What is shaft induction hardening machine?

The industry shaft induction hardening machine generally refers to the shaft surface local induction hardening process, the material is 45 steel or 40Cr, and the quenching hardness can be set according to the heating parts diameter, induction current, and heating time. The depth of the hardened layer depends on the frequency of the induction hardening equipment and also the heating time. The higher frequency or the shorter the heating time, the lower the hardening layer depth.

In the actual production process, there are often hardness requirements for the shaft core, and it is generally required to go to professional induction heat treatment manufacturers factory to do the heat treatment jobs, this brings the disadvantages of long processing cycle and high cost. If shaft induction quenching is used to make the center of the shaft meet the specified hardness requirements, it is required that the heating depth of induction equipment must reach the center of the shaft, and the temperature of the center must reach above the critical temperature.

What is shaft induction hardening machine's advantages?

- Meet all kinds of the shaft, gear, sprocket, disk quenching heat treatment requirements, mature process, quality assurance, electricity safety, and stability

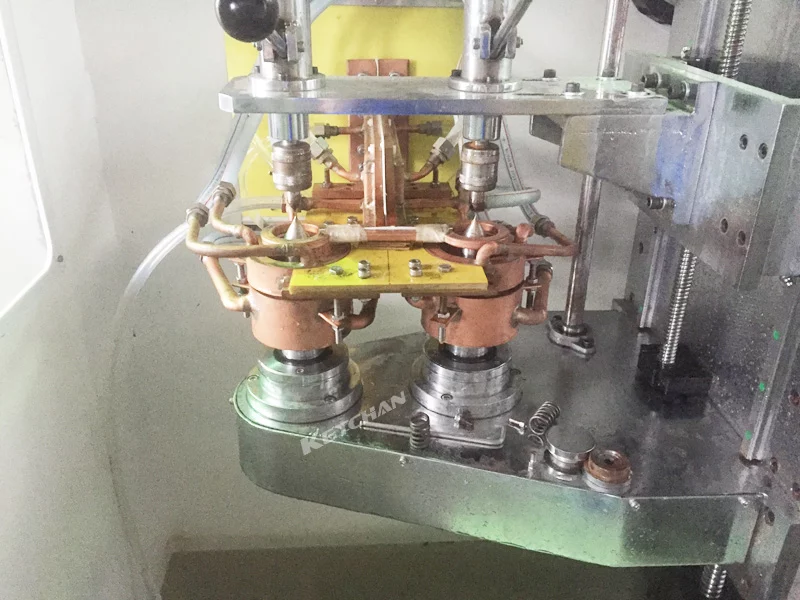

- The induction hardening coil adopts an imitation inductor, scanning quenching while spraying water, the hardness, and depth of the quenching layer can meet the requirements.

- Shaft induction hardening machine is suitable for all kinds of different shafts hardening tempering jobs.

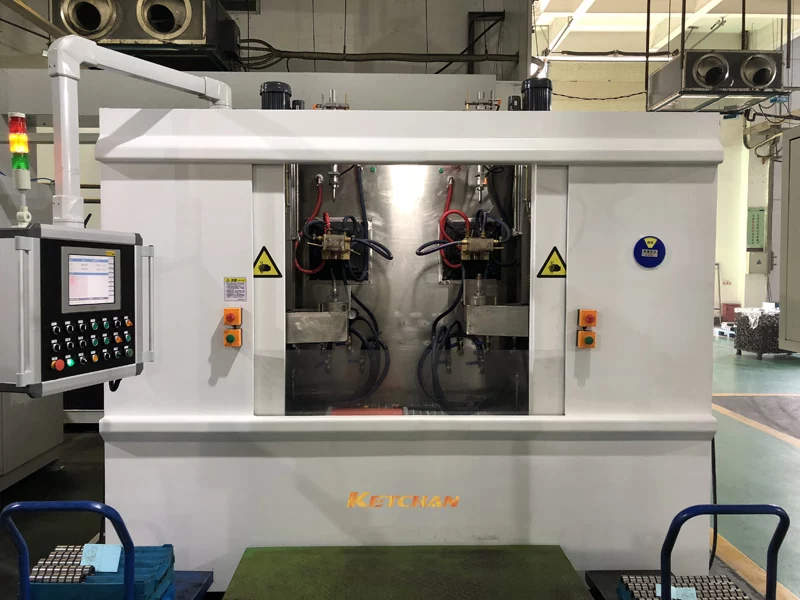

- CNC machine tool body part: the machine tool adopts a welding bed structure and conducts stress relief annealing as a whole. The surface of the main exposed parts is specially treated with good rust and corrosion resistance.

- Top tip adjusting mechanism: the top tip adjusting adopts electric adjustment, which can realize the different workpiece length clamping.

- Working table system: the stepping motor is used to drive the ball screw through the variable speed mechanism to realize the lifting movement of the upper table, the moving speed is stepless adjustable, the transmission is light, and the guiding accuracy is high, the positioning is accurate.

- Spindle rotation system: the spindle rotation is driven by the asynchronous motor through the variable speed mechanism and the drive shaft. Using frequency conversion speed regulation to achieve stepless speed adjustment of parts.

- Cover frame: Cover frame is made of a thick steel plate. Excellent production, beautiful appearance, generous color. The upper part of the cover frame is provided with a glass window and sliding door, which can not only prevent the splashing of cooling water but also facilitate the loading and unloading of parts and monitor the induction quenching process.

- Electrical control part: The electrical control part is composed of the numerical control system, frequency conversion governor, intermediate relay, and so on. Can store more than 20 kinds of parts induction quenching process, through the NUMERICAL control keyboard can be programmed to store a variety of programs.

How to select the suitable shaft induction hardening machine?

When doing the different diameter shafts induction hardening process should choose a different frequency shaft induction hardening machine. Generally can refer to the following frequency choice principles:

- Shaft diameter in the range of 3.5~10mm, suitable for frequency 250KHZ ultra high frequency induction quenching equipment;

- Shaft diameter in the range of 8~18mm, suitable for high-frequency induction quenching equipment with a frequency of 70KHZ;

- Shaft diameter in the range of 10~28mm, suitable for frequency 35KHZ ultra audio induction hardening equipment;

- Shaft diameter in the range of 30~100mm, suitable for 2.5~8KHZ medium frequency shaft induction hardening machine.

- Shaft diameter of 100mm or more, suitable for 1KHZ induction quenching equipment;

- According to the actual requirements of the hardened layer depth of shaft parts, the calculation can also be determined.

What are the shaft induction hardening applications?

- Hardware tools, hand tools camshaft high-frequency quenching machine. Such as pliers, wrenches, spanners, hammers, axes, etc…

- High-frequency induction hardening machine for camshaft of auto parts and motorcycle parts. Such as crankshaft, connecting rod, piston pin, crank pin, sprocket, camshaft, valve, all kinds of rocker’s arm, rocker arm shaft; Transmission box gear, spline shaft, half shaft, all kinds of small shaft, all kinds of fork and other high-frequency induction heat treatment equipment.

- Power tools on the gear, shaft, etc., camshaft induction hardening machine.

- Hydraulic components, pneumatic components, camshaft high-frequency quenching machine. Such as the plunger pump column.

- All kinds of valves on the reversing shaft, gear pump, gear, camshaft induction hardening machine.

- Heat treatment of metal parts. Such as all kinds of gear, sprockets, all kinds of shafts, spline shafts, pins, shaft camshafts high-frequency quenching machines.