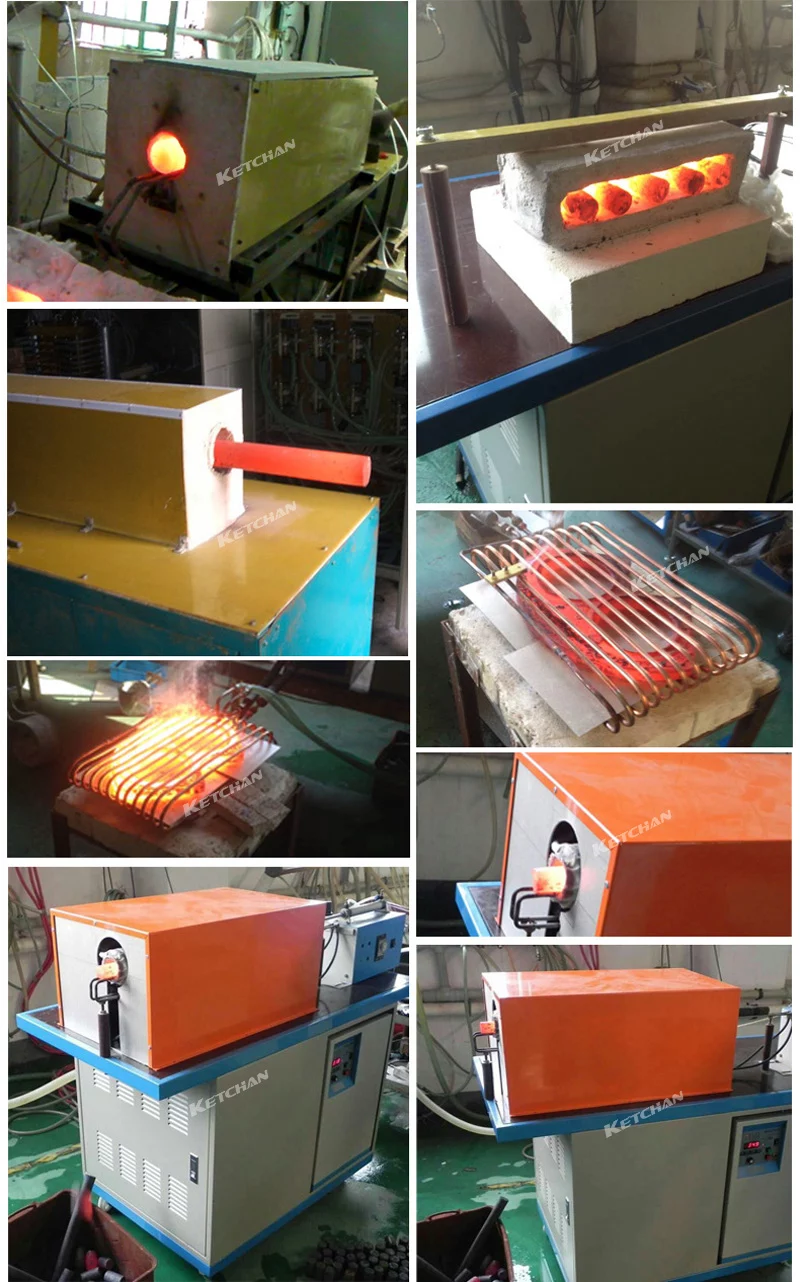

Medium frequency forging furnace structure

KETCHAN medium frequency forging furnace adopt simple induction heating coil, can match automatic feeding forging device, automatic material discharging device and also temperature measurement device to meet all of your billets induction heating forging requirements.

How to choose the suitable medium frequency forging furnace?

Forging model | Heat steel or stainless steel to 1050℃ | Heat copper to 700℃ |

KQZ-35 | 1.25KG/Minute | 1.75KG/Minute |

KQZ-45 | 1.67KG/Minute | 2.33KG/Minute |

KQZ-70 | 2.5KG/Minute | 3.5KG/Minute |

KQZ-90 | 3.33KG/Minute | 4.67KG/Minute |

KQZ-110 | 4.17KG/Minute | 5.83KG/Minute |

KQZ-160 | 5.83KG/Minute | —— |

KQZ-240 | 8.6KG/Minute | —— |

KQZ-300 | 11.25KG/Minute | —— |

KQZ-500 | 17.9KG/Minute | ——– |

The maximum heating capacity of each power model is listed in the table above.

