What is high frequency induction bending machine structure?

The complete high frequency induction bending machine system includes two following parts,they are

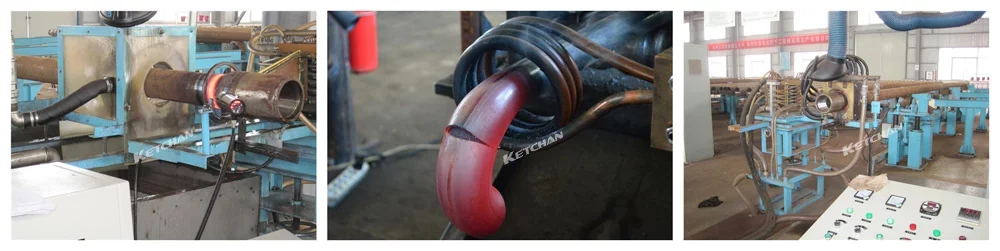

- One is high frequency induction bending machine for steel pipes ring induction heating, make the steel pipe heating up rapidly to the required temperature (usually 800-1000 ℃). The quality of the medium frequency induction heating system determines the extent of pipe bending machine energy saving.

- One is the hydraulic mechanical drive system ,mainly used in steel pipe clamp, push, to coordinate the movement of each system. Under the medium frequency induction ring heating condition to do the steel pipe bending.

Internal Details of High Frequency Induction Bending Machine

High frequency induction bending machine technical data

Project | Unit | Hot-pushing pipe-bending |

Minimal processing round pipe bend pipe diameter | mm | φ219 |

Maximum processing round pipe bend pipe diameter | mm | φ762 |

Processing round pipe bending pipe wall thickness | mm | 6~30 |

Pipe bending radius | R(Bending Radius) | R=2M~20M |

Pipe bending Angle | 0 | 120 |

Biggest processing square tube bent pipe diameter | mm | 400*400 |

Minimum processing square tube bending tube diameter | mm | 300*300 |

Processing pipe wall thickness | mm | 6~30 |

Square tube bend radius | R(Bending Radius) | R=2M~20M |

Machine working system pressure | Mpa | 21 |

Equipment forward thrust | T | 200 |

Main cylinder effective stroke | mm | 12000 |

Pipe bending speed adjusting range | mm/s | 0.25~3 |

Square tube bending speed adjusting range | mm/s | 0.25~3 |

Hydraulic equipment power | KW | 37 |

Main body capacity | KW | 37 |

Machine outline | M | 28*2.2*1.6 |

Machine total weight | T | 28 |

High Frequency Induction Bending Machine applications

How to choose the suitable induction heating machine?

Induction heating machines have very wide application ranges during the heat treatment production period. When choosing suitable induction heating machines, should consider the following technical data and requests.

- The heated parts overall size and shape: Large workpiece, bar material, solid material, should be selected bigger power, low frequency induction heating equipment; If the workpiece is small, pipe, plate, gear, etc., the induction heating equipment, lower power and high frequency induction bending machine should be selected.

- The metal parts heating depth and area: If require high heating depth, a bigger heating area should choose bigger power, lower frequency induction heating machine. If require less heating depth, smaller heating area, or local heating, should choose smaller power, high frequency induction heating machine.

- Heating speed requests: Faster heating speed, should choose bigger power, high frequency induction heating machine.

- Continuous working time requests: If request a long time working time, should choose bigger power induction heating machines.

- Heating process requests: For different heating processes, combined with different heating requests, can consult our engineers to suggest suitable induction heating systems for your choice.