What is KETCHAN pipe induction brazing machine?

Zhengzhou KETCHAN is a high-tech enterprise, that specialized in manufacturing and sales of medium frequency, high frequency and ultrahigh frequency induction heating machines power range from 5KW-1000KW,frequency range is 1KHZ~1Mhz. And mostly the pipe induction brazing machine is used for induction brazing copper pipes to pipes, aluminum tubes to tubes, steel tubes to tubes, etc. All of the induction brazing heaters are with Siemens IGBT as the main power components. We are a factory that can provide different induction machines with customized service.

What is KETCHAN pipe induction brazing machine advantages?

- The oxidation rate of the pipe induction brazing machine blank is only 0.3%~1%, while the burning loss rate of the flame furnace is 3%.

- Induction heating equipment with less heat dissipation, little flue gas dust, and workshop temperature is relatively small, can improve the workshop environment and working conditions.

- The heating speed is fast, which can double the productivity of the induction heating machine, reduce the cost and improve the molds service life.

- Short heating time and high efficiency. The productivity of induction heating furnace equipment can reach 80%~90%, while flame furnaces only about 20%, resistance furnace only about 40%.

- Convenient for computer operation, easy to complete the modern management model.

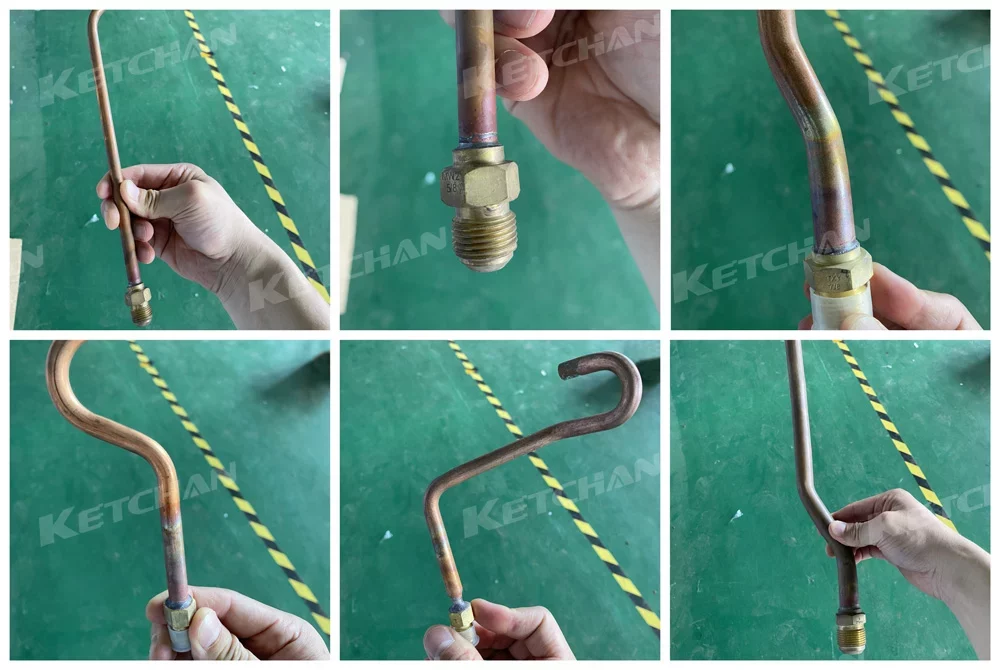

- The induction brazing coil can be customized to match all kinds of different parts of induction heating brazing.

- Adopt the low loss IGBT inverter control technology, the complete induction machine efficiency is more than 95%, also saving the water and power.

What is KETCHAN pipe induction brazing machine applications?

Our pipe induction brazing machines are widely used in the following fields.

- Hardware and plastic: lighting accessories, precision mold accessories, hardware handle, egg beater, drill, alloy steel and steel, steel and copper, copper and copper equivalent metal or dissimilar metal induction welding.

- Tool industry: diamond tool, carbide turning tool, tungsten steel tool, milling cutter, reamer, planer, and other parts induction braze welding;

- Home appliance industry: Induction brazing welding of composite pot bottom, electric kettle, coffee pot heating plate, induction brazing stainless steel flat bottom and aluminum sheet and various shapes electric heating tubes;