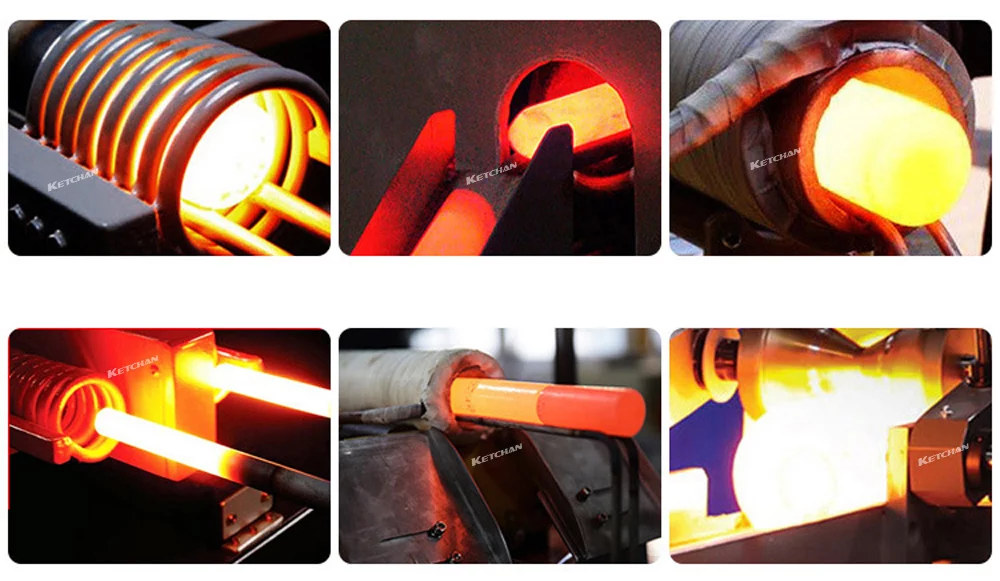

It is mainly used for continuous forging of regular round bar materials and square end materials of steel, iron, aluminum, copper, and other metals with diameters of more than 12mm. It can be used for heating materials as a whole or locally. Customers can select the corresponding medium frequency forging furnace power equipment according to their heating parts weight and speed requests.

Different types of medium frequency forging furnaces differ in size in addition to the intuitive appearance, mainly in heating capacity. The above is the heating capacity of each type of forging furnace. Customers can choose different models of machines according to their heating requirements and with reference to the heating capacity of different models of machines. In order to achieve cheap beauty, cost-saving purposes.

What is KETCHAN medium frequency forging furnace applications?

Our medium frequency forging furnace is mainly used in the standard parts industry, stud head pier thick, nut forming, valve, and lock industry copper hot forming, etc.

KETCHAN medium frequency forging furnace technical features

- Our medium frequency forging furnace with a large frequency range, from 1KHZ to 20KHZ, according to the specific heating workpiece diameter, can choose the appropriate frequency ranges.

- When the whole material is heated in a medium frequency forging furnace, the length of the induction forging furnace is 500mm to 1000mm, and the multiple materials are heated at the same time, which ensures the induction forging effect.

- Medium frequency forging furnace adopts continuous heating method, the internal load is balanced, induction coil, overcome the whole heating process, the single bar load from room temperature to 1100 ℃, the great changes in load and caused great changes of the actual healing power of the equipment, make whole continuous heating process, the real power of the device can ensure the rated output value of more than 85%, The equipment is used efficiently.

- When heating non-ferrous metals such as copper and aluminum, the actual power of the equipment can be more than 85% of the power through the proper design of the induction coil and capacitor, and the heating capacity can reach 3.5kg/ kW h when heating copper.

- Compared with SCR, it is not only small in size, and convenient in maintenance, but also saves 15-20% of electricity.