What is a medium frequency heating system?

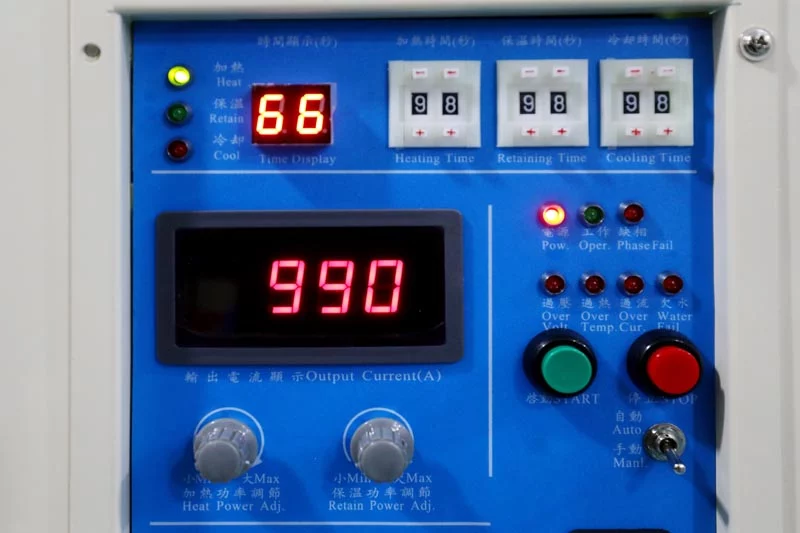

Medium frequency heating system adopts IGBT power device and ZHENGZHOU KETCHAN’s fourth-generation variable current control technology based on parallel resonance. In this technology, the power, and frequency conversion control independently, IGBT switching device and amorphous inductor are adapted to form the high frequency chopper circuit to adjust power, using IGBT parallel resonant and frequency automatic tracking technology to obtain accurate soft switch control inverter process, makes the medium frequency heating system work reliability under high power is greatly increased, and improved the machine power level, makes the 100% equipment transient load rate is achieved.

What are the main componets of the medium frequency heating system?

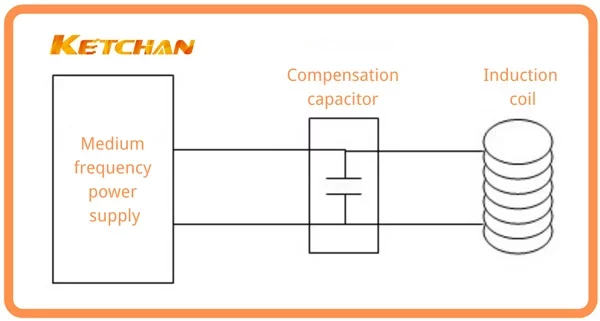

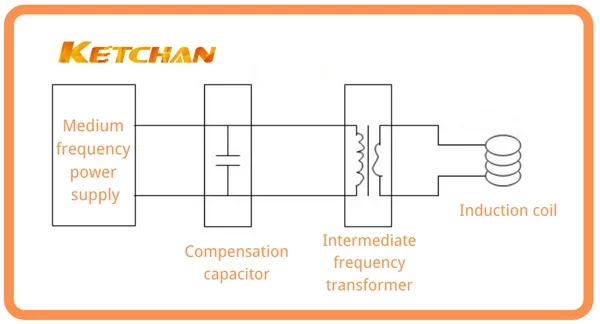

Medium frequency heating system series power supply all use the parallel resonant circuit, according to different application occasions, can choose direct output or output with intermediate frequency transformer, the basic structure, and composition areas the following two:

This structure is most commonly used, such as medium-frequency forging furnace, medium-frequency melting furnace is all using this structure, simple equipment structure, low loss, high efficiency, and low manufacturing cost.

Also, in this structure, the induction heating coil is relatively long, usually with a 3 – 10 meters long copper tube winding system.

As the intermediate frequency power supply directly output, so the maximum voltage on the induction coil is 550V, and it is not isolated from the main power, so the induction coil must be well insulated, and can not be directly exposed to the air.

This structure is also more commonly used, such as vacuum melting furnace, and intermediate frequency induction quenching. In this structure, by changing the ratio of the intermediate frequency transformer, different output voltage and induction coil current can be obtained to adapt to different requirements.

In this structure, the induction coil is isolated from the main electricity, so the induction coil has good safety, and low insulation requirements and even the copper tube can be directly exposed. But due to the increase in the manufacturing cost of the medium frequency transformer, so the equipment cost is high, and the intermediate frequency transformer is larger, but also increased a certain amount of energy loss. The lower the frequency, the larger the medium frequency transformer, the higher cost, and the greater loss.

Medium frequency heating system power supply + capacitor + medium frequency induction coil

Medium frequency heating system power supply + (capacitor + medium frequency transformer) + induction coil

What are the main features of the medium frequency heating system?

- Medium frequency heating system power supply, a structure using parallel resonance, control using our company’s fourth-generation inverter control technology, using IGBT as the main power device.

- The frequency range is large, ranging from 0.1KHZ to 20KHZ, and can be matched according to the size of the specific heating workpiece or the depth of the induction forging requirements.

- Adopting the traditional intermediate frequency parallel resonant structure, the load matching is simple, and the equipment has high efficiency and a high utilization rate.

- Adopt our company’s fourth-generation inverter control technology, all soft switch precision control, equipment with high reliability, and low maintenance rate.

What is the medium frequency heating system application?

The medium frequency power supply is mainly used for heating occasions requiring induction forging. Like:

- Induction heating and forging standard parts.

- All kinds of metal materials induction smelting.

- Motor rotor heating assembly.

- Tube ends heating and expanding.

- Mould induction forging.

- Shaft medium frequency induction hardening.

- Weld preheating or post-weld tempering.

What is the medium frequency heating system application?

The medium frequency power supply is mainly used for heating occasions requiring induction forging. Like:

- Induction heating and forging standard parts.

- All kinds of metal materials induction smelting.

- Motor rotor heating assembly.

- Tube ends heating and expanding.

- Mould induction forging.

- Shaft medium frequency induction hardening.

- Weld preheating or post-weld tempering.

What is medium frequency heating system data sheet?

| Model | KQZ-10 | KQZ-15 | KQZ-25 | KQZ-35 | KQZ- 45 | KQZ- 70 | KQZ- 90 | KQZ- 110 | KQZ- 160 | KQZ- 240 | KQZ- 300 | KQZ- 500 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Input power | 10Kw | 15Kw | 25Kw | 35Kw | 45Kw | 70Kw | 90Kw | 110Kw | 160Kw | 240Kw | 300Kw | 500Kw |

| Output voltage | 70-520V | 70-550V | 70-550V | 70-550V | 70-550V | 70-550V | 70-550V | 70-550V | 70-550V | 70-550V | 70-550V | 70-550V |

| Input power supply | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ |

| Input power supply | Three phases 380V-480V 50/60HZ | |||||||||||

| Oscillating frequency | 100HZ-20KHZ, according to customer’s heated parts to choose best frequency range. | |||||||||||

| Duty cycle | 100%, 24 hours continuous working ability. | |||||||||||

| Memo | Our standard medium frequency heating system is a three-phase 380V input voltage, suitable for 50 or 60HZ; Three-phase 400V, three-phase 415V, three-phase 440V, three-phase 460V, and three-phase 480V intermediate frequency power supply can be customized. Also can be customized three-phase 220V intermediate frequency power supply | |||||||||||