What is induction hardening machine?

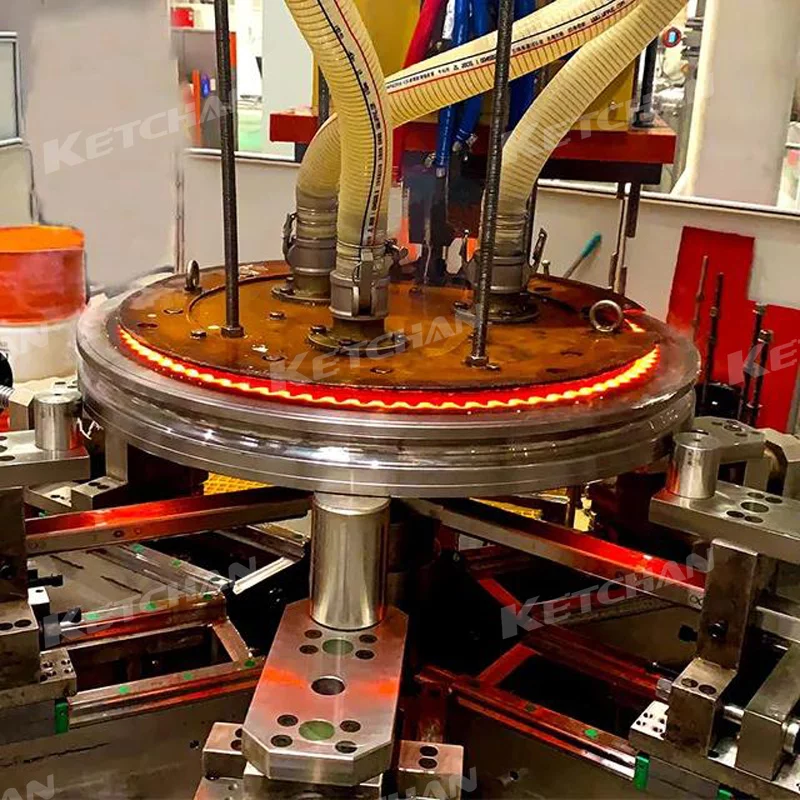

The induction hardening machine is mainly composed of an induction heating power supply, quenching control equipment (including inductor), and a CNC quenching machine tool. The induction quenching method is a main surface quenching method in the modern machine manufacturing industry, with good quality, fast speed, less oxidation, low cost, good working conditions, and easy to realize mechanization, automation, and a series of advantages. The appropriate induction hardening machine power supply and frequency (which can be super audio, intermediate, or high frequency) are determined based on the size of the workpiece and the depth of the hardened layer. The shape and size of the inductor mainly depend on the workpiece shape and quenching process requirements. CNC induction hardening tool can be customized as per different heat treatment workpiece sizes, shapes, and hardening requests. For parts produced in batches, especially in automatic production lines, special CNC hardening machine tools are widely used. In general, small and medium factories, due to a large number of workpieces, in less quantity, mostly use the universal CNC quenching machine tools.

In the Ketchan company, induction quenching power supply, CNC quenching machine tool, and the cooling system can be ordered together, saving time and money. Zhengzhou Ketchan has been in the induction hardening machine manufacturer fields for more than 20 years, we have matured technology and process, so we can guarantee the quality and at the same time, we can give you the good factory price level.

How to select a suitable induction hardening machine?

The induction hardening machine is the main metal workpiece heat treatment equipment, which is widely used in mining machinery, petroleum machinery, wind power machinery, railway traffic, and so on. At present, there are great differences in the type, model, price, and manufacturer of induction heating equipment in the market. How to select the suitable induction heating equipment has been a hot topic of concern. ZHENGZHOU KETCHAN will introduce some tips on how to buy induction heating equipment so that you can choose the right one.

- Before purchasing, users need to clearly understand their metal workpiece material, shape, size and production efficiency, process requirements, and so on, manufacturers are based on this information customize a set of induction heating technical proposals along with quotations to meet your production requirements.

- When purchasing, you should fully understand your configuration requirements, choose automatic induction heating equipment or semi-automatic, manual metal induction heat treatment furnace, and consider the operating environment (such as the terrain of the operation site, weather, etc.) to choose different types and specifications of induction hardening machines.

- The factory production volume also affects the induction hardening machine choice. According to the self, applications to choose different metal induction hardening machine specifications. If the monthly output is bigger can choose higher automated level induction hardening systems. If the output is less can consider choosing the simple structure induction hardening systems to arrange the investment much more reasonably.

