Applications:

In the workpiece subjected to alternating loads such as torsion and bending, the surface layer is required to withstand higher stress or wear resistance than the core, and the surface of the workpiece needs to be strengthened. And today we focus on talking about the induction hardening of shafts.

Technical process:

With the combination of rapid heating and immediate quenching and cooling, through rapid heating, the surface of the steel to be processed reaches the quenching temperature, and it cools rapidly without waiting for the heat to reach the center, only the surface layer is quenched into martensite, and the center is still unquenched. Annealed (or normalized and tempered) organization with good plasticity and toughness, is the shaft induction hardening process.

Hardening methods:

Induction heating surface quenching (high frequency, medium frequency, power frequency), flame heating surface quenching, electrical contact heating surface quenching, electrolyte heating surface quenching, laser heating surface quenching, electron beam heating surface quenching, etc.

Induction Hardening Principle:

Put the shaft parts in the inductor made of hollow copper tube, after passing the medium frequency or high-frequency alternating current, an induced current of the same frequency is formed on the surface of the workpiece, and the surface of the part is rapidly heated (800-1000 degrees in a few seconds). , after the core is still close to room temperature, spray water cooling (or oil immersion quenching) to harden the surface layer of the workpiece.)

Shaft Induction surface Hardening advantages:

- The heating speed is extremely fast, which can expand the transformation temperature range of the A body and shorten the transformation time;

- After quenching, the s

- Surface layer of the workpiece can get extremely fine cryptocrystalline martensite, and the hardness is slightly higher (2-3HRC);

- The workpieces treated by this process are not easy to be oxidized and decarburized, and even some workpieces can be directly assembled and used after treatment;

- The depth of the quenching layer is easy to control and easy to automate.

The technical requirements for participating in this production activity are: hardness HRC60 hardened layer 0.7mm. After simple debugging, the actual production was carried out. Our 40kw ultra-high frequency induction heating equipment fully meets the production requirements.

Relate Products

-

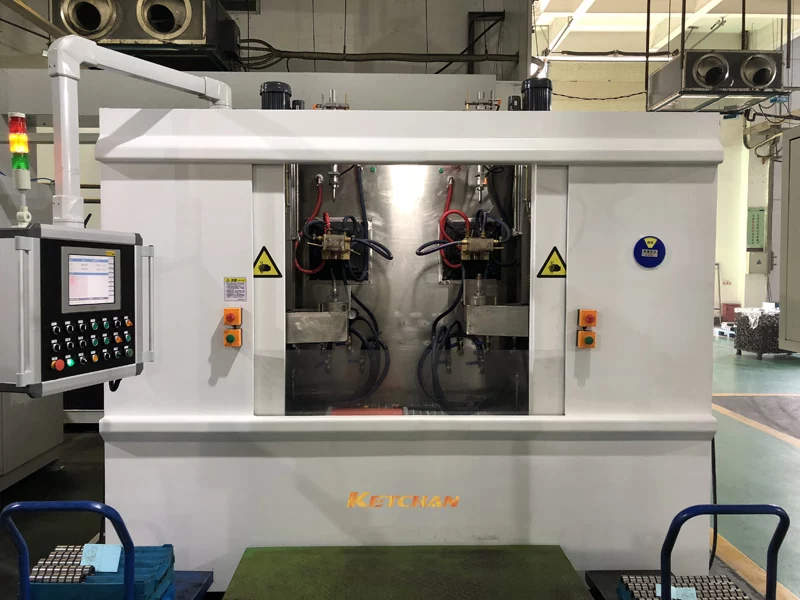

CNC Hardening System

Shaft CNC Hardening Machine Tool

-

CNC Hardening System

Vertical CNC Hardening Machine Tool

-

Induction Heat Treatment system

Shaft Induction Hardening Machine

-

HF Induction Heating System

High Frequency Induction Hardening Machine

-

HF Induction Heating System

Industrial Induction Heating Machine

-

UHF Induction Heating System

Ultra high Frequency Hardening Machine