How to design induction heating coil?

Induction heating coils plays a pivotal role in the entire induction heating industry. Regardless of high-frequency welding equipment, gear quenching equipment, high-frequency heating furnaces, intermediate frequency forging furnaces, etc., the induction coil is the heart of every machine. Then, for the design of the induction heating coils, we require precise positioning. The specific standards are as follows:

- The shape of the induction coil should be determined according to the shape of the heated workpiece surface. The production principle should make the copper tube in the induction part and the heating surface of the workpiece flat or equidistant, and the current direction between adjacent turns should be consistent.

- The gap between the small workpiece and the induction heating coil should be controlled at 1-3mm.

- The material should be a red copper tube with a diameter of 6 or more (the best wall thickness is 1mm), and a copper tube with a diameter > 10mm should preferably be a square copper tube.

- The electrical contacts connected to the machine should be polished to clean the surface oxide layer.

- Make full use of the proximity effect and notch effect of the current, and add a magnet if necessary.

- After the induction heating coil is made, it should be matched with the whole machine so that the frequency is within the specified range. The output waveform is correct.

How to use and maintain induction heating coil?

The main component of induction heating equipment is the induction heating coil, and the service life of the induction coil is also related to the use of the induction heating equipment. Through the right use and maintenance of the induction heating coils, we can make the service life of the induction coils longer. In the production process, it is best to prepare three sets of induction heating coils, one for production use, and the other two for standby. So what is the service life of the induction coils related to?

- Install correctly: The most basic requirement for the use of the induction heating system is correct installation, and the contact plate, whether it is a bolt, a cam, etc., must be close to the output end of the induction quenching transformer, and the contact surface needs to be clean and free of oxide skin. At the same time, the effective induction coils and the working gap must reach the specified value to prevent accidents such as short circuits.

- The workpiece for induction quenching and heating should meet the requirements of workpiece size and cleanliness: The size and process of the workpiece should also conform to the corresponding induction heating coils, and the workpiece’s hardening surface size and positioning surface should meet the process requirements. To prevent the induction coils from being damaged.

- Regularly check the effective ring size: The effective rings must be checked regularly, and if errors are found, they must be changed in time.

- Clean and wipe the working surface of the effective circle in time.

- The effective ring with the largest current should check the outlet water temperature regularly, and the outlet water temperature must not exceed 50℃.

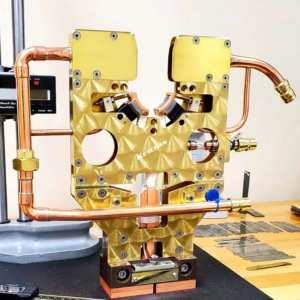

What is KETCHAN featured induction heating coil?

The characteristics of the induction heating equipment induction heating coil are that the effective ring conductive part is thick and the structure is relatively heavy. Generally, it is welded by multiple machined parts. Some inductors are also attached with a workpiece positioning device. At this time, The work can be loaded without relying on the quenching machine’s rotating center.

