What is KETCHAN's medium frequency induction heating generator?

Medium frequency induction heating equipment working principle is to put a metal cylinder into an induction coil which has alternating medium frequency current, the metal cylinder has no direct contact with the induction coil, and the electric coil itself has a very low temperature, but the surfaces are heated to redness and even melt, and the redness and melting speed as long as adjust the strength of the size and current frequency can be achieved.

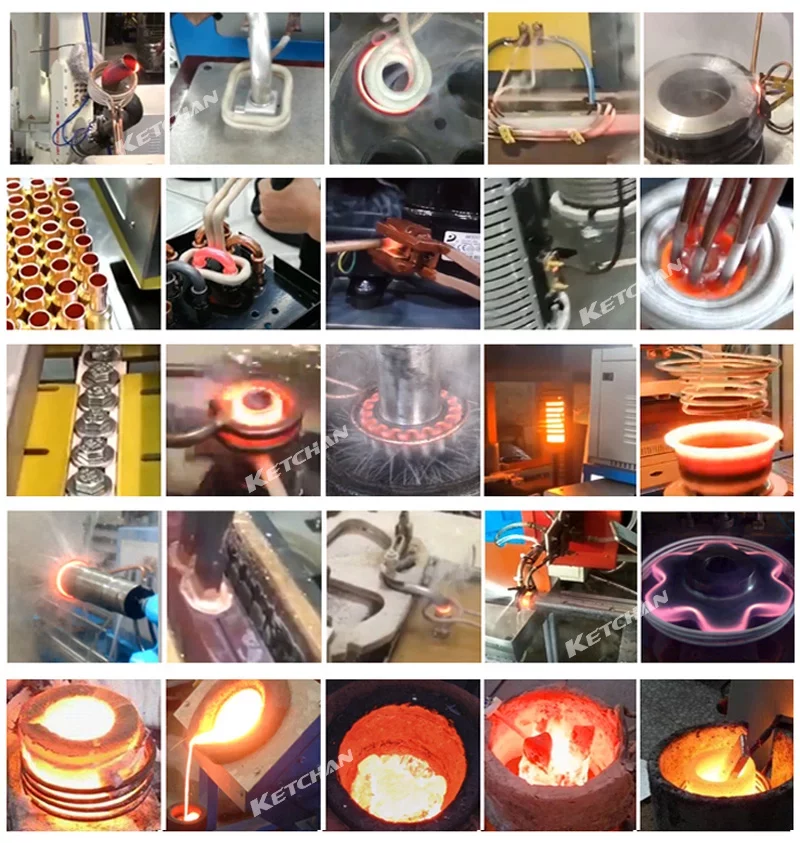

What is a medium frequency induction heating generator application?

Medium frequency induction heating generator has the advantages of small volume, lightweight, high efficiency, excellent thermal processing quality, and favorable environment, is rapidly eliminating coal-fired furnaces, gas furnaces, oil furnaces, and ordinary resistance furnace is a new generation of metal heating equipment.

The Medium frequency induction heating generator is the main equipment for casting, forging, and heat treatment workshops. Its stability, reliability, and safety are the guarantees of normal and stable operation of the casting, forging, and heat treatment production line. Medium frequency induction heating furnace has a good development prospect in the field of thermal processing, such as the main production of forging heating furnace, diathermy furnace and used for: diathermy, rolling, forging, bending, heat treatment (quenching), welding and other processes of induction heating.

- Induction brazing welding: drill, turning tool, reamer, milling cutter, drill, and stainless steel pot bottom of different materials of composite welding.

- Induction forging: Fasteners, standard parts, auto parts, hardware tools, copper bars, twist drill hot upsetting hot rolling, etc.

- Induction hardening: Shaft, gear, sprocket, machine tool guide rail parts quenching, and so on

- Induction annealing: Metal wire pipe annealing, hydraulic parts, auto parts, knife and scissors pliers, stainless steel pot annealing, and so on.

- Induction melting: Gold, silver, copper, lead, and other precious metals.

What is medium frequency induction heating generator data?

| Model | KQZ-10 | KQZ-15 | KQZ-25 | KQZ-35 | KQZ- 45 | KQZ- 70 | KQZ- 90 | KQZ- 110 | KQZ- 160 | KQZ- 240 | KQZ- 300 | KQZ- 500 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Input power | 10Kw | 15Kw | 25Kw | 35Kw | 45Kw | 70Kw | 90Kw | 110Kw | 160Kw | 240Kw | 300Kw | 500Kw |

| Output voltage | 70-520V | 70-550V | 70-550V | 70-550V | 70-550V | 70-550V | 70-550V | 70-550V | 70-550V | 70-550V | 70-550V | 70-550V |

| Input power supply | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ | Three phases 380V-480V 50/60HZ |

| Input power supply | Three phases 380V±10%,360-480V 50/60HZ | |||||||||||

| Output oscillation frequency | 200HZ-20KHZ, according to the user’s requirement. | |||||||||||

| Duty cycle | 100%,24 hours continuous working. | |||||||||||

Why use a medium frequency induction heating generator?

- Medium frequency induction heating generator with large power, low frequency, good diathermy. High efficiency, energy saving, simple operation, easy installation.

- Automatic arbitrary adjustment, improves capacity. Manual, automatic arbitrary adjustment, improves the workpiece heating quality and heating repeatability and continuity.

- All solid-state IGBT frequency conversion and power adjustment to achieve automatic frequency tracking.

- Overvoltage, over current, overheating, lack of phase, water shortage, and other automatic protection functions to ensure the reliability of the medium frequency induction heating equipment.

How to maintain an induction heating generator?

- Medium frequency induction heating generator preparation before starting the machine: A series of inspections are needed before the induction heater is turned on each time, including electrical equipment, waterways, etc. Check whether the waterway is blocked, and ensure whether the waterway of the inductor, transformer, and main control cabinet is unblocked. Check the circuit for screw loosening, ignition, and other faults. Medium frequency induction heating equipment is forbidden to turn on when an inductor short circuit occurs and should follow the safety rules of the equipment.

- Medium frequency induction heating generator using environment: Medium frequency induction heating generator is using low voltage and high current to heat the workpiece, so the machine room should be selected in a well-ventilated place, and the room should be kept dry always.

- Medium frequency induction heating generator operator requirements: There should be at least 2 people on duty in the operation room of the medium frequency induction heater, and the relevant personnel with the operation experience of the medium frequency induction heating generator should strictly abide by the safety operation specifications.