Induction heating is an efficient heating method that is widely used in the modern spring steel wire industry for induction hardening tempering of spring steel wire and induction heating of springs for hot roll forming. Besides, It can be used for induction heating, induction hardening, induction tempering, stress-relieving, induction annealing, and relaxation of wires, rods, ropes, and cables.

Application Industry:

- Hot coil forming spring manufacturing

- Oil quenching spring wire

Technical Process:

Store material— Reverse feeding—medium frequency induction heating—high frequency induction heating–transmission—spring hot roll forming—oil quenching—drying—induction tempering heating —-cooling—collection

Equipment Parameters:

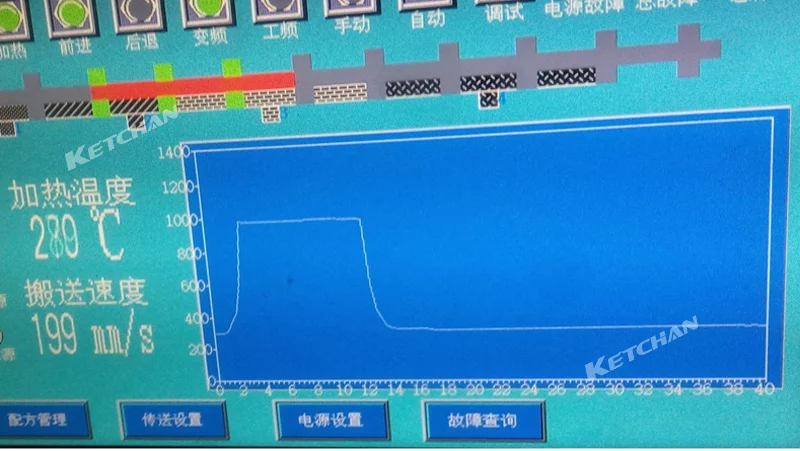

induction heating machine for spring steel wire preheating process | Medium frequency induction preheating spring steel wire l Frequency:10~15KHz l Power:300KW l Preheating temperature: 700℃ High frequency induction preheating spring steel wire l Power :300KW l Frequency:15-30KHZ l Heating temperature: 1000℃ |

Induction hardening of spring steel wire | Induction hardening of spring steel wire for preheating l Frequency:8~12KHz l Power:300KW l Temperature: 720℃ Induction hardening of spring steel wire for heating l Power:300KW l Frequency:20-30KHZ l Temperature:880 degree |

Induction tempering of spring steel wire | Induction tempering of spring steel wire for preheating l Power: 150KW l Frequency:3-5KHZ l Temperature:480℃ Induction tempering of spring steel wire for temperature insulation l Frequency:3~5khz l Power:30KW l Temperature: 500℃ |

Production Speed:

| No. | Wire diameter (mm) | Temperature(℃) | Heating speed(mm/s) |

|---|---|---|---|

| 1 | 14 | 1000 | 550 |

| 2 | 12.5 | 1000 | 699 |

| 3 | 11.8 | 1000 | 740 |

| 4 | 10.7 | 1000 | 704 |

| 5 | 9 | 1000 | 679 |

Results and Conclusions:

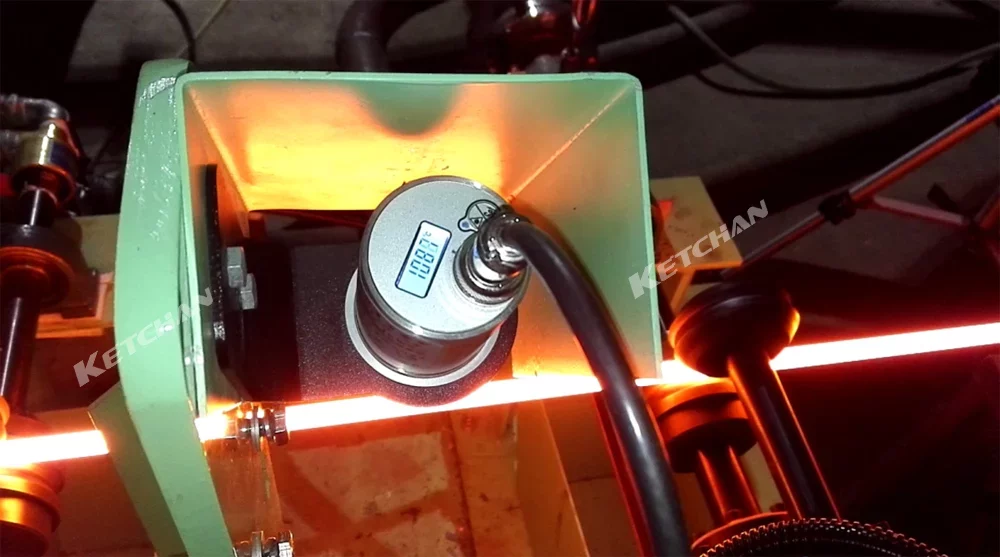

According to the production process, spring steel wire can be divided into two types: cold drawn spring steel wire and induction heating oil quenched spring steel wire. Among them, the oil quenched spring steel wire adopts digital intelligent intermediate frequency induction heating and IGBT super audio frequency induction heating power supply as the core of the heating equipment, adopts the closed-loop quenching and tempering temperature, and the closed-loop method of the tension of the steel wire. high efficiency, high quality products, and high consistency of performance.

Zhengzhou KETCHAN induction heating Hardening tempering equipment of spring steel wires has successfully put into production the oil quenched and tempered spring wire coil spring production line with a rate of 30-45m/min, which is widely used in the production of automobile springs.

If you are in the spring manufacturing industry, for more information, please contact us for asking about this application information. Below please find our Youtube videos of the spring steel wire induction hardening tempering process.

Subscribe to our Youtube for learning more about induction heating applications. Thanks.