What’s RF induction heating equipment?

A High-frequency RF induction heating equipment power supply is a kind of induction heating equipment with high efficiency and fast speed for local or overall heating of metal materials. Its main circuit adopts new types high power electronic devices such as IGBT, and MOSFET, fundamentally innovation is characterized by a tube of the old induction heating equipment, which can replace acetylene heating, coal heating oven, box-type electric furnace heating lagging heating means such as induction heat treatment, can greatly improve the quality of products, effective save more than 60% of the electricity, improve working conditions. For the enterprise to a certain extent to save costs, and increase profits.

High frequency RF induction heating equipment power supply, is popular for many reasons, not only lies in its good heating effect, but also in its very wide application. High-frequency RF induction heating equipment power supply can not only heat treat bolts and nuts, bars, rivets, steel plates, steel pipes, and springs, but also annealing and heat treat steel bars, wires, welds, etc., and welding and heat treat turning tools, milling cutters, diamond saw blades, drills, etc.

High frequency RF induction heating equipment heating power supply is simple to operate, that is, learn quickly, no open fire, no high temperature, high voltage (working voltage of induction coil is 36V), with good safety. When the workpiece is heated and induction heat treated, it can be used with a feeding device, sorting device, thermometer, time relay, etc., which can not only ensure the accuracy of heating temperature but also enable workers to realize mechanization and intelligent production and improve production efficiency.

What are RF induction heating equipment advantages?

- The RF induction heating equipment heating temperature is high, the speed is faster, the heating time is short, and the metal material is heated evenly. The surface of the heated material is less oxidation, the workpiece deformation is small, and it is a non-contact heating method.

- Flexible output power adjustment, convenient, accurate control.

- The temperature of the heated workpiece is easily controlled, so the product quality is stable.

- The complex workpiece can be heated by changing the shape of the induction heating coil, and local heating can also be realized.

- Due to the use of its own small loss transistor device and inverter control technology, the efficiency of the whole machine can reach more than 95%, and the effect of energy saving and water saving is remarkable.

- Machine small volume, light weight, good working environment, no noise, and no dust.

- All kinds of protective action sensitive, the main device has a long life, collection of low failure rate, reliable performance, can work continuously.

- The machine connected to water and electricity can work, simple operation, and convenient maintenance.

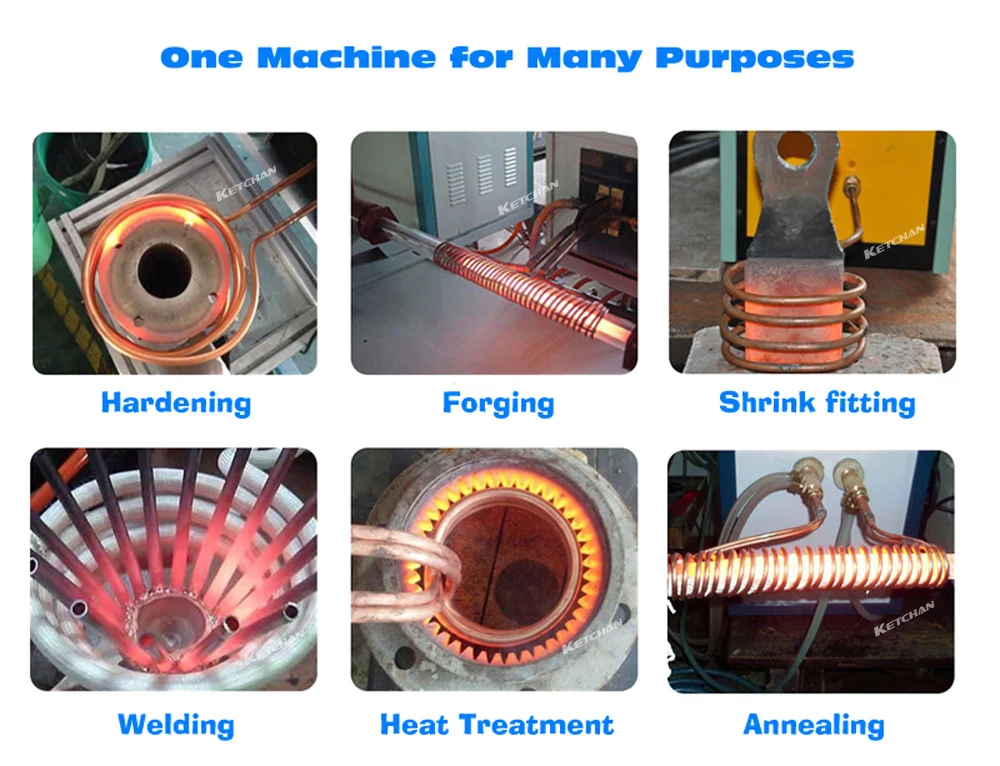

RF Induction Heating Equipment application

Replace different induction coils, transform different heating methods, so that the heating is more widely used.

How to choose suitable RF induction heating equipment?

When doing different workpiece heating jobs, in order to choose the suitable RF induction heating equipment, for different heating applications, we need to know the following technical data to make a suitable induction heating technical proposal for you.

- Induction brazing welding: we need to know the detailed brazed part size, shape, brazing flux material, brazing speed, and brazing temperature details.

- Induction hot forging: Normally according to different induction heating speed requests, choose the related induction forging machines, for bigger induction heating machine power level, the faster heating speed.

- Induction hardening: Combined with different workpiece shapes, hardening methods, hardening hardness, case depth requests, and material details, can choose the suitable induction hardening systems.

- Induction annealing: According to the different workpiece and heating requests choose the different induction annealing systems.

- Induction melting: According to the different melting speeds and melting volume choose the suitable induction melting systems.

Why use Zhengzhou KETCHAN RF induction heating equipment?

- We are a direct RF induction heating equipment manufacturer in China for more than 20 years.

- Professional R&D team: We have a professional R&D technical team, we can provide the faster induction heating machine technical proposal for each of our users in 24 hours and we have many induction heating patents.

- Customize professional technical solutions: According to different customers’ technical requests, we can customize related induction heating technical solutions.

- Modern production workshop: we have our own induction heating production buildings with modern management systems.

- After sales service: All of KETCHAN RF induction heating equipment’s warranty period is 12 months, we provide oveseas on-site service.