What is ultra high frequency induction heating equipment?

Ultra high frequency induction heating equipment is mostly used for the industrial metal parts surface quenching. It is a metal heat treatment method that produces a certain induction current on the workpiece surface, rapidly heats the surface of the part at high frequency, and then rapidly quenching. Super audio induction heating equipment, that is, induction heating the workpiece, to carry out the surface hardening equipment.

The principle of ultra high frequency induction heating equipment: the workpiece is placed into an induction coil, which is a generally a hollow copper pipe with the input of medium frequency or high frequency AC. Produce alternating magnetic field in the workpiece to produce the same frequency induction current, the distribution of the induction current in the workpiece is not uniform, strong on the surface, and in the interior is very weak, close to the core, using the skin effect, can make the workpiece surface heating rapidly, in a few seconds the surface temperature rises to 800-1000 degree, while the workpiece core temperature increases very little.

What is ultrahigh frequency induction heating equipment's technical advantages?

- Adopting Siemens IGBT power device unique inverter technology, 100% load duration design, 24 hours operation under maximum power, high-reliability guarantee.

- The automatic control type can adjust the heating time, heating power, heat preservation time, heat preservation power, and cooling time; Greatly improve the quality of heating products and heating repeatability, simplify the operation of workers.

- Lightweight, small size, simple installation, connected to 380V three-phase power supply, water inlet, and water outlet can be completed in a few minutes.

- Small volume, simple operation, a few minutes to learn.

- Especially safe, the output voltage is lower than 36V, avoiding the danger of high voltage electric shock.

- The ultra high frequency induction heating equipment efficiency is up to 90%, energy consumption is only 20%-30% of the high frequency of the old electronic tube, almost no electricity in the standby state, and can work continuously for 24 hours.

- The inductor can be quickly disassembled and replaced freely, and ultra-fast heating greatly reduces the oxidation deformation of the workpiece.

- The ultra high frequency induction heating equipment has over current, over-voltage, over temperature, water shortage, lack of such perfect automatic protection functions, and equipped with fault self-diagnosis alarm system.

- The equipment has the control function of constant current and constant power, which greatly optimizes the heating process of metal, realizes efficient and fast heating, and gives full play to the superior performance of products.

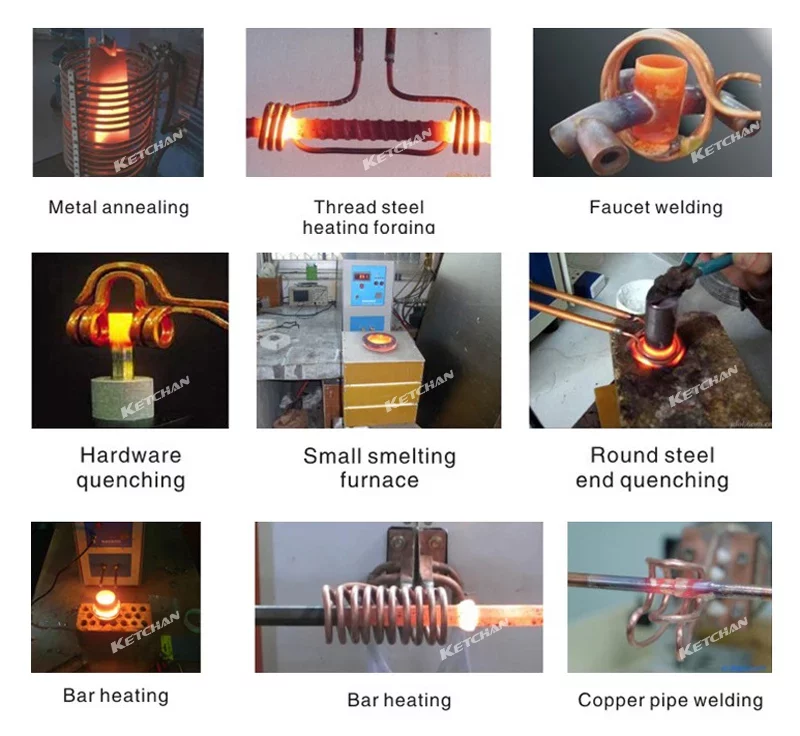

What are ultra high frequency induction heating equipment applications?

- Carbide saw blade size teeth welding.

- Welding annealing of spectacle frame and spare parts.

- Jewelry clock welding

- Electronic industry (extremely fine wire various electronic components fine parts tin welding silver welding).

- Mechanical and electrical industry (Fine metal joint silver brazing micro motor shaft quenching tempering).

- Wire Industry (Wire Strip annealing).

- Tool welding, paper cutting knife, shoe blade quenching.

- Toy Industry (Winding sheet metal tempering).

How to maintain ultra high frequency induction heating equipment?

- To prevent electric shock, ensure that the electrical specifications of the chassis are reliably grounded.

- Disassembly and installation of the inductor must be carried out after reheating is stopped.

- Strictly implement the principle of connecting water first and then powering on, water shortage is strictly prohibited in the working process, and the quality and pressure of cooling water used in the equipment and inductor must meet the requirements in Table 2. To avoid blocking the cooling pipes, if a water pump is used for water supply, install filter cooling water at the water pump inlet. The temperature should not be higher than 45°C, and the water flow should be 10T/H (softened water is recommended).

- The ultra high frequency induction heating equipment must be protected from sunlight, rain, humidity, and dust. When the device needs to be repaired or maintained, it must be repaired after the power is off.

- Clean the machine with compressed air or a fan every week. The circuit board is cleaned with a brush and then blown clean.

- Ordinary users should be used it every 4 months with special detergent (our company available) to clean the machine once. When the machine frequently alarms water temperature, or observe the water flow at the outlet significantly reduced should be cleaned immediately.

- The inductor should be kept clean to prevent a short circuit between turns.

- This ultrahigh frequency induction heating equipment cannot use a single turn sensor. Otherwise, the device may be damaged due to too small inductive reactance. In special cases, please consult the manufacturer.

- When replacing the inductor, the inductor connecting plate and the transformer contact surface should be sanded clean to maintain good conductivity.