What is plasma nitriding furnace structure?

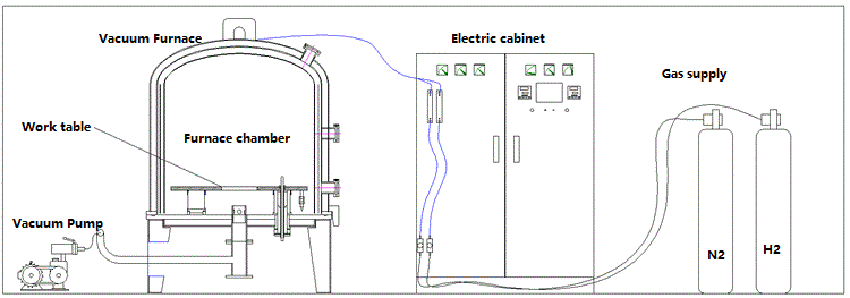

The complete plasma nitriding furnace is consist of the following parts:

- Vacuum furnace body

- Electrical cabinet

- Vacuum acquisition and conditioning system

- Air supply regulation system

What is the difference between gas nitriding furnace and plasma nitriding furnace?

As an effective steel and alloy surface strengthening technology, an ion nitriding furnace has been widely used in the industrial field. It has many advantages such as fast infiltration speed, energy saving, and environmental protection, thereby replacing most gas nitriding. The advantages and disadvantages of both gas nitriding and ion nitriding can be clearly seen in the nitriding process.

- Advantages

- Nitriding gas source: The gas source of ion nitriding can be ammonia, nitrogen, and hydrogen. And gas nitriding can only use ammonia. Nitrogen can be transported and used with restrictions.

- Nitriding speed: Plasma nitriding works under high voltage. The ions are accelerated by the electric field and have great energy, which can easily penetrate into the surface of the workpiece. Gas nitriding side gas infiltrates the work by free diffusion. For the same infiltration layer, the infiltration rate of ion nitriding is more than 3 times that of gas nitriding.

- Exhaust Gas: The exhaust gas discharged from the plasma nitriding furnace includes nitrogen, hydrogen, and water vapor, which are all gases without any odor and pollution. The exhaust gas discharged from the gas nitriding furnace includes nitrogen, hydrogen, water vapor, and ammonia. Ammonia is a very pungent gas.

- Nitriding of stainless steel: Ion nitriding can easily handle 304, 310, 316, and other stainless steels. However, if gas nitriding does not add the pre-passivation film process, even if the treatment time is very long, it will not have the effect of nitriding.

- Disadvantages

- The ion nitriding workpiece must be clean before being loaded into the furnace. If it is not clean, the furnace may not be opened. Gas nitriding, the workpiece is not very clean, and there is not much impact.

- Ion nitriding workpiece loading must follow the corresponding rules, while gas nitriding is not very strict.

- Ion nitriding is picky about parts. Not all workpieces can be ion nitrided, such as small workpieces that are not easy to place, large batches of iron pot treatment, craft pot treatment, workpieces with small diameters and deep holes, etc.

- The price of ion nitriding equipment is high, and the price of the same furnace plasma nitriding furnace is more than twice that of gas nitriding equipment.

What is KETCHAN plasma nitriding furnace features?

Our company is one of the earliest domestic manufacturers specializing in the research and production of nitriding equipment and processes. For more than 20 years, our company has successfully carried out extensive cooperation with hundreds of domestic enterprises and has matched with them many high-quality nitriding equipments. The multi-closed-loop pulse ion nitriding furnace controlled by LDMC touch screen PLC produced by our company has the following main characteristics.

- Simple operations

- Each parameter can be controlled independently.

- The equipment has a long service life.

How to select suitable plasma nitriding furnace?

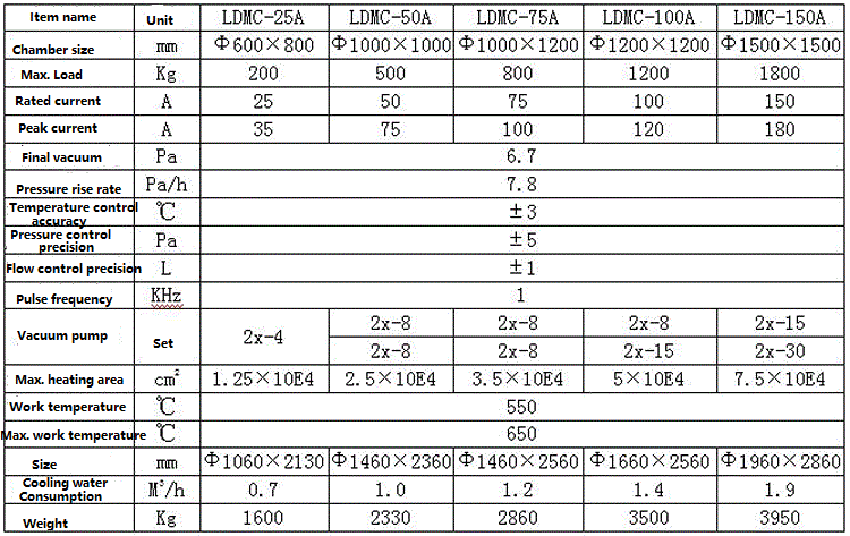

Below is some of our standard plasma nitriding furnace and if you have any other special requests, please contact us for customizing a different one.