Medium Frequency Heating Equipment Technical data

ZHENGZHOU KETCHAN digital medium frequency heating equipment power 20KW-500KW, frequency range 1KHZ-40KHZ.

Medium Frequency Heating Equipment Technical advantages

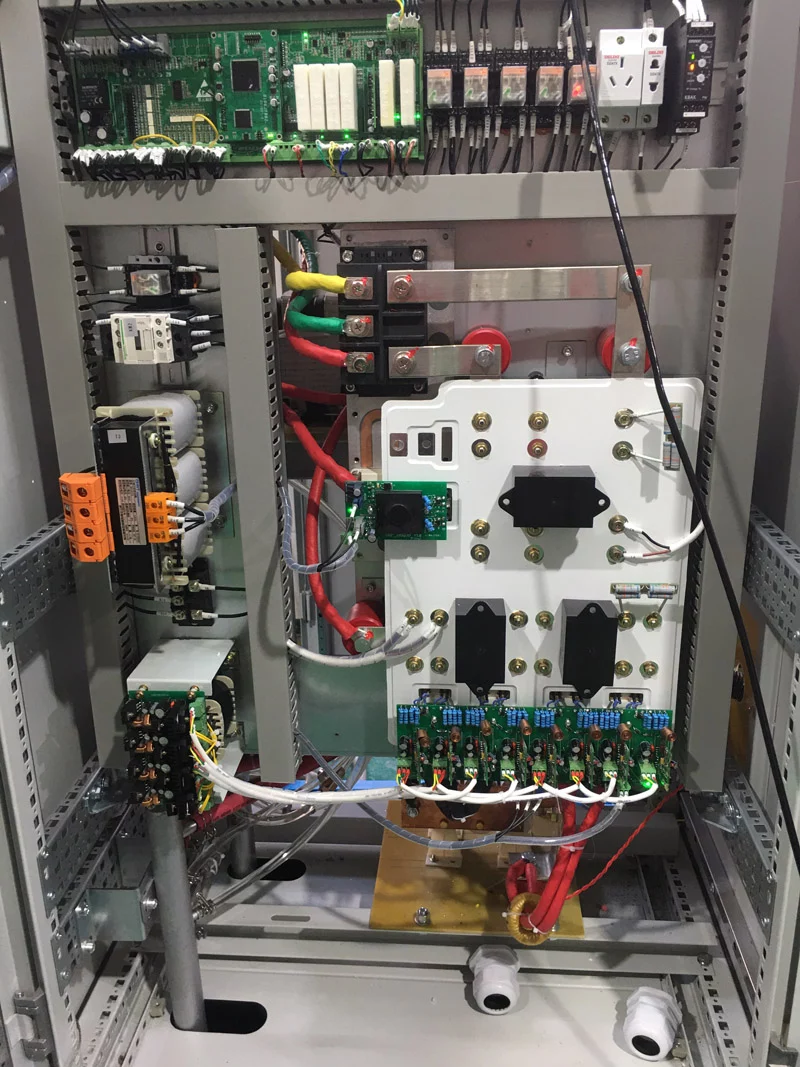

Medium frequency heating equipment adopts full digital frequency tracking technology so that IGBT always works in zero open states, the inverter power factor is always maintained at more than 95%, and the use of composite motherboard structure makes the whole inverter unit without absorption loop, the inverter power is greatly improved.

- Structural characteristics:

- Imitation Weichert case, high strength, long life.

- Fully enclosed design: industrial-grade IP54 protection

- Temperature and humidity regulation and air conditioning: to ensure the constant working environment of components.

- Safety bolt: Prevents unauthorized opening of the cabinet to ensure the safety of equipment and personnel

- Water and electricity separation: cooling water and electrical separation, to ensure electrical and personnel safety.

- Electric control characteristics:

- Full digital control: DSP main control chip, full digital control power, and frequency locking, control accuracy greatly improved.

- Optical fiber transmission: completely solve the electromagnetic interference problem.

- Complete isolation of control circuit: complete isolation of peripheral equipment and main control circuit, safe and reliable.

- Suction layer bus: laminated bus design with patented technology can effectively reduce the dc bus distribution inductance and ensure the safety of inverter devices.

- Perfect protection function: over voltage, over the current, short circuit, under-voltage, missing items, water shortage, frequency limit, and other protection functions.

- Rich external interfaces: external power control, start and stop control, software control, and other interfaces.

- Human-computer interaction features:

- Industrial touch screen: all parameters can be viewed and operated on the screen, and all Chinese prompts, are convenient and fast.

- Test mode: it can judge the power and frequency in advance to prevent the workpiece from burning out due to improper process parameters.

