What is induction hardening tempering?

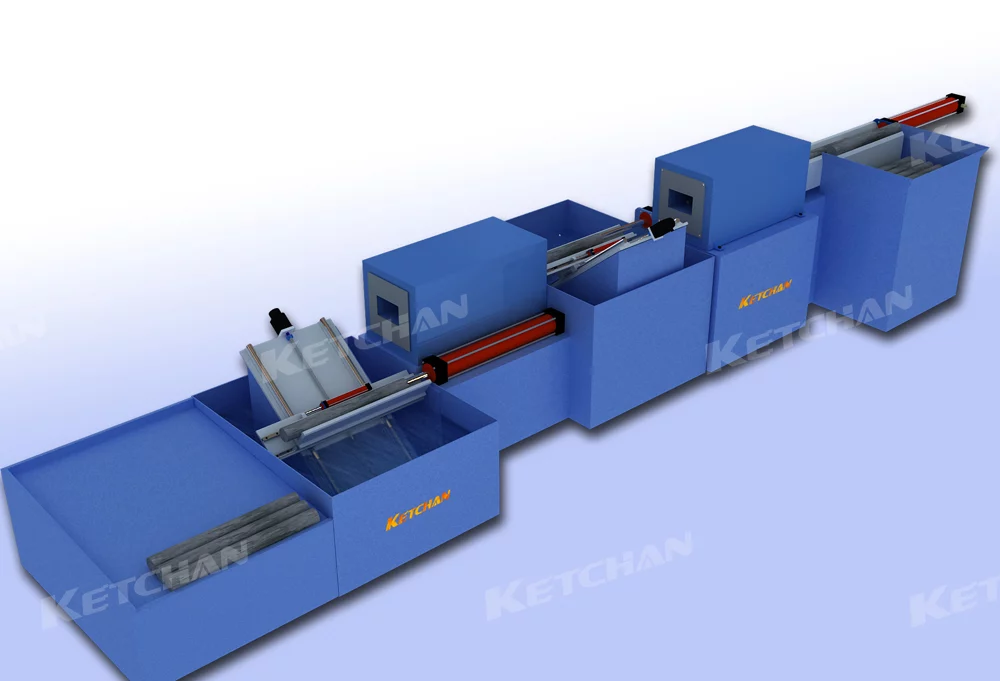

Induction hardening tempering furnace is a non-standard intermediate frequency induction heating equipment, which makes use of the characteristics of the ring effect and skin effect of intermediate frequency electromagnetic induction, aiming at the advantages of round steel fast heating, uniform temperature, and high automation. The complete equipment has automatic loading and unloading, automatic feeding and unloading, automatic temperature control, automatic spraying water quenching, and other functions,it is a complete set of round steel induction hardening tempering furnaces.

The complete induction quenching tempering system is mainly used for round steel, bar material, steel bar induction hardening, annealing, and tempering process. Assist in automatic control and automatic feeding equipment, realize the perfect combination of induction heating and automation, to achieve the complete induction quenching and tempering heating production line intelligent control.

What is induction hardening tempering furnace advantages?

- The startup success rate can reach 100%.

- The power factor of the rectifier is greater than or equal to 0.96

- The temperature interface can realize temperature closed-loop control.

- All digital, no relay control loop, so that the system is stable and has a reliable operation.

- With over current, over voltage, under voltage, lack of phase, water pressure, water temperature, and other complete protection, to ensure that any failure will not damage equipment components.

- Three phases of feed lines regardless of phase sequence can be connected arbitrarily.

- The integrated system, simple operation, and efficient production.

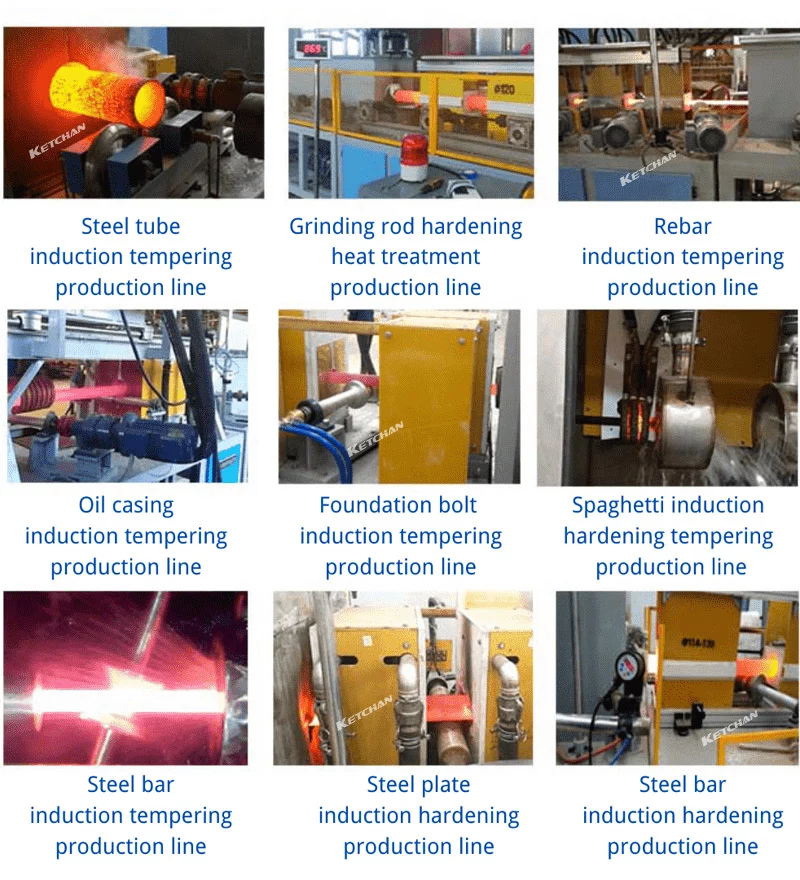

What is induction hardening tempering furnace applications?

