What’s industrial induction heating machine?

An industrial induction heating machine is a kind of three-phase power frequency alternating current, after rectification into direct current, and then change the direct current into an adjustable current, supplied by the capacitor and the alternating current flowing in the induction coil, in the induction coil to produce high density magnetic field lines, and cut the metal material in the induction coil heating machine.

Why choose an industrial induction heating machine?

The industrial induction heating machine adopts imported Siemens IGBT solid state power module and advanced frequency conversion technology and has a unique cooling system, to ensure that the machine can work continuously for 24 hours under high power, improving the performance and quality of equipment.

- Constant power output, faster-melting speed, and power saving effect are more obvious.

- Zero voltage sweep software start, more adaptable to frequent start-up requirements.

- The production operation is simple, flexible material in and out, a high degree of automation, and online production can be realized.

- Workpiece heating speed, less oxidation, and decarburization, high efficiency, good forging quality;

- Workpiece heating length, speed, and temperature can be precisely controlled; Uniform heating of workpiece, a small temperature difference of core table, high control precision;

- Inductor furnace body integration design, different inductor design has quick change joint, simple and convenient replacement;

- All-around energy-saving optimization design, low energy consumption, high efficiency, lower production cost than coal burning;

- In line with environmental standards, small pollution, but also reduce the labor intensity of workers.

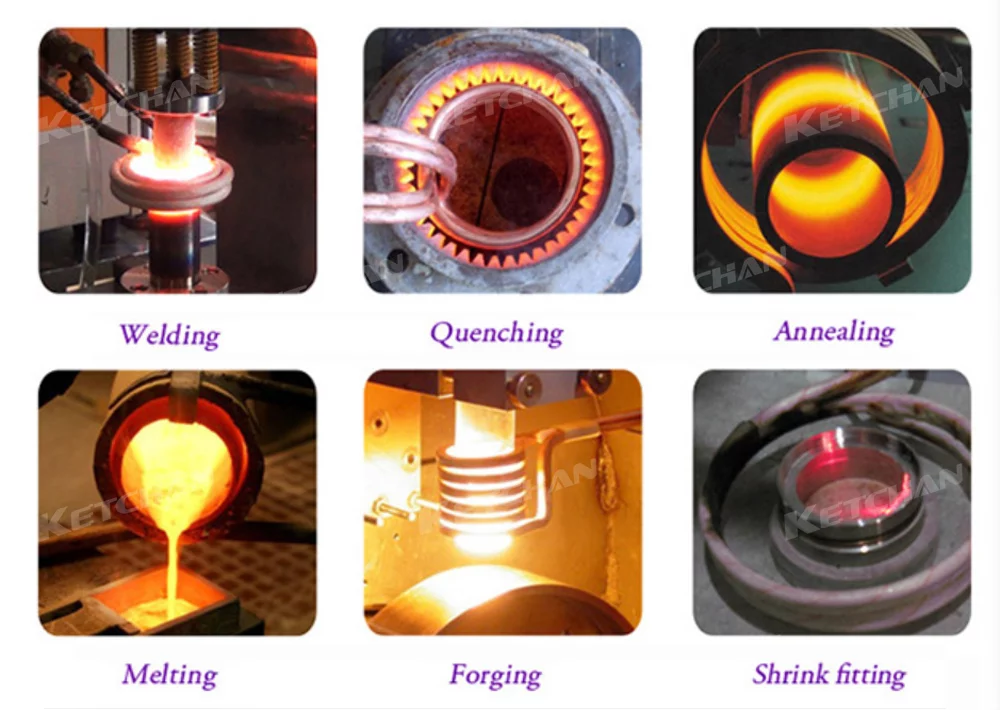

What’s an industrial induction heating machine application?

High frequency industrial induction heating machine is mainly used in the metal surface heat treatment and induction braze welding process.

- Heat treatment( Metal surface induction hardening)

It is mainly through the workpiece heating and other processing to make the hardness of the metal material changes, the specific application is as follows:

- Induction hardening all kinds of hardware tools, hand tools. Such as pliers, wrench, hammers, ax, screwdrivers, scissors (garden scissors), and so on.

- Induction hardening all kinds of automobile and motorcycle parts. Such as crankshaft, connecting rod, piston pin, sprocket, aluminum wheel, valve, rocker arm shaft, transmission shaft, small shaft, fork, and so on.

