What’s high frequency heating machine?

The principle of high frequency heating machine: it is to use the large current flow of the high frequency wave to be wound into a circular state or the shape of the induction heating coil, high frequency induction is usually made of hollow copper tube.

A high-frequency heating machine is a powerful magnetic beam with instantaneous polarity change produced by the high frequency induction coil. The metal that needs heat treatment is placed in the high-frequency coil, and the magnetic beam will run through the whole heated metal object. In the induction heating object inside and in the opposite direction of the induction heating current, produce the corresponding strong eddy current. Because there is resistance in the metal of induction heating, it produces strong joule heat energy, so that the temperature of the workpiece of induction heating rises rapidly, so as to achieve the purpose of induction heat treatment.

Therefore, high frequency induction heating machines in the industry can also be called: high frequency induction heating equipment; High and medium frequency induction quenching equipment; Induction forging equipment; High frequency quenching machines, high frequency induction hardening machines, high frequency induction brazing welding machines.

What’s high frequency heating machine applications?

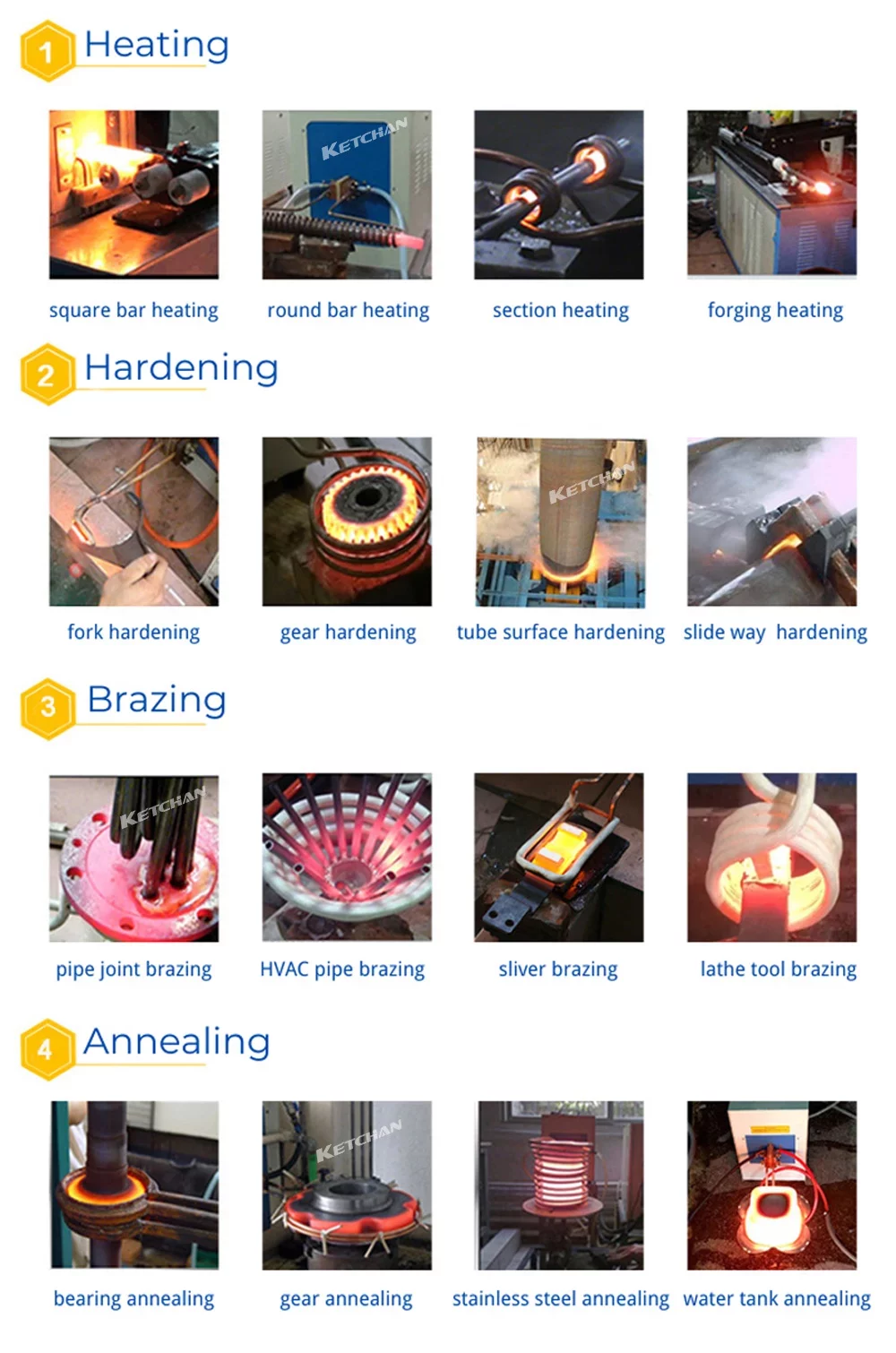

High frequency heating machine is mainly used for industries: High frequency induction welding, high frequency induction heat treatment, high frequency induction metal melting, etc. Like carbide saw blades, diamond cutting tools, drilling tools, turning tools, planers, milling cutters, reamers,s, and other cutting tools induction welding. Induction heat treatment of standard parts, bolts, power tools, hardware tools, hand tools; Pliers, wrench, screwdriver, hammer, ax, auto parts, crankshaft, connecting rod, piston pin, crank pin, sprocket, camshaft, valve, all kinds of rocker’s arm, rocker arm shaft; High frequency induction quenching treatment for all kinds of gears, spline shafts, half shafts, small shafts and forks in the gearbox.

high frequency heating machine applications

How to install the high frequency heating machine?

- Connect power: This high frequency heating machine is a three-phase power supply mode (380V), connecting three red wires to special three-phase switch or air switch (above 65A) respectively. Connect the ground wire again.

