What is IGBT induction melting furnace?

IGBT intermediate frequency IGBT induction melting furnace is a series resonant medium frequency induction melting furnace, its inverter component is a new type of IGBT module (insulated gate bipolar transistor, Germany production), it is mainly used for melting ordinary carbon steel, alloy steel, cast steel, non-ferrous metals. It has the advantages of fast melting speed, energy saving, and low harmonic pollution.

What is IGBT induction melting furnace advantages?

ZHENGZHOU KETCHAN specializes in the production of small-medium frequency IGBT induction melting furnaces, medium frequency melting furnaces, intermediate frequency electric furnaces, medium frequency induction melting furnaces, melting furnaces, molten silver gold furnaces, melting copper furnaces, molten aluminum furnaces, cupola, molten steel furnace, molten silicon furnace, the furnace molten lead, nickel alloy furnace, small experimental furnace, high-frequency furnace, the power supply is using IGBT power imports components, more integration, miniaturization, The effective output power reaches more than 90%, saving energy, saving 40% energy than the traditional SCR medium frequency! Melting time 30-40 minutes per furnace!

- Product startup performance is very good: IGBT induction melting furnace adopts series resonant circuit to completely solve the problem of SCR if starting difficulty.

- The IGBT induction melting furnace produces almost no high harmonics: It will not pollute the power grid, transformers, switches do not heat, and will not interfere with the operation of electronic equipment in the factory.

- The product has high reliability: The main components are all the components produced by the world-famous factory, IGBT transistor is produced by Siemens in Germany.

- High energy-saving functions, the IGBT induction melting furnace water circulation system adopts a water heat exchanger and internal and external water circulation system. The internal circulation is distilled water, in long-term use, the water in the equipment does not scale and does not block, greatly reducing the fault, and save maintenance costs.

- The product can always maintain constant power output in the induction smelting process. Thyristor medium frequency power supply by regulating the power, and energy-saving IGBT transistor intermediate frequency power supply using frequency and power, it is not affected by how much burden and lining thickness, keep constant power output in the whole smelting process, especially for the production of stainless steel, copper, aluminum, etc when not in permeable material, more show its superiority, fast melting speed, burning less burden element, reduce the casting cost.

IGBT induction melting furnace applications

How to choose IGBT induction melting furnace crucible material?

IGBT induction melting furnace according to different melting metal and different melting volume requests matching different types of crucible size and materials. Gold, silver, copper, and aluminum are normally matching graphite crucible, iron, stainless steel is matching magnesium oxide crucible, and melting furnace power consumption is 280-340 units of electricity per ton. Please select the suitable IGBT induction melting furnace according to your own metal melting parameters.

- Crucible of high purity graphite clay: the crucible of pure graphite is used. The temperature is up to 2600 degrees. It is suitable for 1-6kg of gold, silver, platinum, and other small-volume metal induction melting jobs.

- Graphite clay crucible: suitable for gold, silver, copper, aluminum, tin, lead, and other small metal induction smelting, smelting capacity of 3-300kg.

- Magnesium oxide, corundum, zircon crucible: suitable for iron, platinum, steel, and other metals smelting capacity of 3-100kg.

- Badun graphite clay crucible: new medium frequency IGBT induction melting furnace is used for gold, silver, copper, aluminum, tin, lead, and other metals induction smelting, the smelting capacity is 3-2000kg

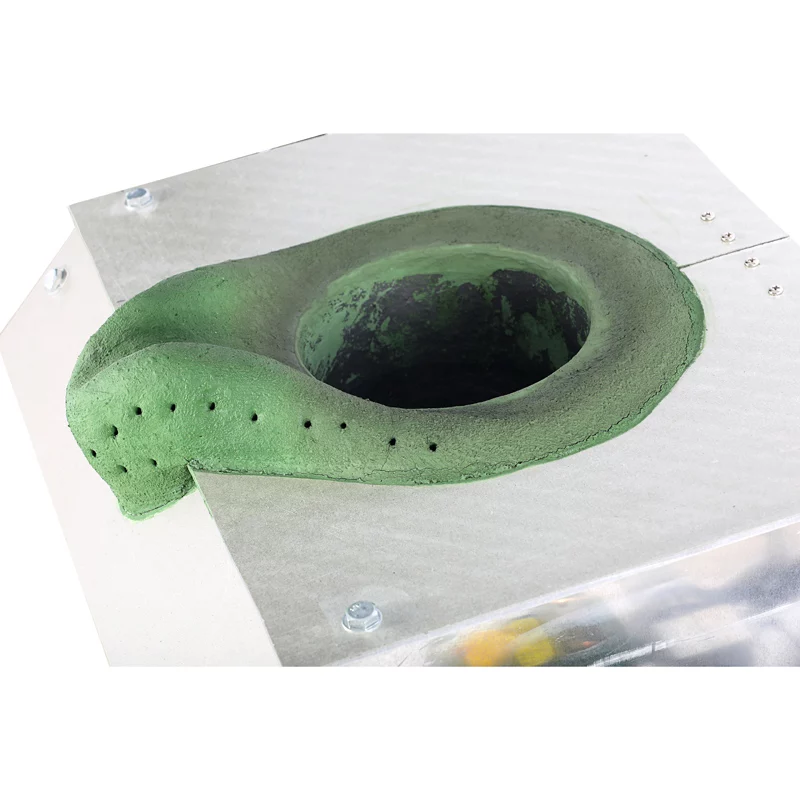

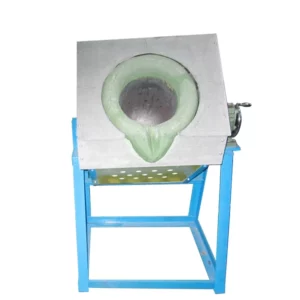

KETCHAN's Durable Crucible

How to choose a suitable IGBT induction melting furnace?

| Model | Melting Steel/Iron | Melting Aluminum/ Aluminium alloy | Melting Copper/Gold/Silver/ Precious Metal |

|---|---|---|---|

| KQZ-15KW | 3KG | 3KG | 3KG、5KG、10KG |

| KQZ-25KW | 5KG | 5KG | 20KG |

| KQZ-35KW | 10KG | 10KG | 30KG |

| KQZ-45KW | 18KG | 18KG | 50KG |

| KQZ-70KW | 25KG | 25KG | 100KG |

| KQZ-90KW | 40KG | 40KG | 120KG |

| KQZ-110KW | 50KG | 50KG | 150KG |

| KQZ-160KW | 100KG | 100KG | 250KG |

| KQZ-200KW | 150KG | 150KG | 350KG |

| KQZ-300KW | 200KG | 200KG | 500KG |

| KQZ-500KW | 250KG | 250KG | 600KG |

Memo: We support customizing all kinds of different IGBT induction melting furnaces for different sizes and material metal melting jobs.