What is induction heating system?

Induction heating, also known as electromagnetic induction heating, is a method used to bond, heat treating, induction welding, and soften metals or other conductive materials. For many modern manufacturing processes, induction heating systems are widely used in the manufacturing industries to increase heating speed and production efficiency.

How does the induction heating system work?

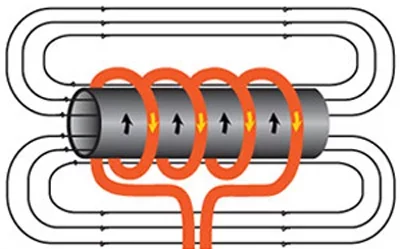

Induction heating is mainly using the magnetic field principle to heat, its heating system is mainly an induction coil, induction heating power supply, and the heated metal workpiece.

The induction heating power supply converts AC power into higher frequency AC power, transmits it to the induction coil, and an electromagnetic field is generated in the coil. Since the metal workpiece to be heated is also a conductor, the circles of magnetic field lines generated by the induction coil will directly penetrate the metal workpiece which is placed in the coil, forming a closed current loop. And the metal has less resistance, coupled with the higher current. When these high-current magnetic induction lines pass through the metal workpiece, the electrons inside the metal are very active, collide with each other, and rub against each other to generate heat energy, so as to achieve the metal part quick heating effect.

What is induction heating system application?

In modern manufacturing industries, induction heating systems are widely used in all kinds of metal heat treatment fields, mostly including the following fields.

- Induction hardening: Gear, crankshaft, camshaft, drive shaft, output shaft, torsion bar, rocker arm, universal joint, valve, rock drill, hub bearing, inner and outer ring raceway, etc induction hardening process.

- Induction tempering: Induction tempering can be performed on all hardened parts such as shafts, bars, and joints.

- Induction Brazing: Our brazing technology is widely used in the electrical industry. Universal application, mainly for components within generators and transformers, such as brazing of copper bars, bars, leads, wires, and short-circuit rings. at the same time. This technology are also used in the automotive industry for fuel lines and AC systems and brake components induction brazing. The aviation industry also uses induction brazing technology in the brazing of wind turbine blades, bushing sheets, and fuel and hydraulic systems.

- Induction bonding: For automotive parts such as car doors, hoods, fenders, mirrors and permanent magnets, etc. Induction heating can also be used for curing the bonding of composite/metal and carbon fiber/carbon fiber joints.

- Induction Annealing: Induction annealing and normalizing are widely used in the pipe industry. Can also anneal cables, steel strips, blades, and copper tubes.

- Induction preheating is widely used in the automotive, machinery, aviation, electrical, white goods, and shipbuilding industries. The main field of application is induction welding preheating.

- Induction forging: Induction forging is widely used in the metal and foundry industries for the billets heating, rods and rod ends heating. Induction heating systems available from KETCHAN Metals planned for forging include aluminum, brass, copper, steel, and stainless steel.

- Induction melting: Induction melting solutions are used in foundries, universities, laboratories, and research centers. Our solutions can be used to smelt almost everything from ferrous and non-ferrous metals to nuclear and medical/alloys for dentists.

What is the components of the complete induction heating system?