Medium frequency induction hardening tempering furnace is widely used for online heating treatment of bar, round steel, square steel, and steel plate, as well as metal materials overall induction tempering and annealing.

How to do the induction hardening tempering process?

Medium frequency induction hardening tempering furnace has round steel automatic feeding → induction heating → cooling (quenching)→ induction heating (tempering)→ automatic blanking and has completed the whole induction quenching and tempering process function on the continuous production line.

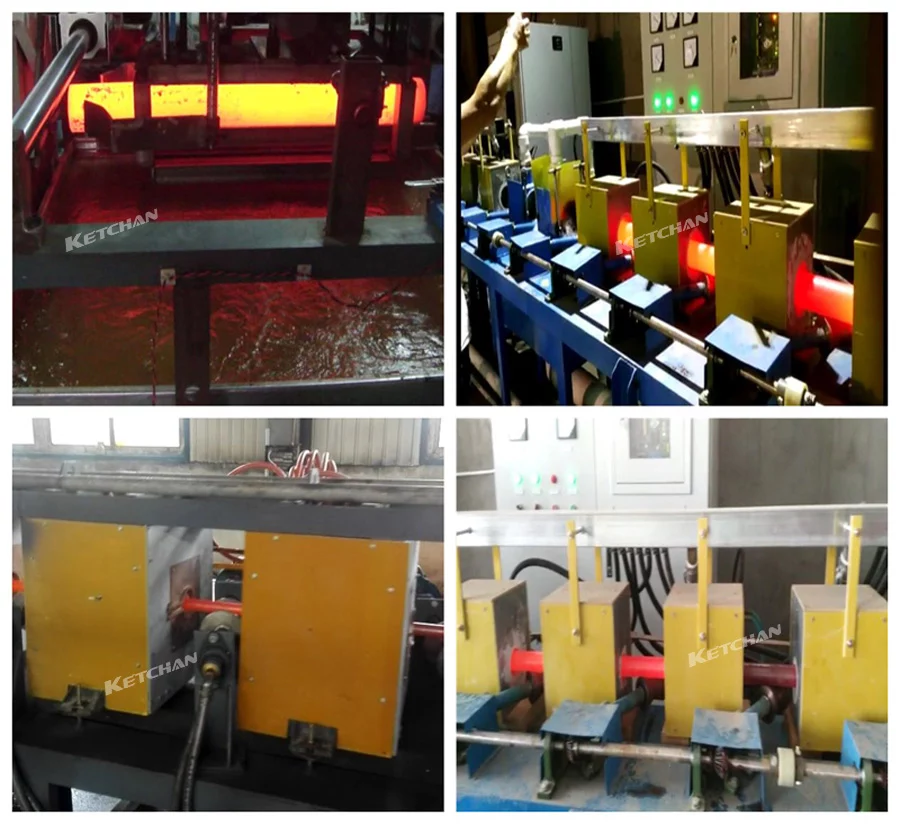

- The intermediate frequency induction hardening and tempering furnace will automatically load the round steel and lift it to the top material platform, and then send it in a rotating way through the conveying device.

- Medium frequency induction hardening tempering furnace induction heating through the conveying device steady speed operation, put the parts into the quenching induction coil, through the fixed infrared thermometer temperature measurement, do the parts of preheating→temperature measurement→temperature rising→temperature measurement control. When the quenching temperature is reached, the high-pressure water spraying device is used for cooling to complete the induction quenching process.

- After tempering and cooling of medium frequency heating and tempering furnace, the parts are sent into the tempering induction coil for tempering and then sent into the blanking area.

How to select a suitable induction hardening tempering furnace?

- The heated workpiece shape and dimensions

Round bar induction hardening tempering machine, bigger workpiece, round bar, solid bar, should choose the bigger power level, lower frequency level induction heating machine. The smaller workpiece, tubes, plates, and gears should choose the smaller power but higher frequency induction heating machine.

- The heated depth and area

Deep heating, large area, overall heating, should choose large power, low frequency induction heating equipment; Shallow heating, small area, local heating, should choose smaller power, higher frequency level induction heating machine.

- The requested heating speed

The higher heating speed should choose bigger power, lower frequency induction heating machine.

- The continuous working time

The longer working time should choose a bigger power induction heating machine.

- The connection wire distance between the inductor and heating machine

Long connection, even needs to use a water-cooled cable connection, should choose relatively large power induction heating equipment.

- Heating process requests

Generally speaking, for quenching, welding, and other processes can choose relatively smaller power, higher frequency induction machine; Annealing, tempering, and other processes, choose relative larger power lower frequency level induction machines; Red blanking, hot forging, smelting, etc., need good diathermy effect process, so the power should be selected high, the frequency should be selected low.

- Workpiece material

For a high melting point, the material should choose a bigger power level, the lower melting point should choose a smaller power level. Low resistivity material chooses a bigger power level, high resistivity chooses a smaller power level.

Wind power bolt Induction Hardening Tempering production line