What is induction annealing machine?

The induction annealing machine is referring to the cold deformed metal heated below the recrystallization temperature to remove the internal stress by the induction heating equipment. But in this process, the cooling hardening effect of the heat treatment will be retained. In the machinery manufacturing industry, induction annealing is generally used as a preparatory heat treatment process in the workpiece manufacturing process.

What are the methods of induction annealing?

- Full induction annealing: Used to refine the medium and low carbon steel after casting, forging, and welding mechanical properties of poor coarse superheated organization, heating the workpiece to all ferritic transformation into austenite temperature above 30~50℃, heat preservation for a period of time, and then slowly cooling with the induction heating furnace, in the cooling process of austenitic steel organization becomes fine.

- Spheroidizing annealing: Used to reduce the high hardness of tool steel and bearing steel after induction forging. The workpiece is heated to 20~40℃ above the temperature at which the steel begins to form austenite, and cooled slowly after insulation. In the cooling process, the lamellar cementite in the pearlite becomes spherical, thus reducing the hardness.

- Isothermal annealing: It is used to reduce the high hardness of some alloy structural steels with high nickel and chromium content for cutting. Generally cooled to the most unstable austenite temperature at a faster speed first, heat preservation appropriate time, austenite into torstenite or soxaustenite, hardness can be reduced.

- Recrystallization annealing. It is used to eliminate the hardening phenomenon (hardness increase, plasticity decrease) of metal wire and thin plates in the cold drawing and cold rolling process. The heating temperature is generally 50~150C below the temperature at which steel begins to form austenite. Only in this way can the work hardening effect be eliminated to soften the metal.

- Graphitization annealing: It is used to change cast iron containing a large amount of cementite into malleable iron with good plasticity. The process operation is to heat the casting to about 950℃, and cool it properly after a certain period of heat preservation so that the cementite can decompose into flocc graphite.

- Diffusion annealing: It is used to homogenize the chemical composition of alloy castings and improve their performance. The method is to heat the casting to the highest temperature possible on the premise of no melting, and hold it for a long time. After the diffusion of various elements in the alloy tends to be evenly distributed, the casting is cooled slowly.

- Stress relief induction annealing: It is used to relieve internal stress of iron and steel castings and welds. For steel products heating after the formation of austenite temperature below 100~200℃, cooling in the air after insulation can eliminate internal stress.

Why use induction annealing machine?

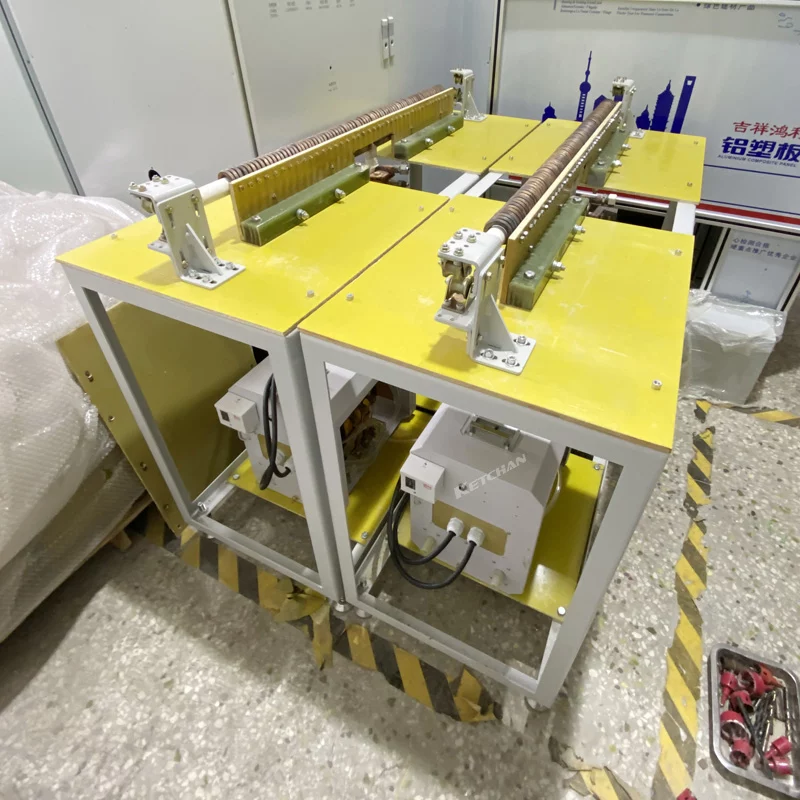

- ZHENGZHOU KETCHAN induction annealing machine adopts MOSFET, IGBT power devices, and frequency conversion control technology, high efficiency, energy saving, and larger output power;

