Summary

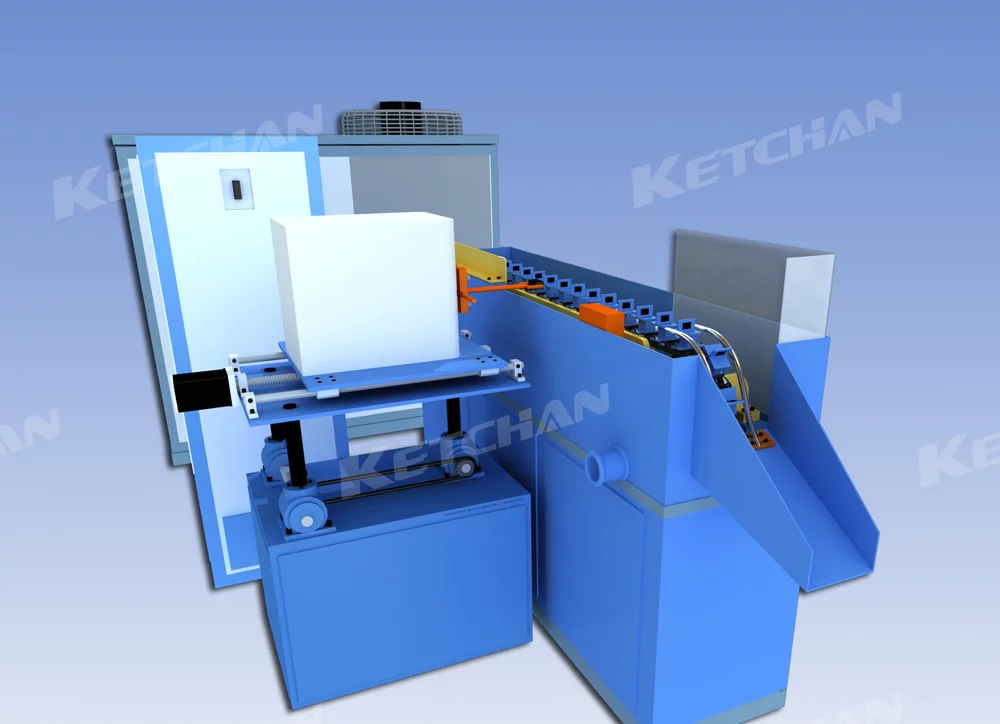

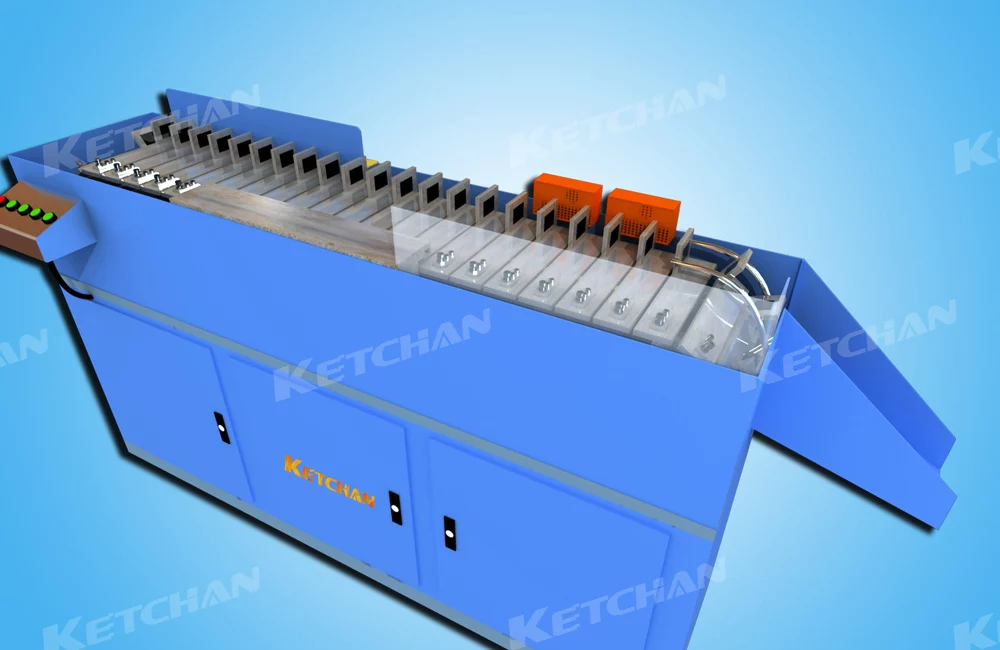

This horizontal hardening machine tool adopts the workpiece horizontal movement method. It can be connected with the upper and lower sequence equipment to conduct the fully automatic production, it can greatly improve production efficiency, save energy, shorten the product processing cycle and reduce logistics costs. The induction coil has Z/Y axis movement functions. The workpiece spindle rotation is equipped with a speed regulating drive mechanism, equipped with a CNC system, continuous scanning quenching, and piecewise scanning quenching of hardened parts can be realized.

