What is ultra high frequency induction heater?

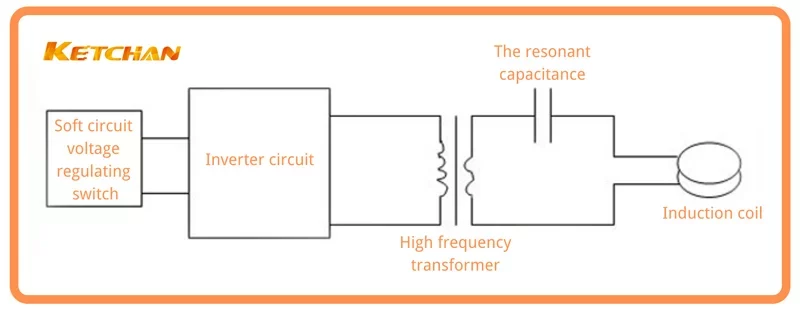

This series of ultra high frequency induction heater adopts series resonant circuit, after resonance through high-frequency transformer output low voltage, high current high-frequency power supply. Resonance structure is shown as follows:

This series of ultra high frequency induction heater equipment structure adopts ZHENGZHOU KETCHAN’s third-generation inverter control technology, on the basis of the use of conventional IGBT devices, so that the induction heater can not only output frequency up to 250 kHz ultra high frequency power supply, but also the ultra high frequency induction heater functions are more stable and high reliability. It makes the possibility to replace the vacuum tube high frequency with the solid-state high frequency induction heaters.

In this technology, the ultra high frequency induction heater power and frequency can be adjusted independently. IGBT switching device and amorphous inductor are used to form a high-frequency chopper circuit to adjust the power. Using IGBT series resonance and frequency automatic tracking technology to obtain precise soft switch control inverter process, so that the equipment under high power work reliability is greatly improved so that the equipment has been developed in the field of high power, 100% equipment temporary load rate can be achieved.

Schematic diagram of Ultra high frequency induction heater

What is ultra high frequency induction heater technical advantages?

ZHENGZHOU KETCHAN’s ultra high frequency induction heater resonant capacitor is connected in series with the high-frequency transformer side, so the high-frequency transformer has low voltage, which greatly reduces the insulation and ignition problems caused by high voltage, and greatly improves the reliability of the equipment. Meanwhile, the high-frequency transformer is small in size, light in weight, and low in loss.

Heating power, heating time, heat preservation power, and heat preservation time can be adjusted independently, which can effectively control the heating curve and heating temperature to a certain extent.

In the split ultra high frequency induction heater, the high frequency power supply (host) is separated from the high frequency transformer (extension), and the connection between the main and extension is 2 meters long;

When applied to the poor environment of the workplace, the induction heater’s main body can be closed in a clean space, greatly reduce the maintenance rate of the main body, increase the reliability of equipment;

When it is used in assembly line operations or complete sets of equipment, the small extension occupies a small table space, easy to move;

What are ultra high frequency induction heater applications?

During the metal heat treating productions, our ultrahigh frequency induction heaters have widely applications fields.

- Induction heat treatment of all kinds of different gear, shaft, and other parts.

- Carbon steel screws and stainless steel screws induction heating adhesive.

- Schools and research institutes use magnetic levitation smelting.

- Some copper pipes, tubes induction brazing jobs.

How to choose the suitable ultra high frequency induction heater model?

In the real induction heat treating production, ultrahigh frequency induction heaters are mainly used for the workpiece hardening depth less than 1.5mm conditions. We have the following induction heater models for your choice, these below induction machine models are standard ones, for different application cases, we can customize different ultrahigh frequency induction heater that meets your requests.

Model | Max. Input Power | Frequency | Memo |

KQC-10 | 10KW | 80-250KHZ | One Body |

KQC-20 | 20KW | 80-200KHZ | Split Body |

KQC-30 | 30KW | 80-180KHZ | |

KQC-40 | 40KW | ||

KQC-60 | 60KW | 80-150KHZ | |

KQC-70 | 70KW | ||

KQC-100 | 100KW | ||

KQC-120 | 120KW | 50-120KHZ | |

KQC-160 | 160KW | ||

KQC-200 | 200KW | ||

KQC-250 | 250KW | ||

KQC-300 | 300KW |

Our service

- After-sales service: all of our ultrahigh frequency induction heaters warranty period is 12 months, after this period, we will provide the machine whole life technical support, ensure the rich spare parts stock to supply to each of our users with basic costs.

- Machine installation: For small power induction heaters: installation is simple, connect cooling water and power supply is ok. For the induction heating systems: installation is complex, we provide the detailed drawings and provide the oversea service.