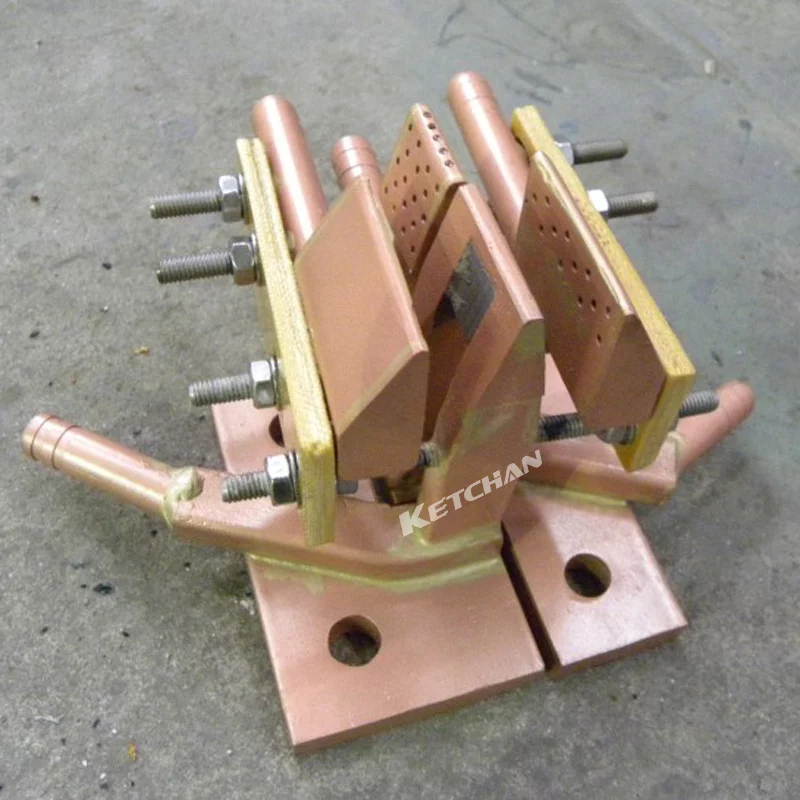

- Half ring crankshaft induction heating coil: It consists of an effective ring, a spacer, a side plate, a liquid sprayer, an interval positioning block, and other parts, and its core is an effective ring, which is composed of circumferential branches and axial branches.

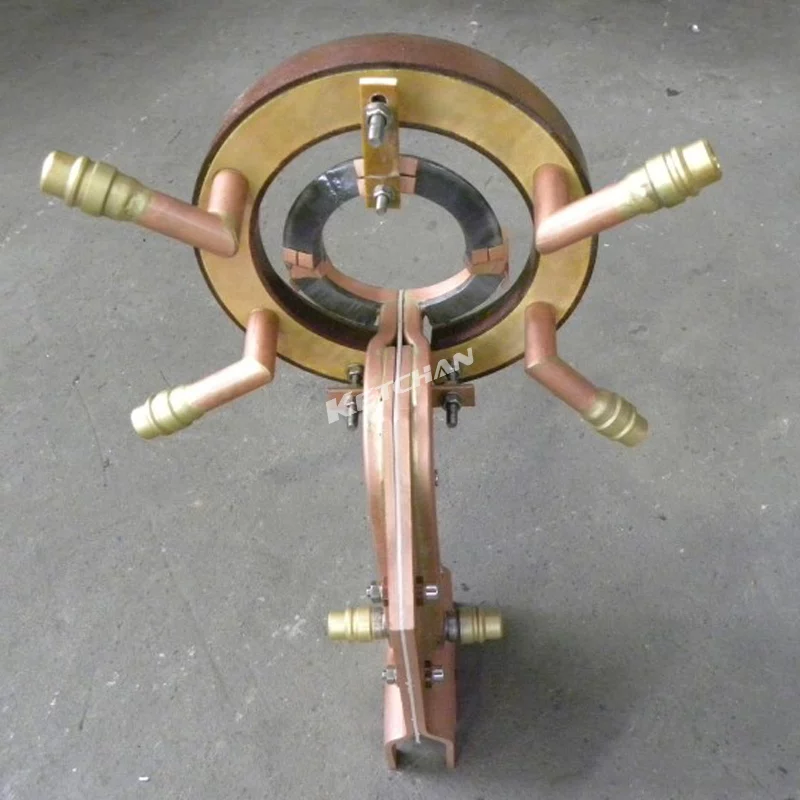

- Camshaft quenching induction coil: Because of its special geometry, the current frequency used has a decisive effect on the temperature of the peach tip. There are two types of camshaft induction heating coil: circular and profiling. Most of the engine cam induction heating coils are using circular effective rings.

- Cylinder liner inner surface quenching induction coil: Scanning quenching is generally used for quenching the cylinder liner inner surface. Due to the cylinder liner’s thin wall, when the inner surface is heated and quenched, there is an auxiliary liquid sprayer on the outer surface of the cylinder liner for cooling, which can reduce the deformation of the cylinder liner.

- Short cylinder type induction heating coil: It is an induction heating coil that heats a short cylindrical workpiece. The effective circle is divided into three layers. The upper layer heats the upper section, the middle layer heats the middle section, and the lower layer heats the lower section. The temperature of each section can be adjusted by adjusting the wrap Angle of each section. The effective ring of this structure can also be installed according to the requirements of different parts of the magnet, the lowest effective ring slightly changed, can heat the fillet and flange surface of the workpiece.

- Bell shell spline part induction heating coil: Its effective ring is divided into three sections, the upper section heats the workpiece cylinder upper section, the middle section is heated by two columns, and the column should be equipped with a magnetic guide; A magnetic conductor can also be added to the part of the lower forging heating shaft.

- Induction heating equipment has a semi-shaft primary heating inductor: a high-power medium frequency power supply is used to harden the semi-shaft hardened area at one time. In addition to improving productivity, this method can also be combined with a special quenching machine tool, combining heating, correction, and cooling on a quenching machine tool.

- For confirming the suitable induction heating coils, please let us know your heating jobs and also technical requests on, so that we can confirm the suitable models.