The pin shaft is a kind of fastener, which will be affected by external forces during use, and the wear will be serious. It is necessary to enhance the strength, hardness, wear resistance and fatigue resistance of the pin shaft surface. Pin shaft high-frequency hardening equipment is specially used to complete the quenching heat treatment of shaft workpieces such as pin shafts.

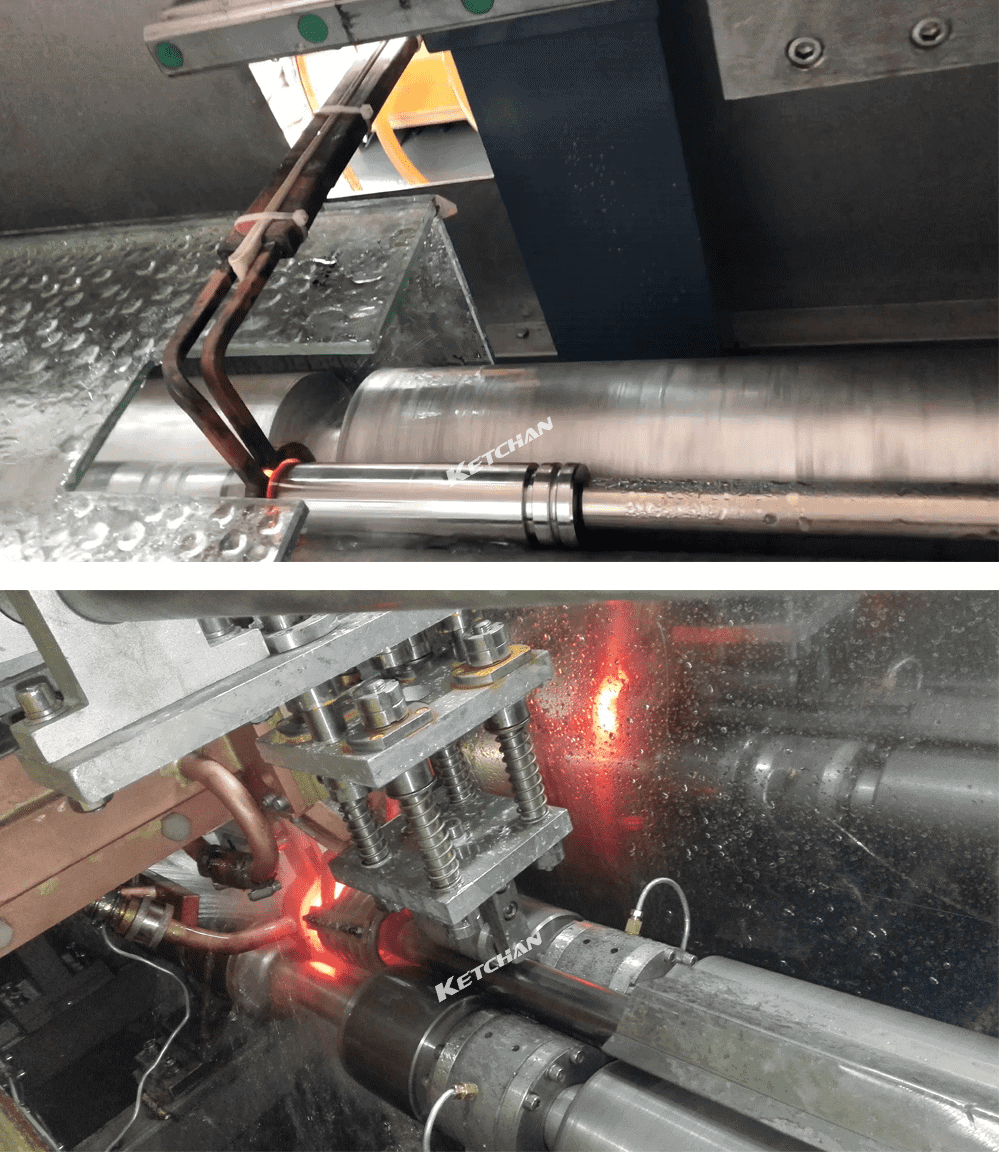

It is composed of high-frequency induction heating power supply, quenching machine tool and cooling system. The induction coil adopts a profiling induction coil, which scans and quenches while spraying water.

Using IGBT as the main device, full-bridge inverter, perfect protection function, high reliability, automatic frequency tracking and multi-channel closed-loop control, simple installation and convenient operation;

It can be remotely controlled and equipped with infrared temperature measurement to realize automatic temperature control, improve heating quality and simplify worker operations.

The complete indution hardening equipment adopts a profile structure body, which is low in cost, light in weight, economical and practical, high in automation, high in production efficiency, and low in operating costs. The driving motor for workpiece operation only needs 250W, and the power consumption of the whole machine is less than one-fifth of that of mechanical equipment.

The selection of high-frequency hardening quenching heat treating equipment for shaft quenching is as follows:

- Generally, for shafts ≤Φ20, 50KW high-frequency hardening quenching equipment is selected.

- For shafts >Φ20 and <Φ40, use 80KW high-frequency quenching equipment.

- Generally, shafts >Φ40 and <Φ80 can use 120KW high-frequency quenching equipment.

- =Φ80 shaft technology requires low speed and small quantity, and 120KW high-frequency quenching equipment can also be used.

- =Φ80 shaft technology requires fast speed and large quantity, generally choose 160KW high-frequency quenching equipment.

- Generally, shafts >Φ80 and <Φ120 can use 160KW high-frequency quenching equipment.

Tags:for Sale, high frequency hardening machine, high frequency heat treating machine, horizontal shaft hardening machine, Induction hardening process, induction hardening system, induction heat treating system, induction heater, induction heating, induction heating machine, KETCHAN, KETCHAN Electronic, manufacturer, Manufacturers, pins hardening system, price, shaft hardening system, shaft induction hardening machine, shaft induction quenching machine, supplier, Suppliers, vertical shaft hardening machine, Zhengzhou KETCHAN, Zhengzhou KETCHAN Electronic