What is KETCHAN linear table induction brazing machine?

Zhengzhou KETCHAN is one of the leading induction brazing systems manufacturers in China, and these years according to the market requests, we have developed a series of superstar induction brazing systems, including a linear table induction brazing machines. It is developed for the smaller AC distributors, points liquid head induction brazing cases. Because of its high brazing efficiency, uniform finished products, good melting depth, perfect brazing result, and lower noise, it is widely used by Panasonic, Gree, Midea, Hisense, Haier, Aux, and so on. Compare with the flame brazing condition, it can save energy 1/3. Induction brazing speed is about 12000 pieces/ hour in real production.

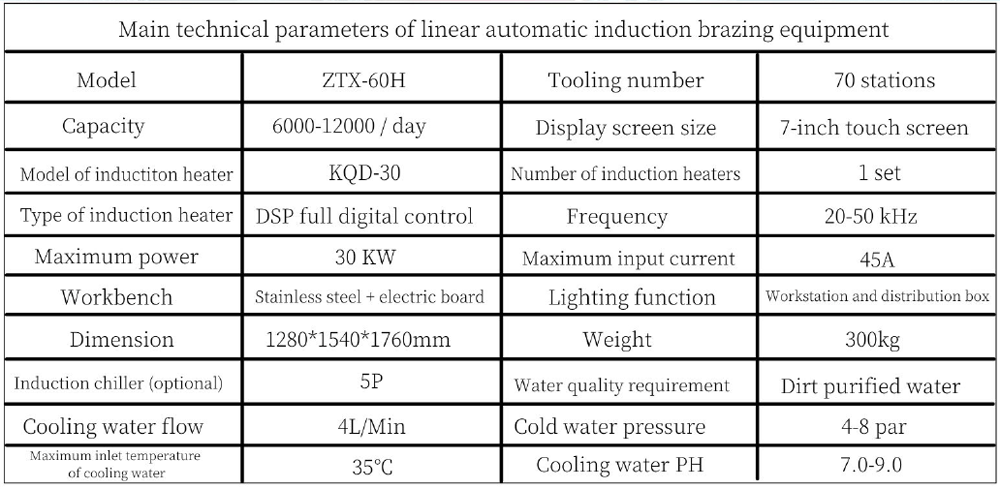

The complete linear table induction brazing machine consists of a portable induction brazing machine, a siemens digital control unit, mechanical frame part, industrial chiller, and induction coils parts.

For different users different applications, the induction machine may have some difference, so please leave message to us about your brazing parts details, so that we can quote you soon accordingly.

Why use KETCHAN linear table induction brazing machine?

- High efficiency

KETCHAN‘s linear table induction brazing equipment in the welding Gree 2, 3, 4 hole distributor efficiency is other equipment and welder can not be compared with. A straight-line machine can replace 3-4 welders’ work. The equipment can weld 900-1200 products per hour, and the equipment can work continuously for 24 hours. It only takes an ordinary worker to operate, workers only need to place the products in place, and the equipment is automatically welded and blanked in the assembly line form.

- High Quality

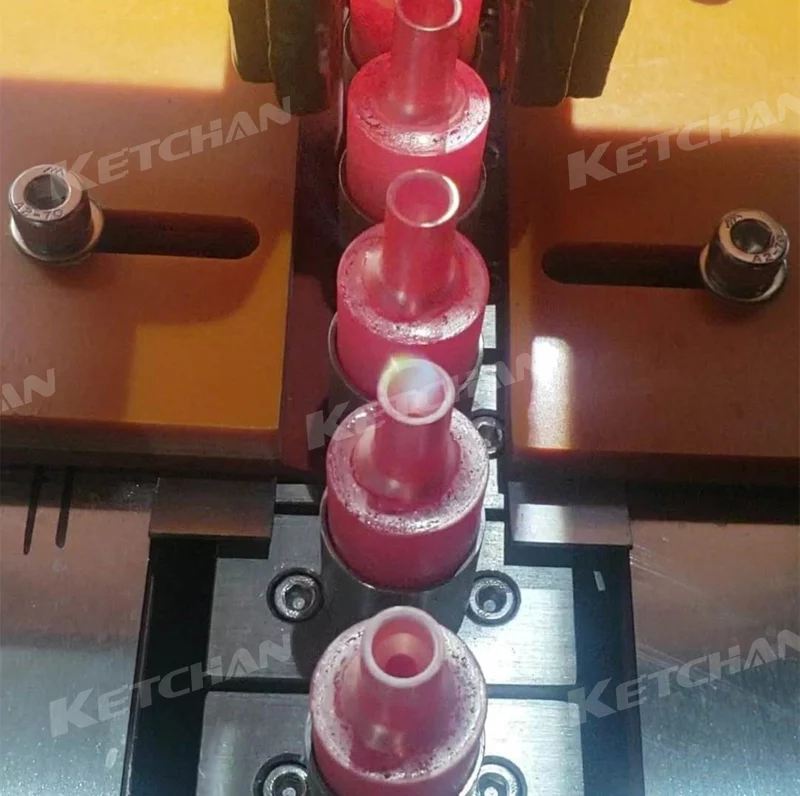

The principle of KETCHAN’s linear table induction brazing machine is to heat the product through electromagnetic induction, the magnetic field can completely penetrate the workpiece, so as to ensure the workpiece’s heating uniformity. Therefore, the distributors welding depth can be 100% to the bottom, and there are fewer faults, these are things that automatic flame welding and manual welding cannot do. The straight-line equipment welding distributor surface oxidation less, simple ultrasonic cleaning can be ok.

- Energy saving, good environment, and safety

Compared with automatic flame welding, linear table induction brazing can save about 1/3 of energy, it is the real data that the user actually measured with the electricity meter. Linear equipment in the welding process basically does not produce pollution gas, noise is very small, in line with the environmental assessment standards. Besides, it does not need to lay complex gas pipelines, which not only improves the workshop environment but also reduces safety risks.

- High stability and reliability

KETCHAN’s linear table induction welding equipment actively adopts user feedback information, and timely improvement, after several product generations constantly updated, has been standardized, mass production.The linear equipment is equipped with a digital induction heating power supply to ensure welding reliability and stability. The Japan imported chain is used to ensure the smooth operation. The structure is constantly optimized in the design. For the purpose of simplicity and practicality, the hidden trouble is avoided as far as possible to ensure the equipment’s high stability and reliability.

What is Linear table induction brazing machine applications?

At first, this linear table induction brazing machine is developed for induction brazing welding the 2 holes, 3 holes,4 holes air conditioner brass distributors and becaus of its uniform brazing result and fast mass production speed, now it is widely used for the HVAC industries uniform single welding parts, large production requirements parts induction brazing welding solutions.

How to select the suitable linear table induction brazing machine?