What are high frequency induction soldering machine advantages?

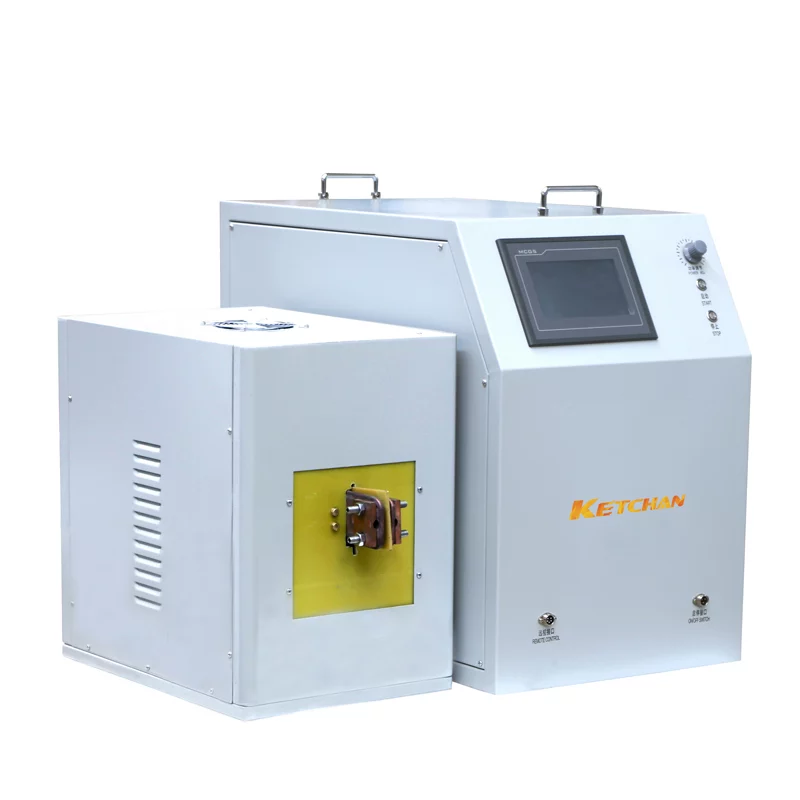

Our high frequency induction soldering machine power from 10KW-300KW with a frequency range of 0.1-40KHZ with widely induction heating applications.

- Power saving: full digital frequency tracking technology makes IGBT always work in zero open states, and the inverter power factor is always kept above 95%. The composite motherboard structure makes the whole inverter unit without an absorption loop, and the inverter power is greatly improved.

- High control precision: high design marking rate, control marking rate up to 0.025%.

- Fast control precision: control response speed is nanosecond level, that is 0.000000006 seconds.

- Good stability, high complex accuracy: no power drift phenomenon occurs during cumulative startup.

- Good anti-interference performance: the change in temperature, humidity, and power grid voltage will not affect the equipment.

- Low cost: the use of uncontrolled rectifier, inverter power regulation, and simple topology, to meet the conventional heating conditions, achieve the minimization of the device, simple structure characteristics, and effectively control the cost of the machine.

What are high frequency induction soldering machine applications?

ZHENGZHOU KETCHAN’s high frequency induction soldering machine,because of its DSP digital control and fast heating speed features, it is widely used in the metal parts induction brazing, induction forging, induction hardening, induction annealing, melting etc.

- Induction braze welding: Induction brazing of carbide turning tool, drill bit, composite geological bit, etc.

- Induction forging: Induction hot forging of bolts, nuts and other round steel.

- Induction quenching and tempering: quenching gears, shafts, and other mechanical parts.

- Induction heat treatment: Induction heat treatment of hardware tools, such as a wrench, pliers, screwdrivers, etc.

- Induction hardening: Machine guide rail, dovetail groove, bed surface, and another induction hardening.

- Induction annealing: Wire, steel wire, galvanized wire, stainless steel wire, steel bar, copper wire and so on.

- Induction tempering: Train track, train guide rail, and other induction tempering treatments.

- Hot induction melting: roller table, middle groove, piston rod, oil rod and other surface spray metal powder induction remelting process.

- Hot shrink fitting: roll sleeve, coupling, gear shaft, bearing, wheel, and other interference induction heat matching applications.

- Liquid induction heating: water, oil, liquid medicine, and other liquid induction heating applications.

- Induction preheating: Induction preheating process for oil pipeline, steel plate and large iron pipe.

- Steel rolling: Diathermy application of scrap steel bar, scrap material, and ship plate before rolling.

Melting: Steel, aluminum, scrap metal, and other induction heating and melting applications.

How to select a suitable high frequency induction soldering machine?

When doing different parts induction brazing solutions, it is very important to choose the suitable high frequency induction soldering machine power and frequency ranges.

Power choice: According to detailed braze parts shape, size, material, and brazing flux choose the suitable induction soldering machine power level.

Frequency choice: The larger the induction welding area, the lower the frequency range should be. The tools size less than 30*30*30, can choose high frequency induction soldering machine, the tools size more than 30*30*30, can choose a medium frequency induction soldering machine. The choice principle is: The larger the workpiece diameter, the lower the frequency induction heater should be.

What kinds of services ZHENGZHOU KETCHAN can provide?

24 hours fast response: We provide 24 hours online customer service.

Professional service team:

- Our 7*24 hours online service people, you can let us know your technical requests and suggest suitable high frequency induction soldering machine models.

- Managers: Make suitable technical suggestions, and fast and accurate technical quotations.

- R&D engineers: As per different users’ technical requests, we communicate with users to make the final induction machine technical proposal.

- Process Testing engineers: We can do some induction heating process tests for you until you are satisfied with the heating requests.

- FAE engineer: technical support, training, and after-sales service.

Warranty period: 12 months.

Delivery time: For a standard high frequency induction soldering machine, delivery time is in 48 hours after getting your payment.