Summary

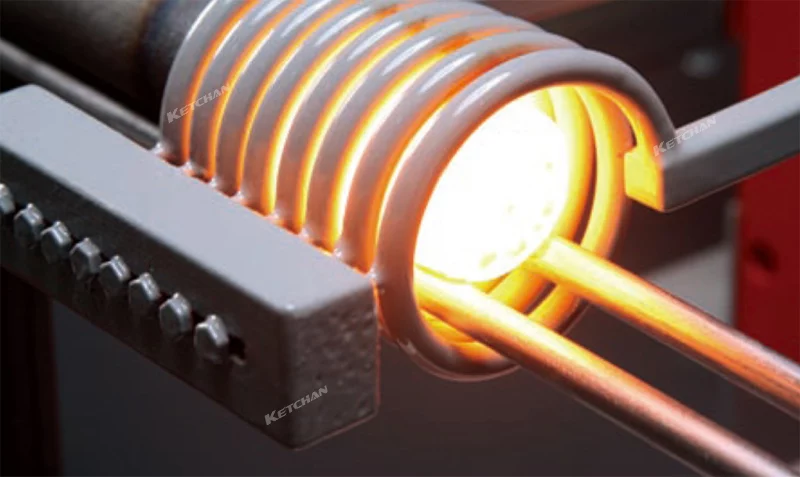

Medium frequency induction billet heating furnace belongs to induction heating equipment, which uses electromagnetic induction heating principle to heat metal forging, hardening and tempering, and hot stamping, especially for precision forging medium frequency induction billet heating furnace has very significant characteristics and heating advantages.

Induction billet heating furnace technical parameters

| Models | Max.Input Power | Common material heating capacity | |

|---|---|---|---|

| Heat steel, stainless steel to 1100 ℃ | Heat Brass to 700℃ | ||

| KQDZ-35 | 35KW | 1.4Kg/Minute | 2Kg/Minute |

| KQDZ-45 | 45KW | 1.8Kg/Minute | 2.55Kg/Minute |

| KQDZ-70 | 70KW | 2.85Kg/Minute | 4Kg/Minute |

| KQDZ-90 | 90KW | 3.64Kg/Minute | 5.1Kg/Minute |

| KQDZ-110 | 110KW | 4.5Kg/Minute | 6.5Kg/Minute |

| KQDZ-160 | 160KW | 8Kg/Minute | 11.5Kg/Minute |

| KQDZ-240 | 240KW | 12Kg/Minute | 17Kg/Minute |

| KQDZ-300 | 300KW | 15Kg/Minute | 21Kg/Minute |

Induction billet heating furnace technical advantages

- Our induction billet heating machine is with large power range, and a low-frequency level, so the heating depth is very good.

- Machine with simple operation method, high heating efficiency, low power consumptions, very easy to operate and use.

- With a digital control system, digital phase lock technology, to realize the frequency automatic tracking.

- Intelligent, modular installation, easier to operate and maintain.

- Adopting resonant frequency conversion technology, the efficiency of the whole induction billet heating furnace can reach more than 95%.

- It is more energy-saving compared to other traditional heating methods.

- The final heated product pass rate is much higher.

Induction billet heating furnace applications

- All kinds of different standard parts induction heating forging process.

- All kinds of different billets bar induction heating forging.

- Steel bar ends partial forging.

- All kinds of mold induction heating

- Bar induction preheating process.

How can I get a faster quotation?

We have been in the induction billet heating furnace field for more than 20 years. We will be glad to grow up together with all of our users always, so if you have any technical inquiries, you can leave a message on our website and also include the following information, so that we can fast know which model of our induction heating furnace is suitable for you.

- Your heated workpiece material, size, and drawings will be better.

- Heating efficiency, like how many pieces you want to heat in one hour?

- Your heating temperature requests.

- Your heating parts conditions.

- Your contact details.

Our service

- We can provide a free training service for all of your operators or your maintenance engineers.

- We can guide the user to do all kinds of different shapes and sizes of induction billet heating furnaces and give all of our full technical support including drawings.

- All of our induction billet heating furnace maintenance period is 1 year.

- We have a big company database and strong technical teams and can serve you 24 hours in time, to let our induction furnace run more smoothly in your factory.