Petroleum, medical, chemical, and other industrial transportation pipelines will use stainless steel pipes, which require certain hardness and wear resistance. The high-frequency brazing machine produced by Zhengzhou Ketchan is specially used for high-frequency brazing welding of aluminum pipes, steel pipes, stainless steel pipes, and other pipes.

Performance characteristics of stainless steel induction brazing machine

- The high-frequency chopping power adjustment technology is adopted to realize microsecond-level control, which greatly realizes the rapid adjustment and stability of the power output during the welding process.

- The output ripple is small, the oscillation current is stable, the joint is smooth and flat, and the size of the workpiece is accurate.

- The main components of the induction brazing equipment are imported, so that the function, quality and performance of the equipment are very stable.

- Non-standard customization is not only suitable for stainless steel pipes, but also for welding of various parts in the small household appliance industry.

- Heating power, time, heat preservation power, time and cooling time are independently adjustable.

- The induction brazing equipment is simple in structure, high in reliability, low in maintenance rate, and convenient for customers to maintain by themselves.

- In brazing, the combination of rapid heating and heat preservation functions is adopted, which not only realizes rapid heating, but also maintains heat preservation when the solder is melted, so that the solder can be fully utilized;

- In the process of work, it saves time and improves production efficiency. It realizes the functions of loading, preheating, welding, holding pressure, and unloading at the same time.

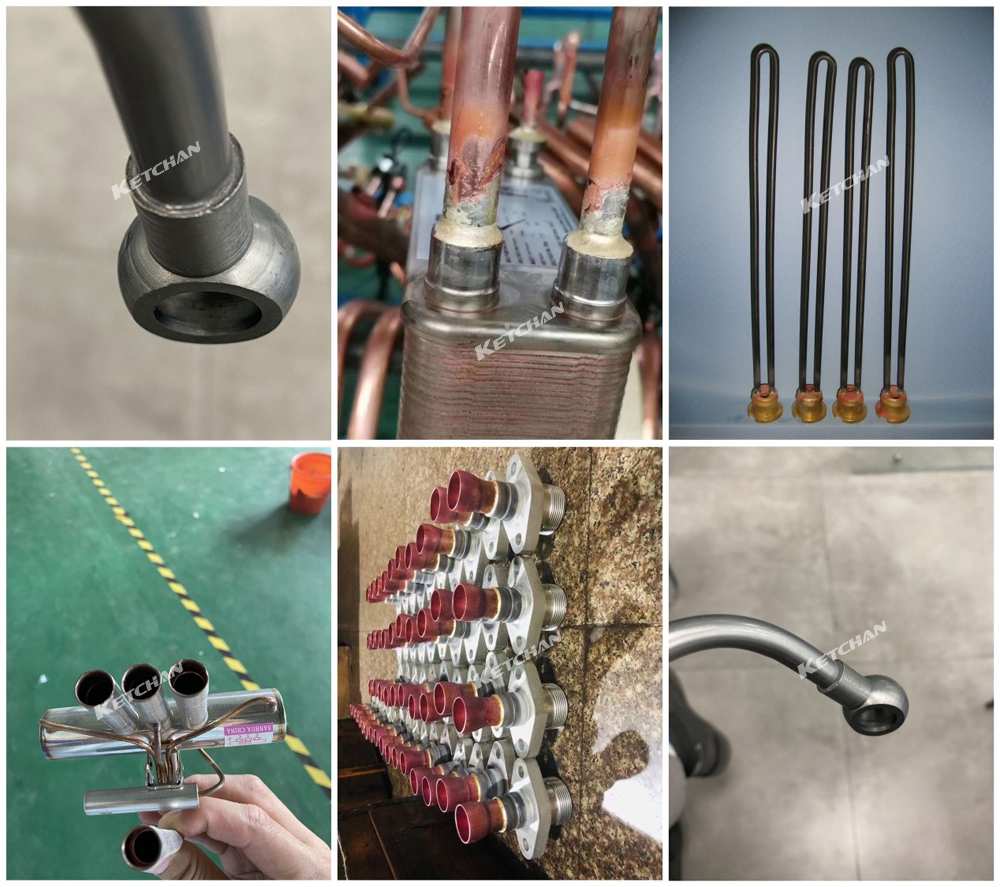

Applications of stainless steel high frequency induction brazing machine

- Induction brazing welding of steel pipes, stainless steel pipes, etc.

- Induction brazing of hardware stainless steel copper.

- Induction brazing welding of abrasive tools, drilling tools, alloy saw blades, drill bits, etc.

- Three-layer brazing of round, square, and other special-shaped flat stainless steel bottoms and aluminum sheets.

- Induction brazing of heating plates for heating plates, electric kettles, soymilk buckets, etc. in the small household appliance industry.

Unique advantages of stainless steel high frequency induction brazing machine

- Reliable and durable, stable operation.

- High efficiency and energy saving, high output power.

- The operation is simple and convenient, saving labor costs and improving production efficiency.

- High reusability and lower production costs.

- CNC design, the equipment does not need to be debugged.

- The welding method can be manual or automatic.

- It has constant current and power control functions, and optimizes the heating and welding functions of workpieces such as stainless steel pipes.

- Energy saving, energy saving, safety and environmental protection.

We can adjust the power of the equipment according to your different welding workpieces and processes to customize your stainless steel tube high-frequency brazing machine, CALL US NOW!

Tags:braze copper to stainless steel, brazing stainless steel joints, for Sale, induction brazing machines, induction brazing stainless steel, induction brazing stainless steel tubing joints, induction heater, induction heating, induction heating for brazing, induction heating machine, KETCHAN, KETCHAN Electronic, manufacturer, Manufacturers, price, stainless steel brazing equipment, stainless steel induction welding machine, supplier, Suppliers, Zhengzhou KETCHAN, Zhengzhou KETCHAN Electronic