What is induction quenching?

The main application of the induction method is to harden steel. An alternating magnetic field is generated with one or more induction coils. The magnetic field creates eddy currents in the metal and heats the workpiece to the desired temperature. The heated workpiece is quenched with water, oil, or emulsion immediately after the induction heating. This cools the metal until the martensitic transformation occurs, creating a hardened surface that is harder than the base metal.

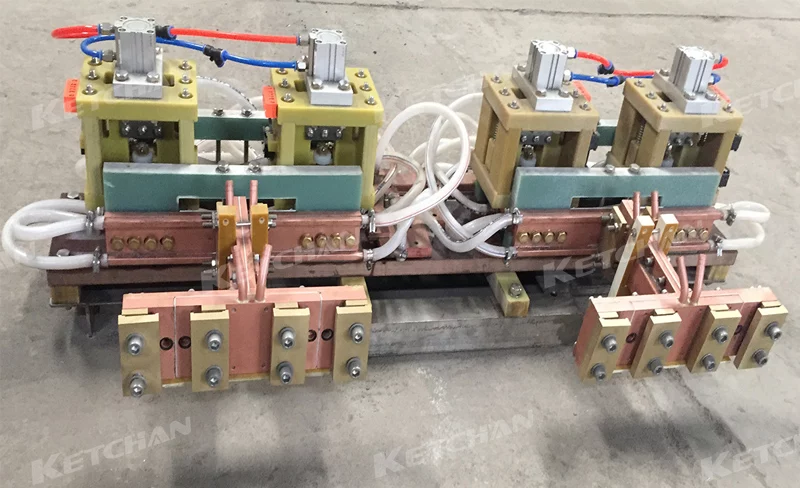

In order to meet different users’ different workpiece induction heat treatment jobs, we can customize different induction quenching systems to meet your quenching requests.

What is the induction quenching advantages?

- The heat source is on the surface of the workpiece, the heating speed is fast, and the thermal efficiency is higher.

- Because the workpiece is not heated as a whole, the deformation is small.

- The workpiece heating time is short, and the surface oxidation and decarburization is less.

- The workpiece surface hardness is high, the notch sensitivity is small, and the impact toughness, fatigue strength and wear resistance are greatly improved. It is beneficial to develop the potential of materials, save material consumption, and improve the workpiece service life.

- Compact equipment, easy to use, good working conditions.

- Easy to mechanize and automate.

- Not only for surface quenching but also for penetration heating and chemical heat treatment.

- Induction hardening equipment is generally an induction hardening machine tool, which consists of an induction heating power supply, a load line, a capacitor, a transformer, an inductor, and a machine tool.

Why use an induction hardening system?

After induction quenching, steel reaches the required hardness/toughness ratio through tempering, low-temperature induction heat treatment process. The maximum hardness of the steel grade obtained by the quenching treatment makes the material less ductile. By tempering steel, the hardness of the material is reduced and its toughness is increased. The hardening depth of the workpiece can be precisely controlled by adjusting the induction heating machine power output and the frequency of the induction coil current. The hardening of the steel surface improves the wear resistance of the part without reducing most of the ductility of the material. The high the frequency level, the less quenching depth, the lower the frequency level, the more quenching depth. Most of our induction quenching system frequency range is:

- Medium frequency:0.1-20KHZ

- High frequency:20-80KHZ.

- Ultrahigh frequency: 80-500KHZ.

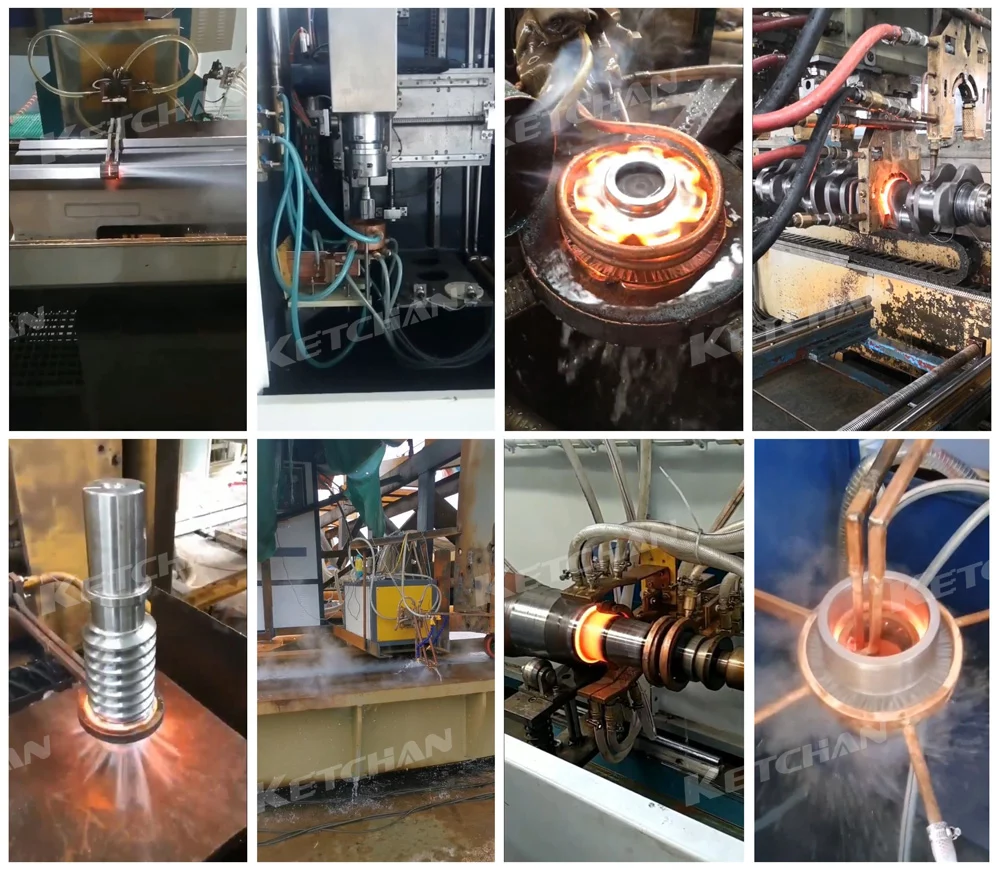

What is induction quenching system applications?

Our induction quenching systems are widely used in the different field metal induction heat treatment processes, and below I list some of our featured induction quenching systems.

- Full automatic crankshaft induction hardening system.

- Horizontal double stations CNC induction hardening machine.

- Turntable multi-stations induction hardening system.

- Car bumper induction hardening system.

- Water pump spindle, pin induction quenching system.

- Drive wheel, guide wheel induction quenching system.

- Ring gear, spiral umbrella, gear, tooth ring induction hardening system.

- Caliper frame, connector induction hardening system

- Bearing inner race induction hardening system.

- Camshaft, hub bearing induction hardening system.

- Other parts induction heat treatment process…

Why choose Zhengzhou KETCHAN?

Zhengzhou KETCHAN is a new high-tech company, that mainly supply induction quenching system including induction heating machine, CNC hardening machine tool, and industrial chillers. The machine frequency and power can be adjusted according to different application ranges. Also, we can customize different induction heating coils for different induction heating solutions.

We also have our own induction heat treatment lab, which can provide the related complex workpiece induction heat treating tests to help our users to find suitable induction quenching solutions.