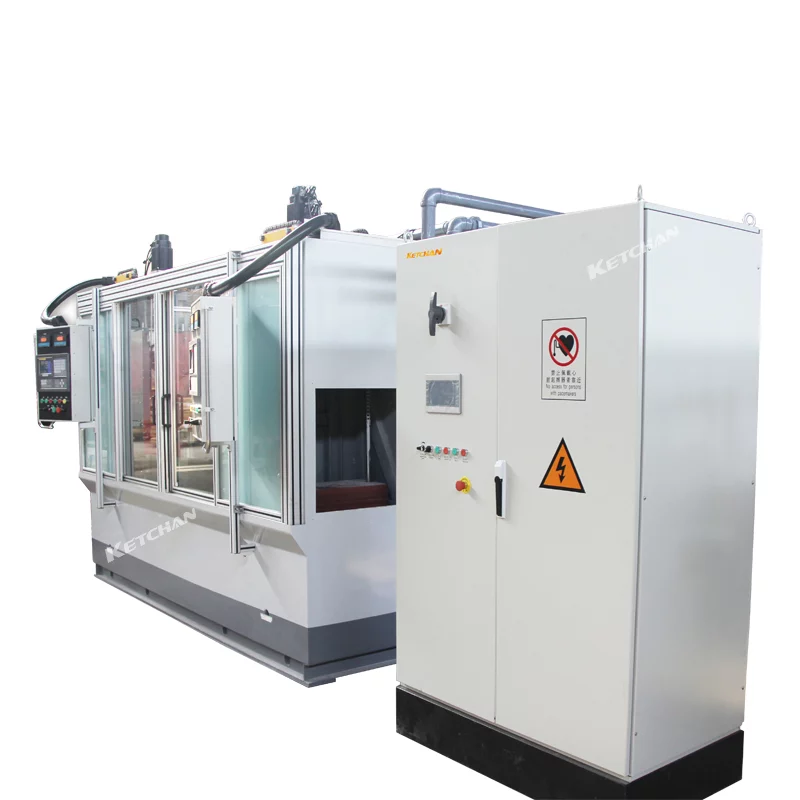

What is outer race induction hardening machine?

Bell shell outer race/wheel bearing induction hardening /tempering equipment is suitable for induction quenching of multi-variety and multi-specification constant velocity universal joint bell shell parts/automobile hub bearing parts. The outer race induction hardening machine tool adopts the intelligent numerical control system centralized control. The workpiece movement/turnover during loading and unloading and processing is all completed by the manipulator. The station rotation is automatically completed by the turntable. This outer race induction hardening equipment is equipped with two quenching stations and one tempering station.At the same time, complete different parts induction quenching and tempering processes. The induction heating power supply adopts the world’s leading transistor solid-state DSP induction heating power supply, full digital control technology, perfect protection function and digital parameter setting and display interface. The dedicated process parameter management and monitoring system can record various data of the monitoring equipment in real time, and has the historical data query function. The bell shell outer race/hub bearing induction quenching/tempering equipment has a high degree of overall intelligence and high processing efficiency.

What is outer race induction hardening machine applications?

Our outer race induction hardening machine is an integrated induction heat treating system widely used for all kinds of automobile parts induction hardening tempering process, like gear, camshaft, drive shaft, crankshaft, torsion bar, coupling, rocker, drill, chain, lifting arm, clutch, brake disc, steering rack, constant speed universal joint, three-column trough shell, shock absorber, bell shell, control rod, shaft sleeve, output shaft, CVJ, TVJ, and CV parts induction heat treating jobs.

What is outer race induction hardening machine features?

- Transmission part: Precision ball screw.

- Hardening load: with multi-ratio induction hardening transformer.

- The CNC induction hardening machine tool guide rail: linear guides.

- Induction coil positioning motor: AC servo motor.

- Two-dimensional movement of the induction coil: Servo motor drive.

- Outer race induction hardening machine hardening method: Partial overall induction quenching/continuous scan quenching; Spraying liquid cooling.

- Protection: water pressure protection, flow protection, air pressure protection, photoelectric safety protection.

- Alarm: sound/light fault alarm, control interface display alarm, and record.

- Inductor and sprinkler cooling interface: stainless steel/brass quick change connector; Water and electricity quick exchange structure.

- Electric control system: touch screen +PLC/828D/840DSL.

- Working stations: 8 stations.

- Cooling method: Closed air-cooled circulation system/industrial refrigeration unit + internal circulation cooling system.

- Process parameter monitoring system: All processing parameters of the outer race induction hardening equipment (power, time, quenching fluid flow, quenching speed, quenching fluid temperature, etc.) can be input or displayed through the dedicated parameter screen, and can be stored. It has the functions of recording, querying, and printing processing parameters.

How to do outer race induction hardening process?

The constant velocity joint is abbreviated as CVJ, it is an important part of the car that transmits torque to the tires. It consists of a sliding universal joint at the end of the transmission shaft, a fixed universal joint at the tire end, and a drive shaft in the middle. Among these workpieces, mainly the bell shell outer race, inner race, and the sliding sleeve need to be induction hardened by a high frequency induction hardening machine. The bell shell induction hardening part is the spline parts and inner ball raceway. The sliding sleeve induction hardening part is the spline part and the three pairs of raceway grooves.

Due to the bell shell outer race spine part deep hardening layer, the spline part hardening machine frequency range is mostly 8-10kHz. According to the workpiece, size details can choose the induction heating machine power supply power 100-300KW. Since the rod, the fillet of the step shaft, and the step surface all need to be hardened, and the hardened layer is required to be continuous, basically, all of them are heated at one time. The inductor must ensure that all parts can be hardened, especially the rounded corners must reach a certain depth. Therefore, the structure is more complex, the step surface is wide, and the effective circle is often composed of multiple sections. After the high-frequency induction quenching machine is quenched, the cooling method is generally carried out by the liquid sprayer. Some workpieces are heated and lowered, and cooled by the plane liquid sprayer on the two sides of the machine tool, or directly in the front and rear liquid sprayers of the inductor device. cooling, etc. The workpiece must rotate as the spline heats and cools.

The bell shell, hub bearing, outer race, and inner race induction hardening process normally is done by the high frequency induction hardening coils, the effective induction coil is inlaid with a magnetic conductor to improve the heating efficiency. There are two types, they are single-turn and multi-turn structures.

The hardened part of the sliding sleeve raceway groove is mainly three pairs of raceway grooves. The raceway groove requires to wear resistance. In the automatic line, induction hardening of high frequency outer race induction hardening machine is also generally used; The parts produced by the special machine are generally heated by a furnace. After low temperature heating, they can meet the requirements of 56-62HRC or ≥55HRC. The hardness of the inner raceway can be tested with an inner hole hardness tester.