What’s HVAC Refrigerant Distributor Induction Brazing Machine?

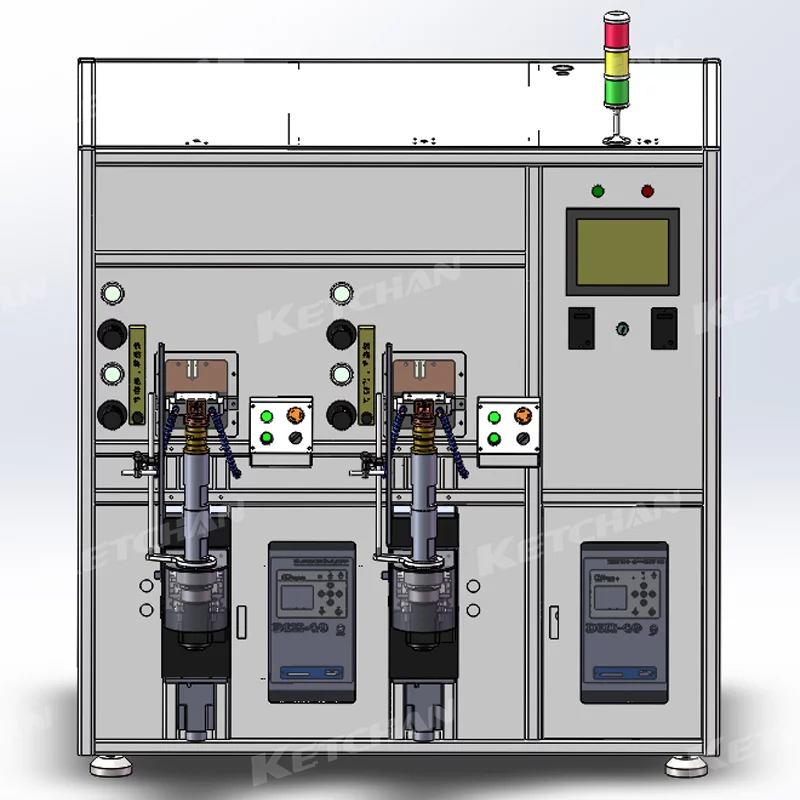

This HVAC Refrigerant Distributor Induction Brazing Machine is an automatic induction brazing process for brass shunts and copper capillaries, equipped with a set of automatic induction brazing machine tools, including an induction brazing system, cooling system, and mechanical mechanism.

The HVAC distributors induction brazing system mainly heats the brass shunt and the copper capillary to melt the welding ring to complete the welding process; the induction brazing control system controls the overall action; the mechanical action system fixes the product, locates the Z-axis of the tool, lifts, Positioning tooling rotation, etc. The cooling system mainly cools the induction brazing equipment and the induction coil.

How to do the HVAC Refrigerant Distributor Induction Brazing?

No. | Name | Description |

1 | Immersion Brazing Flux | Brass Shunt Dip Flux |

2 | Fit the brazing rings | Capillary fit brazing rings |

3 | Assembly | Insert the capillary into the distributors |

4 | Load brazing parts | The product is placed in the positioning tooling |

5 | Induction Brazing(rotate) | Induction brazed capillaries (simultaneous rotation, can be closed) for uniform heating |

6 | Cooling | After welding, wait a few seconds and spray air to cool the product |

7 | Take off the brazed part | Remove the product from tooling |

Induction Brazing HVAC Refrigerant Distributor applications

HVAC Refrigerant Distributor induction brazing machine data

Control method | Full digital embedded software control | |

Display method | 3.5-inch true color display, resolution 320×240 | |

Operating mode | Manual mode, automatic mode | |

Main chip | STM32F103 | |

Chip speed | 72MHz | |

Communication Interface | Db-9 and 4-pin aviation plug | |

Bus access | RS485.Profibus.CANbus | |

Power input | Input voltage | AC380 |

Rated current | 40A | |

Power Output | Rated Power | 25KW |

Working status display | Time, current, frequency, current curve | |

Working frequency | 10-50KHZ | |

Type of workpiece parameter | 10 kinds | |

Heating Method | Manual, auto | |

Automatic heating section | 5 pieces | |

Setting accuracy of heating time | 0.1S | |

What’s HVAC Refrigerant Distributor Induction Brazing Process?

According to the HVAC refrigerant distributor induction brazing technical requests, the induction brazing process can do as follows:

- PLC quantitative control, storage, and extraction of welding parameters such as welding heating current, heating time, delayed air injection time, and air injection time after welding. The touch screens can adjust all process parameters of the production process.

- The workpiece processing parameters can be stored in 30 groups, and the workpiece selection interface is password protected.

- The Control system should have an alarm device, equipment failure to timely alarm, and automatic display and storage of error information on the equipment, and alarm information can be queried.

- RS485 interface is configured to communicate with PLC.

FAQ

- What are your inducton brazing machine applications?

Our induction brazing systems are mainly used in the HVAC field for compressor copper tubes, condenser copper tubes, heat exchanger copper tubes induction brazing welding applications.

- How to choose a suitable induction brazing machine?

You can please let me have your brazing parts pictures along with the size, so that we can suggest to you suitable induction machine models.

- You are an end-user?

Yes, we are an end-users in the induction brazing field for more than 20 years.

- How can I get a faster quote?

You can leave a message to us with your heating parts details so that we can feedback to you in 2 hours.