- Connect water: High frequency heating machine uses the cooling water pressure is 0.1Mpa-0.3mpa (about 1-3 kg). Can choose water pump, water tank, cooling tower, and industrial chiller. The water pipe is used to connect the water outlet of the pump with the water inlet of the machine, and the water outlet of the machine is used to return the water back to the pool to achieve water circulation cooling.

- Install induction coil: select, install and fix the induction coil according to the shape and size of the heated metal workpiece. Note that the induction coil should not have a short circuit phenomenon.

- Put into the workpiece: the workpiece that needs to be heated into the center of the high frequency heating machine heating coil, the workpiece, and the induction coil should not touch.

Why use high frequency heating machine?

- High frequency heating machine adopts IGBT module, energy saving: 30% than the electronic tube type, 20% than the SCR medium frequency induction heater.

- Fast heating speed: the fastest heating speed is less than 1 second, and the heating speed can be adjusted, and the heating temperature can be well controlled;

- Wide application: can heat any metal workpiece (according to the shape of the workpiece to make different induction heating coils);

- High efficiency: the high frequency heating machine has automatic settings and various protection functions, and the operation can be completed by one person, thus reducing the process and improving the production efficiency.

- Good effect: the workpiece surface heating evenly, heating up fast, reduce the workpiece surface oxidation layer and workpiece deformation degree;

- Small footprint: the equipment is small in size, light in weight, occupies less space, easy to move.

- Easy to operate: CNC design, the whole machine without debugging, installation and operation is very simple, 5 minutes can learn;

- Good environmental protection: no noise, pollution, and open fire, easy to meet the requirements of environmental protection and fire protection.

How to maintain high frequency heating machine?

When used in places with a poor air environment, dust should be prevented from entering the high-frequency heating machine, and water should not splash into the machine. To keep the cooling water clean, regular replacement. Air circulation should be maintained in high temperature environment.