- Induction heat treatment of various power tools. Such as gears, shafts;

- Machine tool industry: Such as machine tool surface, machine tool guide rail induction quenching;

- All kinds of metal parts, machining parts. Such as shaft, gear (sprocket), CAM, chuck, fixture induction quenching;

- Hardware mold industry. Such as small mold, mold accessories, mold inner hole induction hardening quenching;

- Induction Brazing Welding(braze welding, silver brazing, copper brazing)

It is mainly by heating to a certain temperature to melt the solder, so as to connect two metals of the same material or different materials together, the specific application is as follows:

- Induction welding all kinds of hardware tool welding: diamond tools, grinding tools, drilling tools, alloy saw blade, carbide turning tools, milling cutter, reamer, planer, woodworking drill, etc.;

- All kinds of metal mechanical parts induction brazing welding: metal bathroom products, refrigeration copper accessories, lighting accessories, precision mold accessories, metal handle, egg beater, alloy steel, and steel, steel and copper, copper and copper equivalent metal or dissimilar metal silver welding, brazing;

- The heating plate welding of the electric kettle (electric coffee pot) is mainly used for brazing stainless steel flat bottom.

Industrial Induction Heating Machine Applications

How to choose a suitable industrial induction heating machine?

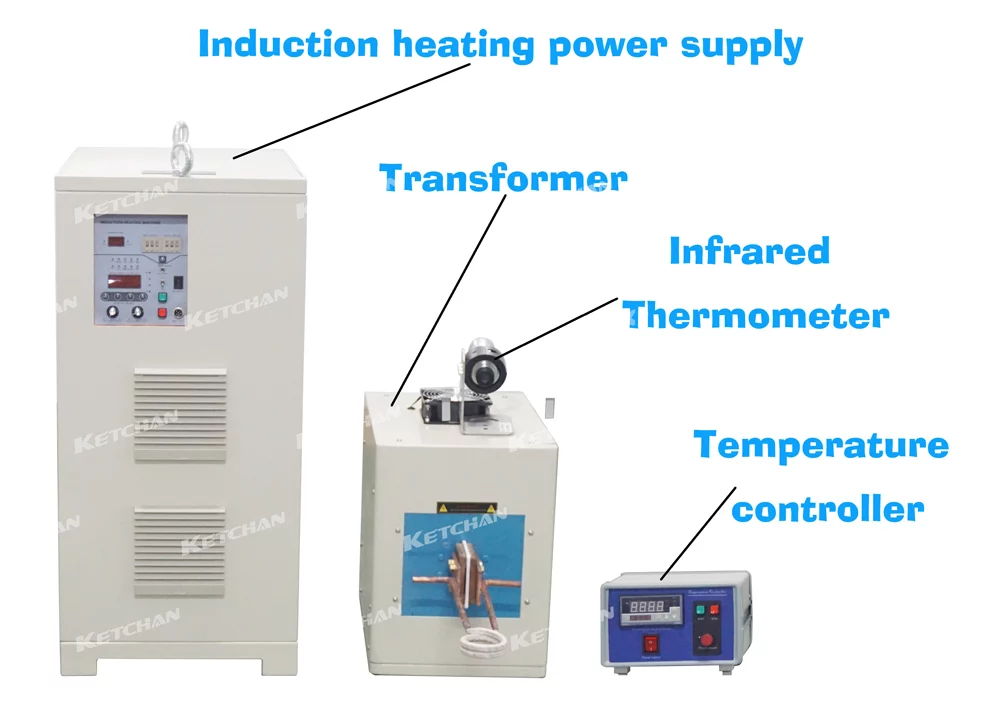

Zhengzhou Ketchan can provide a 15-300KW industrial induction heating machine, and also can customize a 400-1000KW high frequency industrial induction heating machine power supply. Below are our standard industrial induction heating machine specifications models.

| Model | Max Input Power | Oscillating Frequency | Input Voltage | Memo |

|---|---|---|---|---|

| KQG-15 | 15KW | 20-80KHZ | 220V 50HZ/60HZ; 380V 50HZ/60HZ ; 460V 60HZ; 480V 60HZ, Can customize voltage, power, frequency, etc. | Can do automatic and manual power supply. Add temperature measurement system. With timer 0.1-99.9S |

| KQG-25 | 25KW | |||

| KQG-35 | 35KW | |||

| KQG-45 | 45KW | |||

| KQG-70 | 70KW | |||

| KQG-90 | 90KW | |||

| KQG-110 | 110KW | |||

| KQG-140 | 140KW | |||

| KQG-160 | 160KW | |||

| KQG-240 | 240KW | |||

| KQG-300 | 300KW |