- With constant current and constant power control function, greatly optimizing the metal heating process, to achieve efficient and rapid heating, product superiority has been greatly improved.

- With 100% load design, can work continuously for 24 hours, can be equipped with infrared temperature measurement to achieve automatic temperature control, improve heating quality, and simplify manual operation;

- With the setting function of three periods of heating, insulation, and cooling, the required heating and insulation process can be obtained, and it is suitable for the mass and repetitive heating place;

- With over current, over pressure, lack of water, lack of phase, load discomfort, and other states display, to provide higher reliability and durability.

What is induction annealing machine application?

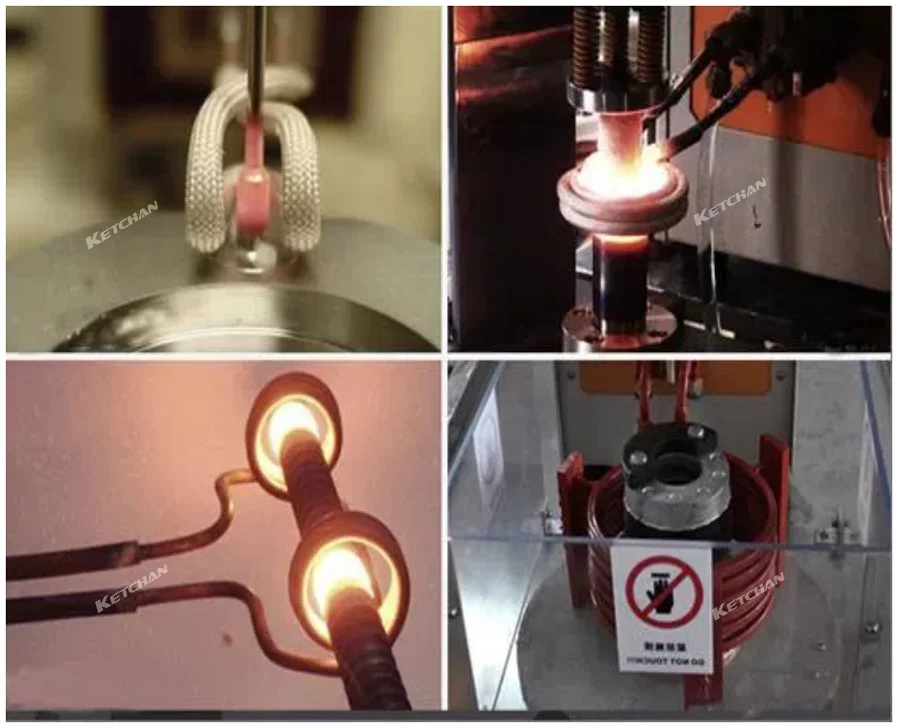

The induction annealing machine is mainly composed of an induction coil, an induction heating power supply, it is through the use of the electromagnetic induction principle to achieve the induction annealing purpose.

- Stainless steel industry: stainless steel basin, stainless steel pot, stainless steel tableware, stainless steel tube, stainless steel cup, a tank of annealing, annealing edge stretching.

- Metal workpiece industry: golf ball head, cue, copper lock head, hardware copper accessories, kitchen knife handle, blade, aluminum pot, aluminum bucket, aluminum radiator, and all kinds of aluminum products induction annealing process.

- The induction annealing of the plate, pipe, wire, and other industries, reduces the steel hardness, and is conducive to forging, and stretching, such as stainless steel pot, stainless steel plate, bar, and steel pipe and wire.