- Load matching indicator: according to the existing working condition, it can remind the user of the current working condition matching state and give the adjustment scheme.

- Heating time display: the real-time display of the current heating time, convenient for customers to adjust the whole induction heating process.

- Multiple control modes: constant current, constant power, constant temperature control, and programmable control, users can choose different control modes according to different process requirements.

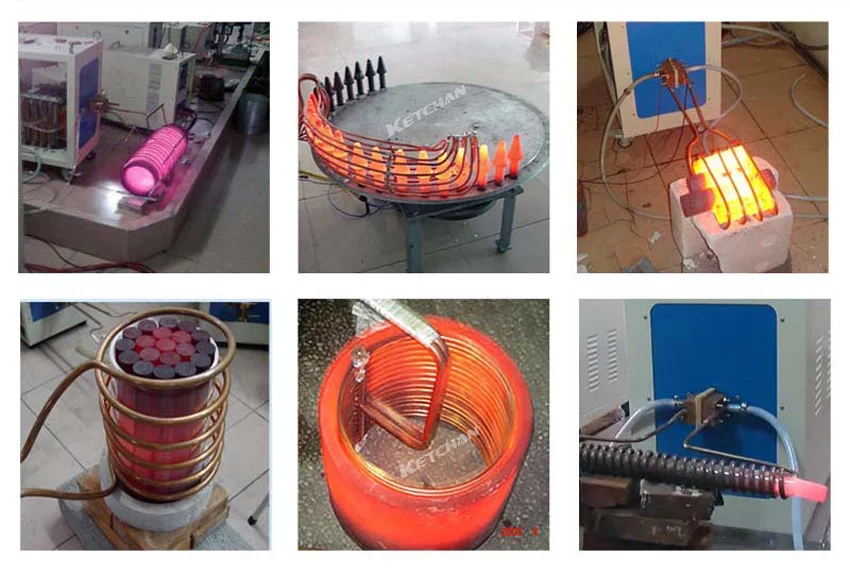

Medium Frequency Heating Equipment Application fields

Medium frequency heating equipment is mainly used in the metal bars induction forging process and also medium frequency metal melting process.

Medium freqyency heating equipment in the induction forging case:

- Forging heating (diathermy of bar, round steel, square steel, steel plate), heating, quenching blanking;

- Steel online heating, steel plate local heating;

- Online forging of metal materials (heating before precision forging, extrusion, rolling and shearing of gears, semi-shaft connecting rods and bearings),

- Spray heating of pipes, bearing, motor rotor, motor aluminum shell, automobile axle and so on.

- Induction heating forging and forming of various hand tools.

- Hot upsetting of standard parts, fasteners (such as high strength bolts, nuts, etc.), hot bending of U bolts.

- Brazing steel, brazing tool tempering, forging, extrusion heating.

- Forging of stainless steel tableware.

Medium frequency heating equipment in the metal induction melting case:

- Induction smelting steel, alloy steel, special steel, cast iron and other ferrous metal materials;

- Zinc, gold, silver, copper, aluminum, lead, tin and other non-ferrous metal induction smelting and heating, induction heat preservation.

- Can adapt to all kinds of different metal parts smelting requirements.

What are solid state induction heating machine applications?

- Induction Brazing: Induction brazing welding cutting tools, drilling tools, cutting tools, woodworking tools, turning tools, brazing bits, brazing reamer, cutter, drill bit, saw blade serrate, glasses frame, steel pipe, copper pipe welding, same of dissimilar metal welding, compressor, pressure gauge, stainless steel pot, relay contact composite materials with different welding transformer winding copper wire welding, storage (gas filling mouth of welding, the welding of stainless steel meals, kitchen utensils and appliances).

- Induction heat treating: Gear, machine tool guide rail, hardware tools, pneumatic tools, power tools, hydraulic parts, ductile iron, auto parts, internal parts, and other mechanical metal parts (surface, inner hole, local, integral) induction quenching, induction annealing, stainless steel pot products stretching.

- Induction hot forging: Standard parts, fasteners, master pieces, small hardware, straight shank twist drill, overall, local heating and twist drill of hot upsetting the following round steel, hot-rolled, diameter 100 mm to the annealing of metal, stretching, modeling, embossing, bending, smashing head, wire nail, stainless steel products (wire) heating type annealing, stretching, rise, thermal expansion.

- Other induction heating fields: aluminum plastic tube, steel plastic tube, cable, wire heating coating, metal preheating coating, semiconductor single crystal growth, heat matching, bottle mouth heat sealing, toothpaste skin heat sealing, powder coating, metal implanted plastic, food, beverage, pharmaceutical industry used aluminum foil hot sealing.