- When selecting different brand induction hardening systems, better fully consider the market price, production capacity, market reputation, and service evaluation and then choose the suitable manufacturer.

- If it is convenient, factory face-to-face communication is necessary. In this way, can fully understand the manufacturer’s strength and also can understand better the induction hardening process.

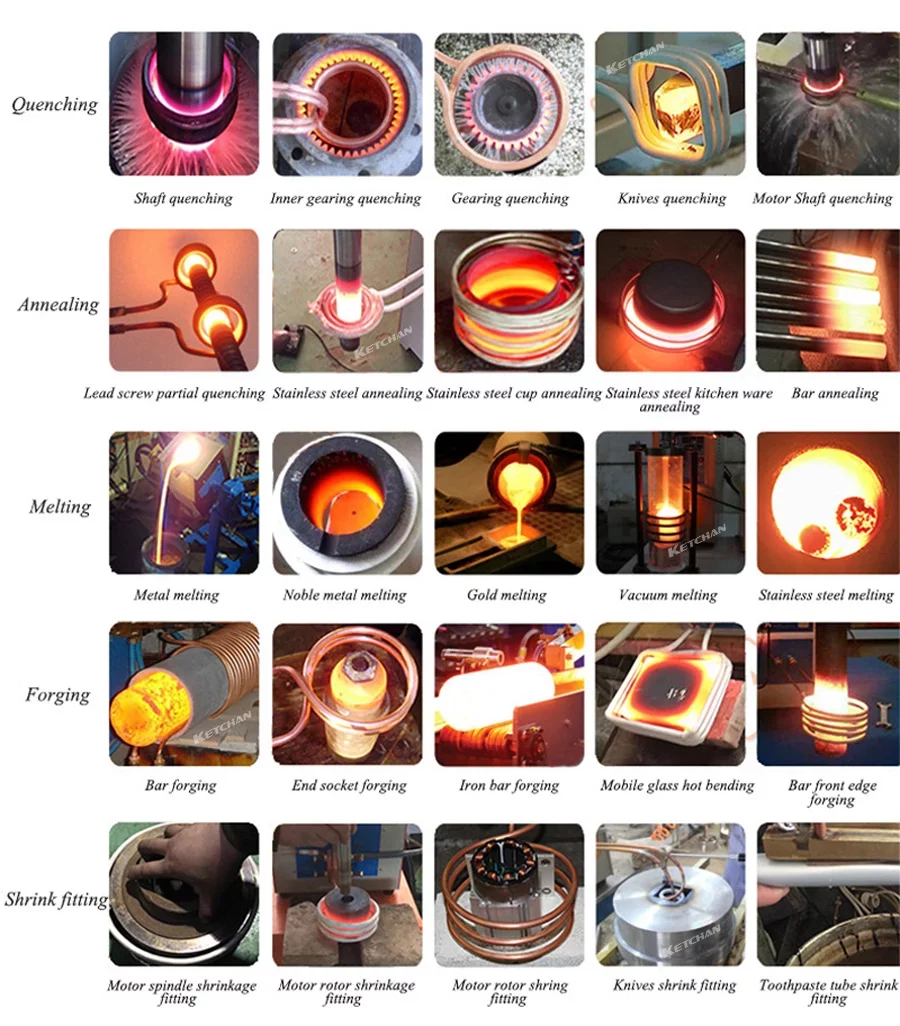

What is induction hardening machine application?

- ZHENGZHOU KETCHAN induction hardening machine is suitable for simple and complex metal workpiece induction heat treatment, including vertical CNC hardening machine tool, horizontal CNC hardening machine tool, Crankshaft hardening machine tool, and other customized CNC hardening machine tools.

- Complete functions: Our induction hardening systems can cover wide application ranges from the smaller parts to larger parts, for loading material, induction hardening, induction tempering, and unloading material. We focus on induction hardening system turn-key projects.

- Applications: Induction Hardening quenching gear, camshaft, drive shaft, crankshaft, torsion bar, coupling, rocker, drill, chain, boom, clutch, brake disc, steering rack, constant speed universal joint, three-column trough shell, shock absorber, bell shell, control rod, shaft sleeve and output shaft etc.

FAQ

- You are a manufacturer?

Yes, and we have been in the induction heating machines field for more than 20 years.

- What are your payment terms?

Pay 70% as advanced payment, before delivery, 100% T/T should be paid.

- How about the delivery time?

In 20-60 working days after getting your payment.

- How can I get a faster quote?

Leave a message to us, we will contact you once we see your message.

- Where I can see the induction hardening machine working video?

We have Youtube video room: Zhengzhou Ketchan Electronic Co.,Ltd – YouTube