What’s medium frequency induction melting furnace?

Medium frequency induction melting furnace is used in heating melting of steel, stainless steel, copper, aluminum, gold, silver, and other metal materials; Smelting capacity from 3KG to 500KG.

What is the structure of medium frequency induction melting furnace?

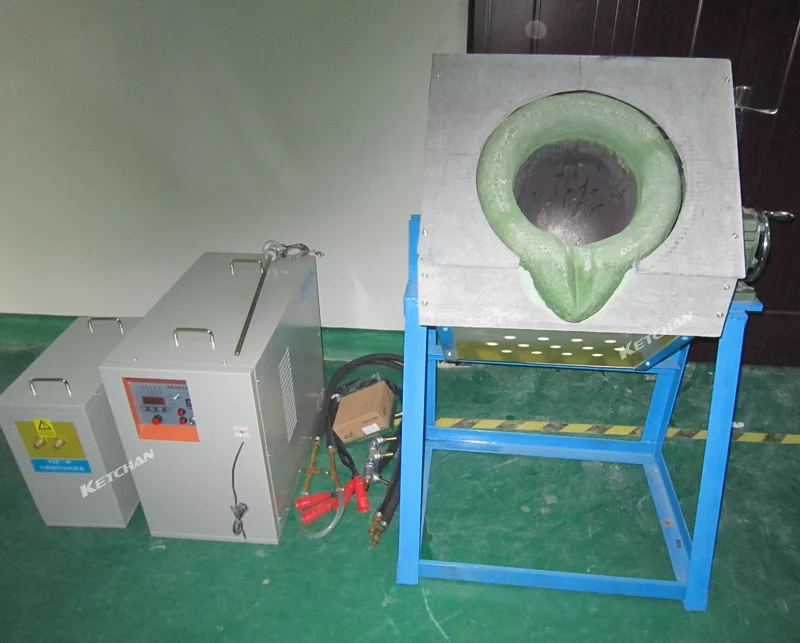

Medium frequency induction melting furnace is including intermediate frequency induction melting power supply, compensation capacitor box and melting furnace, etc. According to different melting application requirements, it may also include an infrared thermometer, temperature controller, and other devices; There are three types of melting furnaces: inverted melting furnaces, top out melting furnaces, and fixed melting furnaces. Tipping type melting furnace can be divided into mechanical tipping furnace, electric tipping furnace, and hydraulic tipping furnace according to the tipping model.

What are medium frequency induction melting furnace advantages?

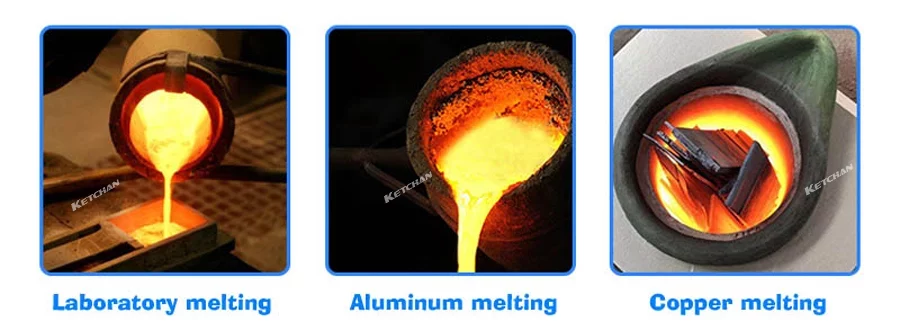

- Medium frequency induction melting furnace is mainly used for steel, stainless steel, copper, aluminum, gold, silver, and other materials induction melting.

- Medium frequency induction smelting has a good electromagnetic stirring effect, which is conducive to melting metal temperature and uniformity of organization, conducive to scum, reduces impurities;

- The medium frequency melting furnace range is wide, from 1KHZ to 20KHZ. It can design an induction coil and match compensation capacitor to determine the size of output frequency by taking into account factors such as melting capacity, electromagnetic stirring, heating efficiency, and noise at work.

- Compared with SCR medium frequency machine, It can energy-saving up to 20%.

- The medium frequency induction melting equipment is small in size, light in weight, melting capacity from a few kilograms to several hundred kilograms, and can choose from a large range, not only suitable for factory production and use but also suitable for schools and research institutes of the small amount of smelting.

Medium frequency induction melting furnace applications

How to choose the suitable medium frequency induction melting furnace?

The maximum heating capacity of each medium-frequency induction melting furnace is listed in the following table. The melting time of each furnace is 50–60 minutes in the cold furnace and 20–30 minutes in a hot furnace.

| Model | Input Power | Melting Capacity of Steel, stainless steel | Melting Capacity of brass,copper,silver,gold | Melting Capacity of aluminum, aluminum alloy |

|---|---|---|---|---|

| KQZ-15 | 15KW | 3KG | 10KG | 3KG |

| KQZ-25 | 25KW | 5KG | 20KG | 5KG |

| KQZ-35 | 35KW | 10KG | 30KG | 10KG |

| KQZ-45 | 45KW | 18KG | 50KG | 18KG |

| KQZ-70 | 70KW | 25KG | 100KG | 25KG |

| KQZ-90 | 90KW | 40KG | 120KG | 40KG |

| KQZ-110 | 110KW | 50KG | 150KG | 50KG |

| KQZ-160 | 160KW | 100KG | 250KG | 100KG |

| KQZ-240 | 250KW | 150KG | 400KG | 150KG |

| KQZ-300 | 300KW | 200KG | 500KG | 200KG |

| KQZ-600 | 600KW | 500KG | 1000KG | 500KG |

Why choose ZHENGZHOU KETCHAN's melting furnace?

- Medium frequency induction melting furnace model choice

After we receive your inquiry, our sales engineer will follow up with you step by step, you can list all your heating parts details and also technical requests, and we will try to find the most suitable and commercial induction melting technical proposal for you. Can do free samples tests and customize induction heating coils.

- Sales price advantage:

We are an end manufacturer, no No middleman sales make a price difference. And also we can guarantee a faster and timely delivery time.

- Installation and training:

We provide free technical guidance and training after-sales. And will also provide the full pipelines and connection drawings, and videos pictures during the Covid period to help each of our users will use our machines.

- After-sales service:

Our warranty period is 12 months, after the warranty period, we will provide the spare parts will basic costs and we have enough spare parts stocks to ensure a timely supply chain.