Metal has become one of the indispensable materials in life, and has been widely used in various industries, but we can see products that have only been processed in life, such as copper in wires, pots, screwdrivers, hammers, Aluminum in computer heatsinks, etc.

To make metal becomes what we want, the most important step is to process it, and the most common method for metal processing is to heat it to change its shape, but the traditional method is too slow to heat, and the most popular method at present One method of heating metals is induction heating, and today we want to say our spindle bar induction heating equipment.

But it takes a long time to use the above heating method, and now there is a method that can quickly heat the metal induction heating. Induction heating, also known as electromagnetic induction heating, has been widely used in metal hot casting, smelting, heat treatment, welding preheating, and post-weld heat treatment, and has been well received in the industry due to its high heating efficiency and fast speed.

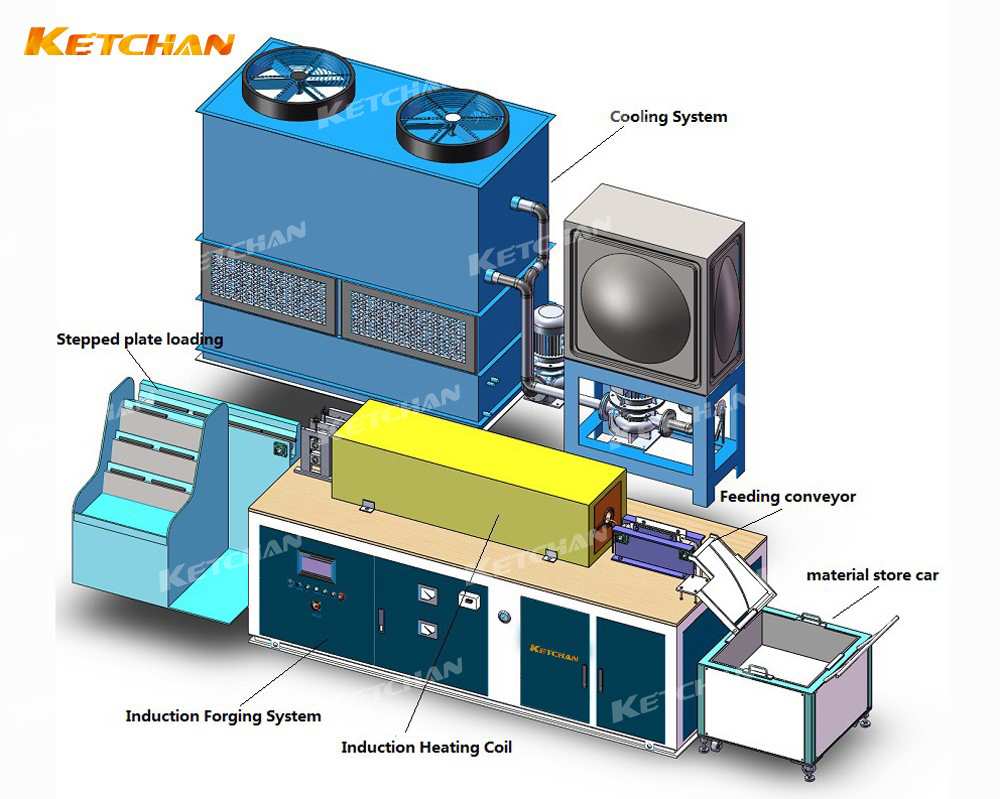

The complete splindle bar induction heating equipment part mainly includes an all-digital induction heating power supply and diathermy furnace; the electrical control and protection part uses PLC and a touch screen to realize the control and protection of the whole system; the mechanical part mainly includes the workpiece feeding and ejecting mechanism; temperature control The part mainly cooperates with the induction heating power supply to control the temperature of the workpiece in a closed loop to ensure the accuracy and consistency of temperature control; the cooling part is mainly used to cool the power supply and the induction coil in the forging furnace to ensure the normal operation of the equipment.

Especially in induction melting, Zhengzhou Ketchan has a special R&D team. The newly developed intermediate frequency induction heating furnace equipment mainly conducts induction heating for ingots and bars and is equipped with a complete set of automatic heating equipment, including induction heating part, electrical control, protection part, mechanical part, temperature control part, and cooling part.

Some induction melting applications actually done

Relate Products

-

Induction Heat Treatment system

Solid State Induction Heating Machine

-

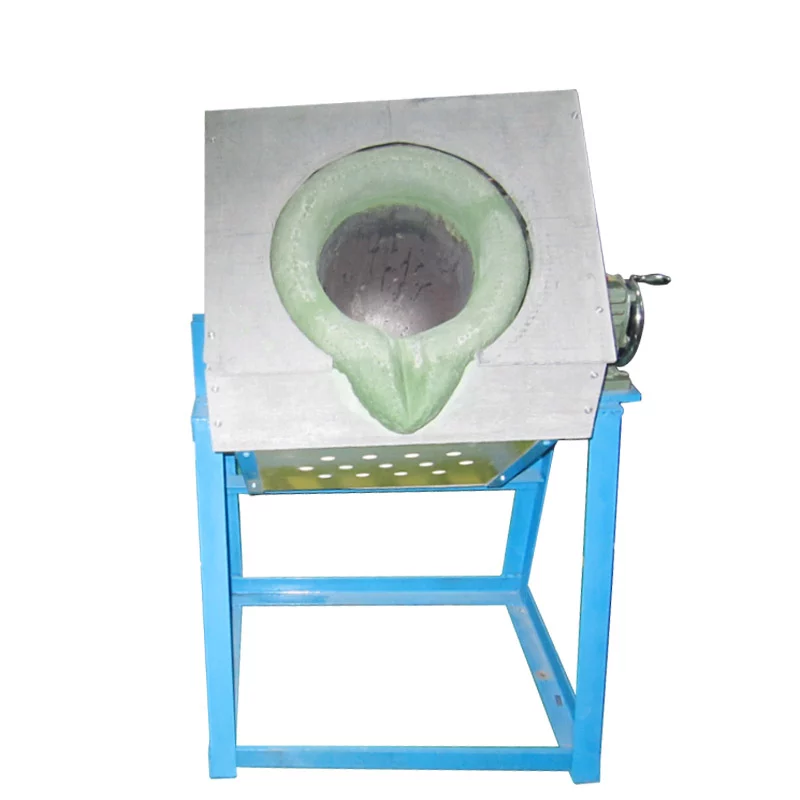

Induction Melting System

IGBT Induction Melting Furnace

-

Induction Melting System

Metal Induction Melting Furnace

-

Induction Melting System

Metal Smelting furnace

-

Induction Forging System

Induction Forging Machine

-

Induction Forging System

Billet Induction Forging Furnace