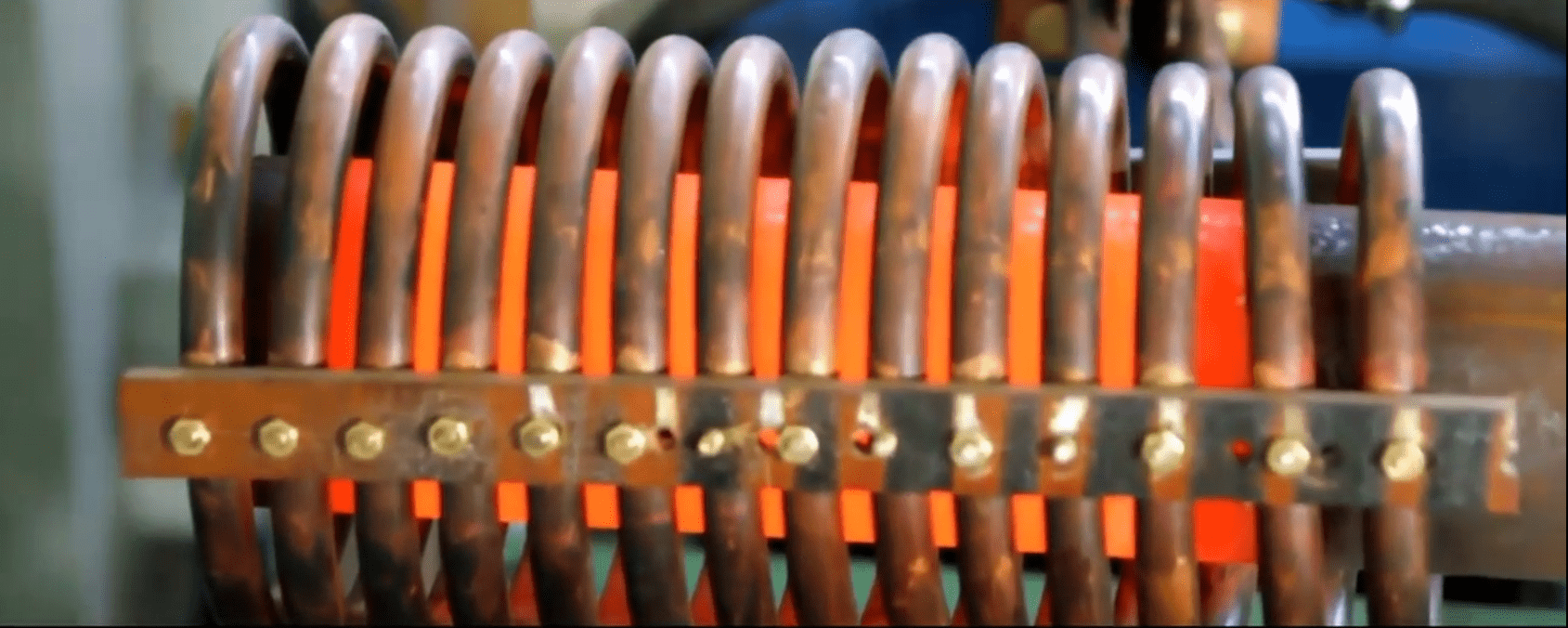

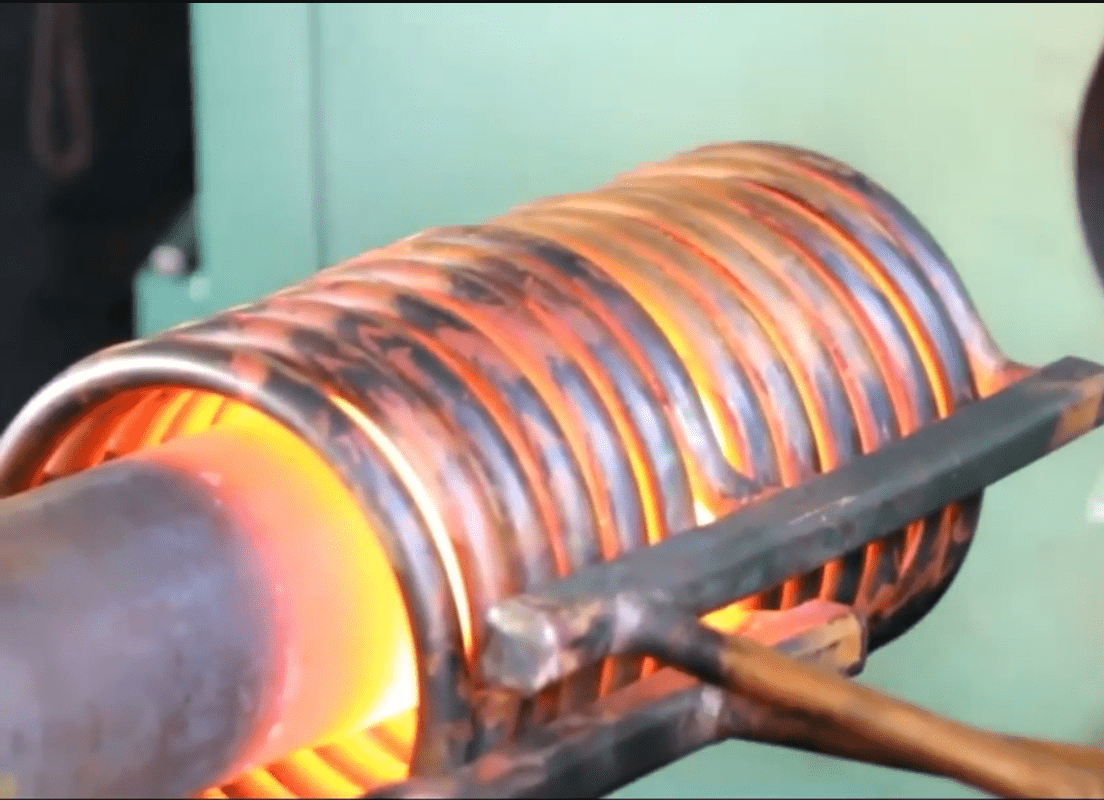

Induction heating for upsetting pipe tubing ends is an ideal technology for your tube/pipe upsetting needs. It provides rapid and even heating of the tube/pipe end for maximum upsetting quality. Multiple parallel coils allow for higher production rates and better temperature uniformity.

Some of the applications of induction heating for tube/pipe upsetting are pipe end normalizing after swaging, friction/arc weld pre-heat or normalizing, pre-heat for hard banding or upset forging, curing of paint, plastics, and other coatings, and heating for bending.

The pipe upsetting process is accomplished by heating the ends of the tubing in the upset furnace after which, the heated tube end is put into the upsetter. The tube is held in place by two dyes, and the upsetter forces the punch into the end of the heated tube, creating the upset.