What is steel shell melting furnace?

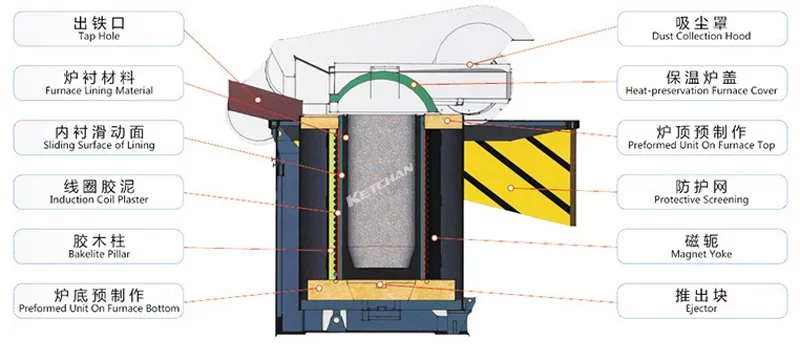

The new steel shell melting furnace adopts steel frame structure, which is composed of a furnace fixed frame and furnace body, and the furnace fixed frame and furnace body adopt an integral skeleton structure. The tilting position of the furnace body is controlled by a hydraulic system, which is realized by two hydraulic cylinders on both sides of the furnace body. Coil height, diameter ratio is appropriate, high power factor, high electrical efficiency.

What is the steel shell melting furnace working principle?

The intermediate frequency steel shell melting furnace adopts the basic principle of induction heating, “induction heating” is the method of electromagnetic induction to generate induction current in the load itself to heat the load. The law of electromagnetic induction e=W* -D φ /dt is also used.

What is the structure of steel shell melting furnace?

ZHENGZHOU KETCHAN medium frequency steel shell melting furnace is composed of a medium frequency power supply cabinet, compensation capacitor bank, steel shell furnace body, magnetic yoke and water cooling cable, hydraulic station, tilting furnace control box, and so on.

What is the steel shell melting furnace applications?

Steel shell melting furnace is mainly used in smelting steel, iron, copper, aluminum, and alloy, with high melting efficiency, good electricity saving effect, uniform metal composition, less burning loss, rapid temperature rise, easy temperature control and other characteristics, suitable for various metal induction smelting occasions.

What is the steel shell melting furnace advantages?

- Under normal working conditions, the steel shell melting furnace melt iron, and steel smelting power consumption is each ton 550-600KW.h;

- The power factor of the whole process is maintained above 0.96, without an additional compensation device;

- Effectively control the high harmonic, do not interfere with the surrounding electrical equipment, do not pollute the power grid;

- The frequency range is wide, and the optimal resonance state is always maintained in the melting process.

- Zero-voltage scanning soft start mode, can start or stop at any time in any state, with no impact on the power supply;

- Fast melting, low production cost; Low pollution, in line with national environmental protection requirements;

- A steel shell melting furnace can melt the metal material directly from the cold furnace, the solution can be emptied completely, and it is convenient to replace the melting material.

- Flexible and convenient power adjustment, continuous smooth adjustment; Uniform temperature easy to control, less oxidation burning loss, uniform metal composition;

- The steel shell melting furnace shell adopts steel structure or cast aluminum alloy, which covers a small area. The furnace body is easy to turn over and dump, manual, electric, hydraulic dumping furnace can be selected;

- Leaky furnace alarm device, timely and effective protection of personal and equipment safety;

- Furnace lining ejecting mechanism, replacing furnace lining becomes fast and efficient, improve production efficiency;

- Wide range of frequency adaptation, fast melting, low production cost, uniform temperature easy to control;

- The furnace body is easy to turn over and dump, and the metal composition is uniform.

- Small occupation area, effective treatment of high harmonics;

- The stability of steel shell melting furnace body is good, which is helpful to prolong the life of the furnace lining.

- Low noise, good working environment;

- The role of steel shell melting furnace is firm and not easy to damage, strong safety;

- The unique water-cooled cable connection minimizes the shift of water-cooled cable when tilting the furnace and improves its service life;

- The function of the steel melting furnace cover is to minimize heat loss;

- According to the different requirements of various metal smelting, elaborate design;

- Various specifications of the induction coil, reasonable selection of copper tube wall thickness and specifications, so as to improve the utilization rate of electric energy;

- Strong coil support design eliminates the possibility of short circuit between turns, greatly prolongs the service life of the induction coil;

- The use of high-performance insulating materials;

- The coil is covered with more than 50% magnetic yoke to reduce magnetic leakage;

- Cooling rings are used at the top and bottom to prolong the lining life.

- The inter-turn clearance of the induction coil is convenient for maintenance and conducive to water vapor release;

- To improve the working environment, smoke collecting device can be selected.

How is the steel shell melting furnace working efficiency and loss?

- Heat loss caused by current flow in induction coil: the loss is taken away by cooling water. This part of the loss is the main loss of the system, which is related to inductor structure, physical properties of charge, and heating frequency. The “electric efficiency” is commonly used to describe this loss. Electrical efficiency is the ratio of the energy transmitted to the heated workpiece to the energy the sensor receives from the power source.

- Heat loss of steel shell melting furnace: the loss caused by heat dissipation of the heated workpiece, which is second only to inductor loss. This loss is often described by the term “thermal efficiency”, which is the ratio of the net heat applied to the workpiece to the total heat received from the induction coil.

- The transmission loss of steel shell melting furnace: the loss caused by cable and bus from frequency conversion power supply to load, generally in 2% ~ 7%.

Companion cooling tower for steel shell melting furnace