What is solid state induction heating machine?

All-solid-state induction heating machine refers to the induction heating power supply of various power transistors, such as MOSFET, IGBT, and other power devices, also called modern induction heating power supply. “Solid state” induction heating power supply is for thyristor and vacuum tube induction heating power supply. It has the advantages of a small induction machine power supply, low loss, high inverter conversion efficiency, easy operation and control, and good safety.

What is solid station induction heating machine advantage?

- The basic theory of the circuit has not changed much, because of the use of new power devices, the circuit and the implementation of technology have a great development;

- In power rectifier and inverter circuit, module devices are used to replace single power devices. In order to achieve greater power, solid station induction heating machine power devices are used in series or parallel.

- The control circuit and protection circuit adopt a digital integrated circuit and special-purpose integrated circuit, which simplifies the circuit design and improves the reliability of the complete induction heating system.

- New circuit components, such as non-inductive capacitor module, non-inductive resistance, power ferrite application, etc.

- The frequency range is wide, ranging from 0.1 to 500kHz, covering the range of medium frequency, high frequency, and super audio solid state induction heating machine.

- High conversion efficiency and obvious energy saving.

- The whole unit is compact and can save 66% to 84% space compared with the valve equipment.

- Perfect protection circuit, high reliability;

- Inside the power supply, no high voltage at the output end, and high security.

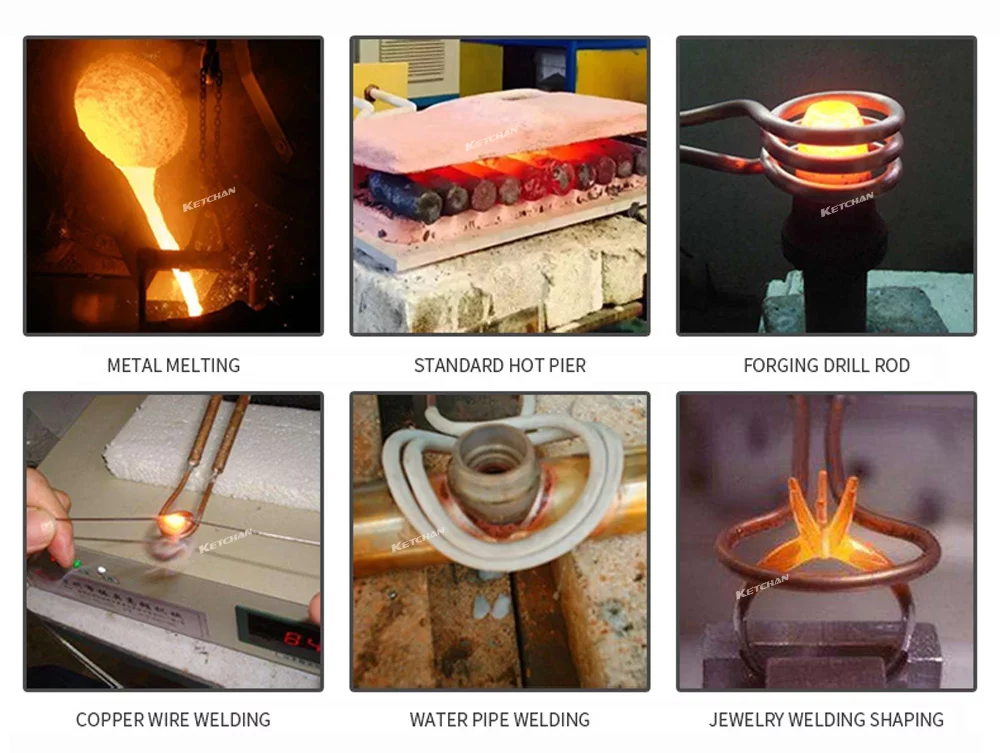

What are solid state induction heating machine applications?

- Induction Brazing: Induction brazing welding cutting tools, drilling tools, cutting tools, woodworking tools, turning tools, brazing bits, brazing reamer, cutter, drill bit, saw blade serrate, glasses frame, steel pipe, copper pipe welding, same of dissimilar metal welding, compressor, pressure gauge, stainless steel pot, relay contact composite materials with different welding transformer winding copper wire welding, storage (gas filling mouth of welding, the welding of stainless steel meals, kitchen utensils and appliances).

- Induction heat treating: Gear, machine tool guide rail, hardware tools, pneumatic tools, power tools, hydraulic parts, ductile iron, auto parts, internal parts, and other mechanical metal parts (surface, inner hole, local, integral) induction quenching, induction annealing, stainless steel pot products stretching.

- Induction hot forging: Standard parts, fasteners, master pieces, small hardware, straight shank twist drill, overall, local heating and twist drill of hot upsetting the following round steel, hot-rolled, diameter 100 mm to the annealing of metal, stretching, modeling, embossing, bending, smashing head, wire nail, stainless steel products (wire) heating type annealing, stretching, rise, thermal expansion.

- Other induction heating fields: aluminum plastic tube, steel plastic tube, cable, wire heating coating, metal preheating coating, semiconductor single crystal growth, heat matching, bottle mouth heat sealing, toothpaste skin heat sealing, powder coating, metal implanted plastic, food, beverage, pharmaceutical industry used aluminum foil hot sealing.

How to select a suitable solid state induction heating machine?

Solid state induction heating machines, according to different output frequency levels can be divided into medium frequency, high frequency, and ultrahigh frequency induction heating machines. Also different induction heating process requests also need different frequency ranges. If choosing the wrong frequency level can not meet the induction heating requests, and cause the failed induction heat treating result.

- Induction hot forging: the bigger the workpiece diameter, the lower frequency should be.

- Induction heat treating: the lower the hardening depth, the high the frequency level should be. The bigger the hardening depth, the lower should frequency should be chosen.

- Induction brazing: The larger the brazing area, the lower frequency should be.

- Induction melting: We choose the suitable induction melting furnace as per the production efficiency, smaller volume can choose high frequency induction machine, and bigger volume can choose medium frequency induction machines.