It is suitable for all kinds of various shaft parts components continuous scanning and induction heating quenching and subsection scanning and heating quenching. The control system adopts CNC control, it can realize displacement control and power program setting. The feeding mechanism adopts a stepping feeding mode, the pieces do not bump against each other when doing the induction hardening tempering process. Push motor adopts AC servo motor, rotary motor adopts reduction motor, can also add the induction tempering process on this induction heat treatment production lines.

What is horizontal hardening machine tool technical features?

- Humanized design horizontal hardening machine tool.

- High-strength induction welded machine tool body.

- With multi-ratio induction hardening transformer.

- Fully imported ball screw.

- Water pressure and water flow protection of electrical contact.

- Rotary operation box.

- Sound/light breakdown declaration.

- Sound/light fault alarm.

- Water pipelines use the quick joints.

- Machine tool structure: brazing welding.

- Rotary control mode: frequency converter/stepper motor/AC servo motor.

- Electric control: PLC/ touch screen +PLC/808D/828D/840DSL.

- Transformer slide adjustment: Manual/automatic adjustment.

- Push rod moving motor: reduction motor/stepper motor/AC servo motor.

- Push rod moving guide: rectangular linear guide.

- Working stations: 1-2 stations.

What is horizontal hardening machine tool application cases?

This horizontal hardening machine tool can complete the complex workpiece automatic induction hardening process, including mold (bending, stamping, forming, etc.), curved workpiece, shaft, gear, and a variety of special-shaped workpiece, with a high automation and accuracy degree, widely used in boiler manufacturing, auto mold, auto parts, machine tools, and other machinery manufacturing industry.

What is horizontal hardening machine tool technical data?

The horizontal hardening machine tool can do the workpiece diameter of 15~600mm, length is 200~6000mm, and for larger complex heat-treated workpieces, we can customize different induction hardening machine tools.

| Model / Data | KQBY1250 | KQBY1650 | KQBY2050 | KQBY2550 | KQBY3050 | KQBY4050 |

|---|---|---|---|---|---|---|

| Max. Clamp length(mm) | 1250 | 1650 | 2050 | 2550 | 3050 | 4050 |

| Max. Hardening length(mm) | 1200 | 1600 | 2000 | 2500 | 3000 | 4000 |

| Part swing diameter(mm) | 400 | 500 | 500 | 500 | 500 | 600 |

| Part weight(Kg) | 300 | 500 | 1000 | 1500 | 3000 | 5000 |

| Rotation speed(rpm) | 20~150 | 20~150 | 20~150 | 20~150 | 20~150 | 20~150 |

| Moving speed(mm/s) | 20~60 | 20~60 | 20~60 | 20~60 | 20~60 | 20~60 |

| Main spindle number | 1 | 1 | 1 | 1 | 1 | 1 |

Memo: The above horizontal induction hardening machine is just a part of the machine which we have done. Normally most induction hardening system is customized systems. As per different users’ technical requests, we can design and make different application induction hardening systems.

Why we choose Zhengzhou KETCHAN hardening machine tool?

- Our products range:

We are committed to doing the complete induction hardening systems turn-key project, including the following machines:

- Induction heating machine: Power from 5KW-5000KW,frequency range 0.1-500KHZ.

- CNC hardening machine tool: We can customize different CNC hardening machine tools including vertical hardening machine tools and horizontal hardening machine tools for different gears and shafts applications.

- Cooling system: Including the closed-loop water cooling system and industrial chillers for induction machines, induction coils, and hardening medium cooling process.

- Induction coils: This induction coil can be customized for different applications.

- Another optional part: Energy monitoring system, fume purification system, etc.

- Before sales service:

- According to different induction heating parts details, we will do the detailed induction heating technical proposal along with quotations for you.

- If necessary, we can do the induction heat treatment testing for you.

- Give you our full technical guidance about the complete induction hardening technical process.

- After-sales service:

- Warranty period: 1 year.

- We provide all the parts including the connection pipelines, also we can provide overseas technical service.

- We have agents in some countries.

- Provide 24 hours online technical support.

- Spare parts can be delivered in 1-2 days.