Why use piston rod induction hardening machine?

The piston rod is a connecting part that supports the piston to do work. Most of the applications are in the oil cylinder, and cylinder movement execution parts. It is a moving part with frequent movement and high technical requirements. The piston rod is subjected to a great deal of friction during its operation. Therefore, we commonly use a piston rod induction hardening machine to do the piston rod induction heat treatment process, so that to improve the piston rod service life.

After the piston rod induction hardening machine heat treatment process, the piston rod surface will have the requested hardening depth and hardness, sometimes maybe also need the piston rod induction tempering process, so as to meet the piston rod working requests.

According to piston rod different heat treatment requests, choose the related piston rod induction hardening tempering machine power and frequency ranges.

What is a piston rod induction hardening machine?

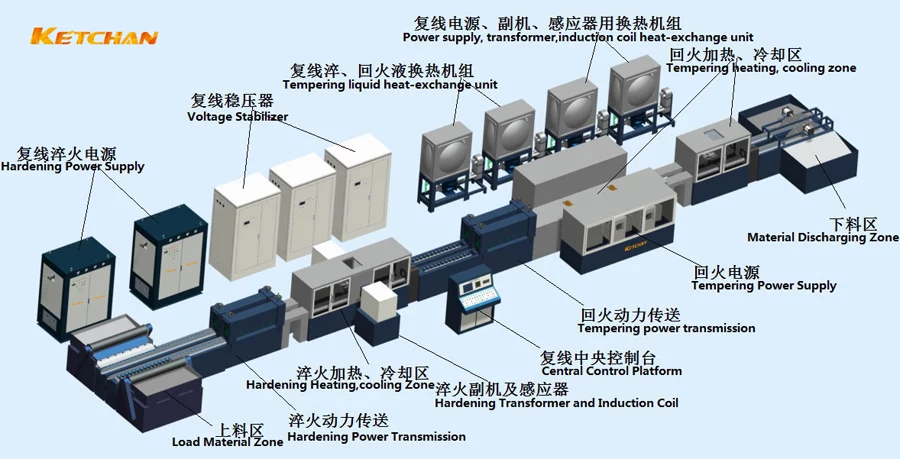

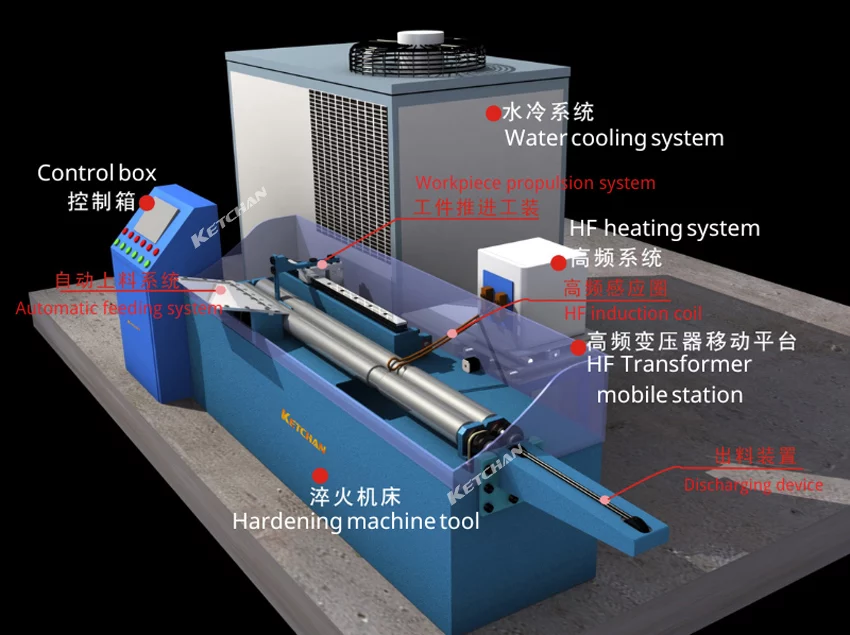

The complete piston rod induction hardening tempering system includes the induction heating power supply, CNC induction hardening tempering machine tool, closed-loop water cooling system, and induction heating coils. The surface of the piston rod can be quenched and heat treated. It can also be used in the production line with other equipment. The induction quenching tempering effect is quite good.

During the real production period, according to different working conditions, can customize horizontal type induction hardening machines and also the vertical type piston rod induction hardening machines.

KQHG0500(S) Vertical Double Position CNC Hardening Machine | Maximum skid stroke | 500mm |

Maximum turning diameter of the workpiece | 500mm | |

Maximum weight of hardening parts | 30kg | |

Working position number | 2 | |

Fast forward and fast backward speed of the workpiece | 100mm/s | |

Workpiece moving speed range | 1~30 mm/s | |

Accuracy of workpiece movement and repeated positioning | ≤±0.1mm | |

Spindle rotation speed | 30-150r/min | |

environment temperature | 0~50°C | |

environment humidity | 80%(25°C) | |

Transformer regulating frame | Back and forth adjustment distance

| ±40mm |

Left-right adjustment distance | ±40mm |

What is piston rod induction hardening machine features?

- This piston rod induction hardening machine matches a vertical CNC hardening machine tool, suitable for small and medium-sized piston rod surface induction heating hardening process. It can complete continuous scanning heating, sectional scanning heating, and fixed time and point heating. The workpiece speed is stepless speed regulation, and the workpiece feeding speed is stepless speed regulation and can be very convenient to realize the workpiece’s fast feeding and return. Under the control of a numerical control system, the heated workpiece is fed while being heated, so as to realize the uniform heating temperature of the workpiece and ensure the stability of the hardening quality.

- This machine tool itself has automatic and manual functions.

- The numerical control system of this machine tool is the English version of numerical control, which has comprehensive functions, stable quality, and a low failure rate.

- The main and auxiliary guide rail of this machine tool are selected linear bearing, high precision, small friction, long life, chrome plated surface, corrosion resistance.The driving parts are ball screw, high speed, wear resistance, excellent performance, and reliable quality.

- The machine is fully closed structure when it works. The metal plate of the splashing part is made of stainless steel. Electric control cabinet and machine tool integrated design, beautiful appearance and convenient operation.

- The machine tool is equipped with a counterweight balancing mechanism and the ball screw bearing is balanced, which improves the running speed and extends the service life.

- The machine is equipped with a 2-D electric transformer adjustment frame, which adopts the latest design. The front, rear, left and right are for electric adjustment. It can be manually operated freely in the operation panel, which is convenient and practical.

- Equipped with special workpiece clamping and positioning fixture tool.

How to select the suitable piston rod induction hardening machine?

- Piston rod induction hardening tempering machine power frequency choice: You can please send your piston rod drawings along with hardening technical requests on. According to the piston rod size, we suggest the suitable power level, and as per the hardening depth and hardness, we suggest the suitable frequency levels.

- CNC induction hardening tempering machine tool part: According to your year’s production volume, we can customize vertical piston rod hardening machine tools and horizontal piston rod induction hardening tempering machines.

- Induction hardening coils and water spraying coil: different piston rod sizes match different induction hardening coils.

- We have served many piston rod manufacturers and have many videos and pictures are expecting to share with you.