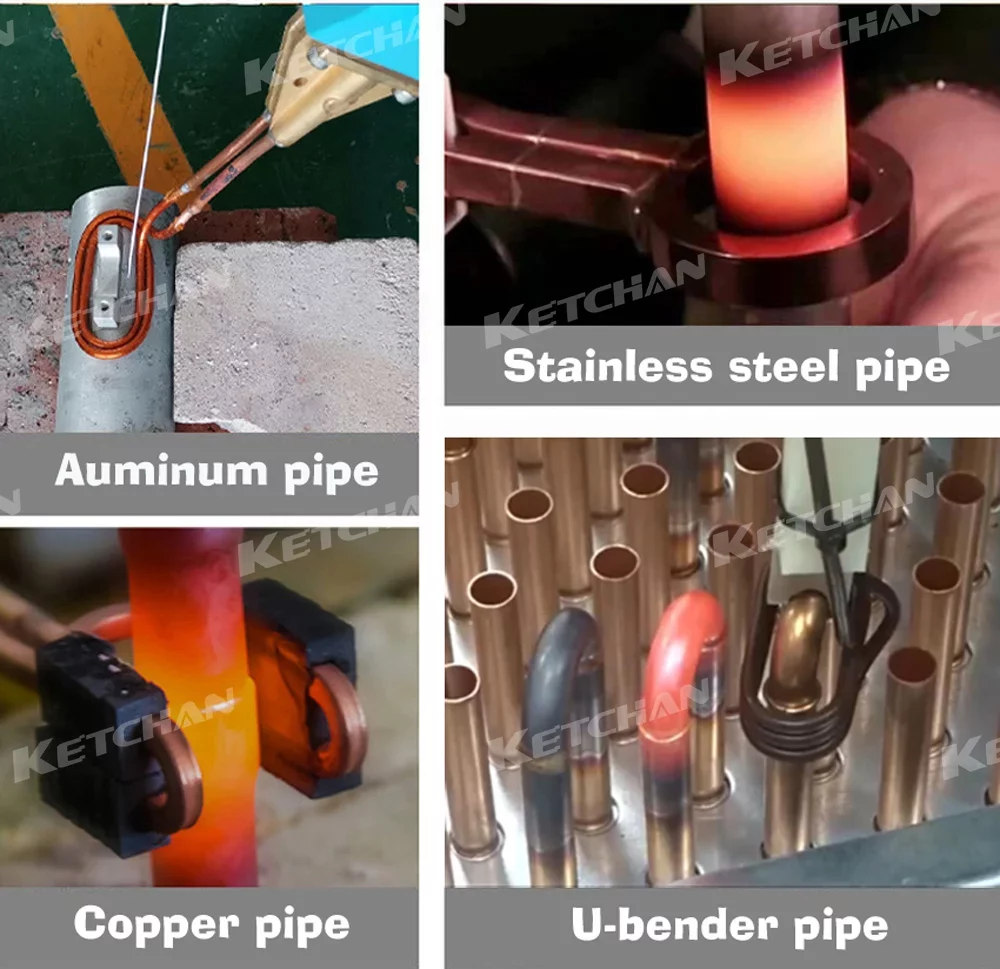

- Plumbing industry: faucet, water pipe joint welding;

- Refrigeration industry: Induction brazing welding of air conditioning shunt, air conditioning liquid mirror, air conditioning condenser, air conditioning tube, copper tube, and so on;

- Automotive industry: automotive oil pipe joint, brake pad, drive shaft, automobile air conditioning pipe welding, quenching;

- Medical industry: welding of needles, detectors, scalpels, and other medical instruments.

- Stainless steel industry: Induction annealing stainless steel basin, stainless steel pot, stainless steel tube, stainless steel tableware, stainless steel cup, sink, etc.

- Metal workpiece industry: golf ball head, cue, copper lock head, hardware copper accessories, kitchen knife handle, blade, aluminum pot, aluminum bucket, aluminum radiator, and all kinds of aluminum products induction annealing.

- Induction melting: Suitable for: iron, steel, copper, aluminum, zinc, and all kinds of precious metals: gold, silver melting.

- Induction forging: For example: Watch case, table blank, handle, mold accessories, kitchen utensils, handicrafts, standard parts, fasteners, mechanical parts processing, copper locks, rivets, steel bar, drill tool, and other metal parts hot forging;

- For example: Computer radiator copper core and aluminum sheet, horn net embedded welding, steel-plastic tube compound, aluminum foil sealing, motor rotor, electric hot pipe heat sealing, and so on.

How to select suitable pipe induction brazing machine?

| Model | Max. Input Power | Induction Heating Head | Output Frequency | Input Voltage | Memo |

|---|---|---|---|---|---|

| KQG-10 | 10 | Standard induction heaters without flexible cable. Portable induction heater with 3-20m flexible cable. | 20-80KHZ | 220V 50/60HZ 380V 50/60HZ 415V 50/60HZ 440V 50/60HZ 480V 50/60HZ | Different heating material can customize different induction heating coils. |

| KQG-20 | 20 | ||||

| KQG-30 | 30 | ||||

| KQG-40 | 40 | ||||

| KQG-50 | 50 | ||||

| KQG-60 | 60 | ||||

| KQG-80 | 80 | ||||

| KQG-100 | 100 | ||||

| KQG-120 | 120 | ||||

| KQG-150 | 150 | ||||

| KQG-160 | 160 | ||||

| KQG-200 | 200 | ||||

| KQG-250 | 250 | ||||

| KQG-300 | 300 | ||||

| KQG-350 | 350 | ||||

| KQG-400 | 400 |