuum tank is installed in the furnace. A double-ended stainless steel dripper is installed on the furnace cover for dripping methanol so that the temperature and atmosphere in the nitriding furnace are uniforms. The furnace cover is equipped with a sampling pipe, an exhaust pipe, and an input pipe on the upper part of the furnace tank side wall for ammonia gas input. The furnace tank and furnace cover are sealed with water-cooled vacuum rubber and are equipped with compression bolts. The exhaust gas in the gas nitriding furnace is discharged out of the furnace through an exhaust pipe.

What is gas nitriding furnace technical advantages?

The RN series pit type gas nitriding furnace is made of steel plate into a cylindrical shell, and inside is a heating working chamber made of standard refractory bricks. The insulation material is filled between the heating chamber and the shell. There is a stainless steel welded sealed furnace tank in the heating chamber, the upper part of the furnace tank is equipped with a vacuum rubber sealing ring, the lower part is a water cooling jacket, and the top of the furnace cover is equipped with a soaking fan to ensure the uniform atmosphere in the furnace.

- The new energy-saving furnace lining is adopted, which has fast heating, less heat loss, and good furnace temperature uniformity, which is suitable for nitriding treatment of various types of parts;

- The microcomputer intelligent instrument can be used, the furnace temperature can be set according to the technical requirements, the automatic tracking display can be realized, and the PLC program control can be realized;

- A variety of temperature gas nitrogen control upper and lower microcomputer networking, coupled with the manipulator can achieve automatic control of the whole process.

- The pit-type nitriding furnace is equipped with a furnace inside the nitriding tank with no pollution to the workpiece.

- The pit-type nitriding furnace can be configured with a variety of specifications according to user needs and can be designed and manufactured in non-standard.

What is gas nitriding furnace applications?

It is used to improve the surface hardness, wear resistance, and corrosion resistance of workpieces. Suitable for chemical heat treatment of crankshafts, cylinder barrels, piston rings, gears, screw rods, molds, frying pans, and other workpieces that need to increase wear resistance and corrosion resistance. Nitrided parts are greatly improved in fatigue resistance, corrosion resistance, etc. After nitriding treatment of high-speed steel tools, the service life can be increased by 20-100%; After the extrusion die is nitrided, the service life can be increased by 3-5 times. The nitrided surface layer is hard but not brittle and has a certain toughness, which is not easy to peel off.

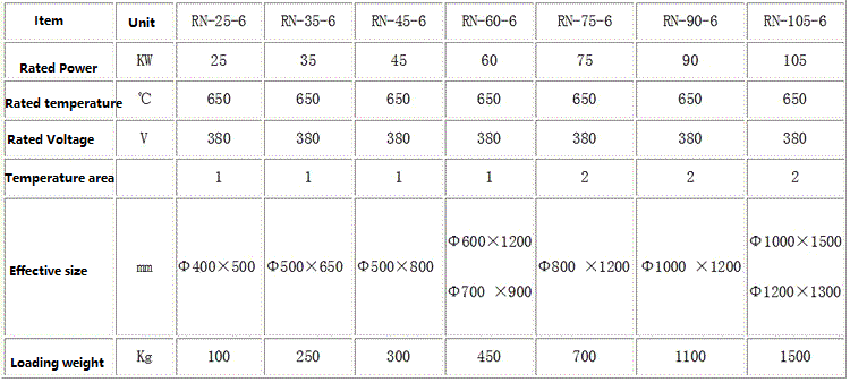

How to choose the suitable gas nitrding furnace?

If the above datasheet has no suitable one for your applications. Please contact us and we can customize the gas nitriding furnace as per your requests.