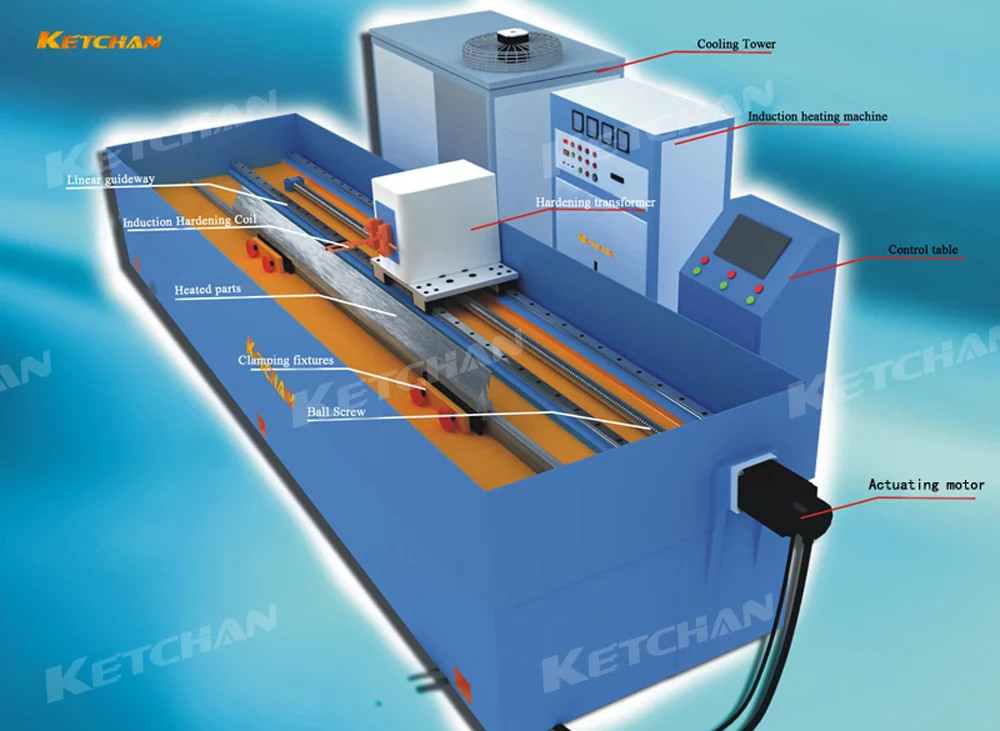

The complete set of induction heating and quenching system consists of induction heating power supply and load, CNC quenching machine tool, cooling system, and some other assistant device, etc.

- The induction heating power supply consists of a rectifier, inverter, and control. The rectifier, and inverter part adopt transistor IGBT. The control part adopts a digital system, which can complete the start of the induction heating power supply perfectly, and detect, adjust and protect the working state.

- The loading part consists of a ferrite quenching transformer and a capacitor to form an oscillation circuit. The capacitor also has good overload protection capability, and the overload current can also reach a certain level in the case of other harmonic currents.

- The CNC induction quenching machine tool adopts a semi-closed structure, which is basically composed of a machine body, a control system, a cooling system, and a quenching system. Adopt servo motor to drag the load to move axially, ball screw drive, Siemens CNC system control. The front part of the machine tool is the mechanical part, and the overall frame is welded by treated steel plates; The lower part is the quenching liquid return tank, and the upper part contains the lower top, which is connected with the geared motor to drive the parts to rotate, The upper center is used to clamp the workpiece, cables, cooling and quenching water channels are placed on the vertical mobile trailer, the rear part consists of an inductor, a capacitor cabinet and an output transformer to form a load system. Combined and securely mounted on a workbench. A hand wheel is installed on the plane of the towing frame, and the position of the lead screw in two directions can be adjusted by the hand wheel, and the relative position of the front and rear and left and right of the inductor can be adjusted. With this structure, the correct alignment between the inductor and the workpiece can be guaranteed. During continuous quenching, the servo motor drives the load to move through the ball screw.

Why use induction heating system?

Metal is an essential material in modern times, and it is used in almost every field. To turn it into a product of various shapes and functions, it needs to be processed. In order to process metal, it needs to be heated, because heating is the easiest way to change the shape of metal, and now there is a method that can heat metal rapidly, which is called induction heating. We are in the induction heating field for more than 20 years and have provided thousands of related induction heating system turnkey projects already in China and abroad.

How to select the suitable induction heating system?

In order to choose the suitable induction heating systems, we need to know:

- Your current heating method?

- Your heating parts details, and drawings will be appreciated.

- Heating speed, heating temperature, heating purpose requests.

- How many pieces do you want to heat in one hour?

- What are your induction heating applications?

Leave a message to me and I will suggest suitable induction heating system models for you timely.