Induction Heating History

Induction heating technology was started in 1831, by the inventor named Faraday. In the second half of the 19th century, induction heating technology began to be used in actual production – “conductor heating”. The field of application of the original induction heating technology was only in metal melting.

With the development of metal melting applications, surface quenching of steel began to appear in 1927. Mainly heat treatment of the crankshaft and cylinder barrel. Solid-state high-frequency power supplies began to be used in 1967. Nowadays, induction heating technology has developed from low-frequency devices to high-frequency devices, and the efficiency has been continuously improved. It is believed that the efficiency of induction heating technology will be higher in the future.

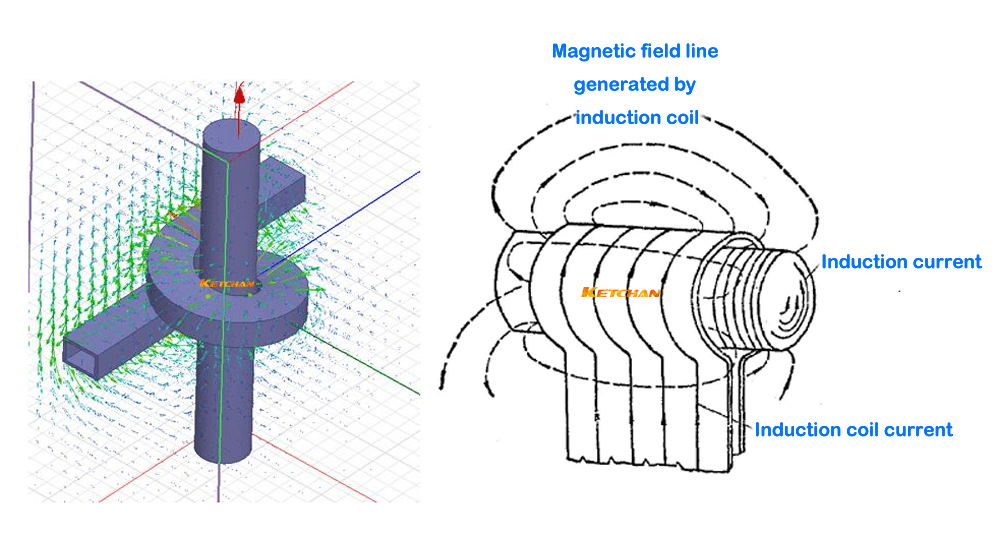

The most important effect in induction heating

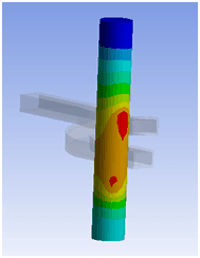

When alternating current is applied to the conductor, the current distribution along the conductor cross-section is uneven, and the maximum current density appears on the surface layer of the conductor. This current accumulation phenomenon is called the skin effect. It can be said that the alternating current generates an induced electromotive force in the conductor, and the magnitude of the induced electromotive force is gradually weakened from the inside to the outside. In turn, the current density is strengthened from the inside to the outside in the cross section of the conductor.

Due to the skin effect, the induced current in the workpiece is unevenly distributed, resulting in uneven heat generation in each part of the workpiece. A large amount of electrical energy close to the surface is converted into heat energy, while the internal current is small, the heat generation is also small, and the internal temperature rises It mainly relies on the external surface energy to enter by conduction. Therefore, if the power of induction heating is large, the heating time is very short, and the conduction method is too late to conduct to the inside of the workpiece. There are strict surface heating requirements in quenching and other processes, and the heating time is very short. Short, sometimes the temperature of the surface of the workpiece is very high, it has been burned red, or even melted, while the inside is still low temperature.

Industries and products involved in induction heating

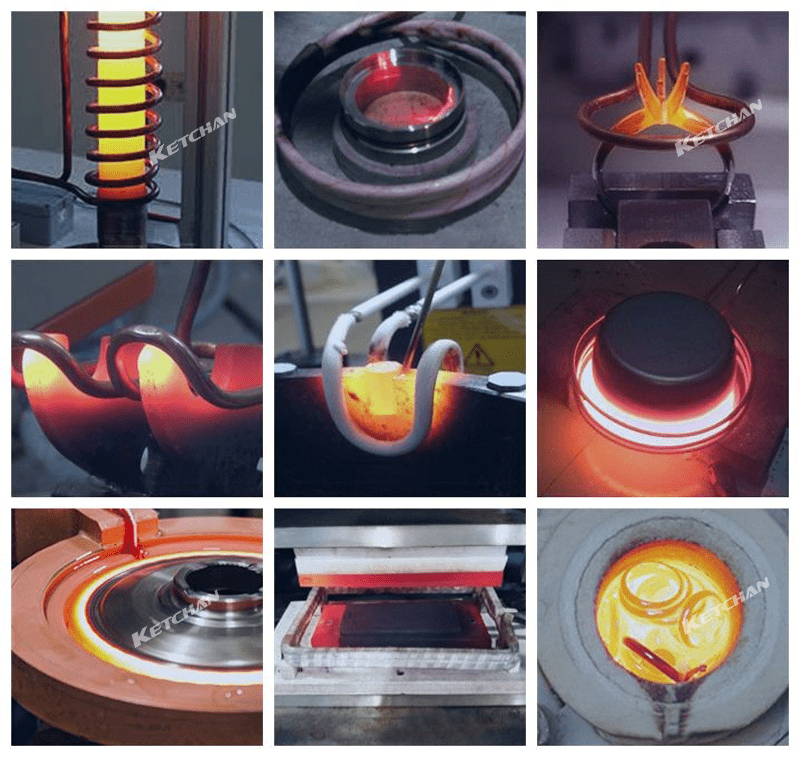

Induction heating power supplies are clean, energy-efficient, and easy to automate. The innovation and development of induction heating technology are in line with my country’s requirements for industrial transformation and upgrading and are consistent with the goal of establishing a low-carbon, green and energy-saving society.

- Electric furnace: continuous galvanizing furnace, tunnel furnace, walking beam furnace, annular furnace top charging melting furnace, round aluminum melting furnace, tilting holding furnace, vacuum arc remelting furnace, electro slag remelting furnace, vacuum induction melting furnace, vacuum precision casting furnace, induction condensing shell melting furnace, vacuum air brazing Welding furnace vacuum heat treatment furnace vacuum degassing furnace quenching: quenching machine tool.

- Annealing: On-line annealing system for air-conditioning copper tubes.

- Heat treatment: gear heat treatment.

- Shaft heat treatment preheating: strip steel billet heating Injection molding machine.

- Hot Assembly: Hot Assembly machine.

- Welding: induction brazing equipment.

- Forging: forging and curing of metals such as copper and aluminum.

- Bonding: car door cover.

- Plasma: Use high-frequency equipment to generate plasma. Optical fiber, ceramics, nanomaterial applications.

- Post Heat: Improves Cable Insulation.

- Straightening and Leveling: Deck Straightening and Leveling Locomotive Nose

- Tempering: Tempering of auto parts.

With the continuous development of induction heating technology and the unremitting efforts of many engineers of Zhengzhou KETCHAN, our company is now a high-tech enterprise with “full digital induction heating technology” as the core, and provides customers with various professional welding Equipment|Quenching Equipment|Forging Equipment|Smelting Equipment|Electromagnetic Induction Heating Equipment.

Tags:induction heater, induction heating, induction heating definition, induction heating formula,induction heating system, induction heating frequency range, induction heating history, induction heating how it works, induction heating machine, induction heating manufacturer, induction heating supplier, induction heating technology, KETCHAN, KETCHAN Electronic