Why do the valve induction hardening?

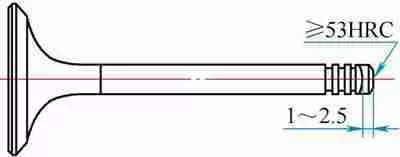

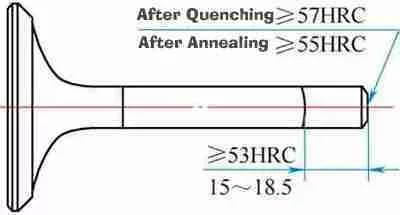

In order to improve the service life of the engine valve, we should do the valve stem and cone surface induction hardening process. The quenching hardness is usually 50-62 HRC, induction quenching length or depth ≥ 2 mm, the fine grain size in magnitude 8, etc., According to the valve service conditions and requirements, the valve rod end quenching can be divided into the valve stem full hardening, rod end impact quenching, stem profile quenching, etc. These years after serving some famous valve manufacturers, we are updating our valve induction hardening machines always to make them faster, stable, and commercial.

How to do the valve induction hardening machine coil?

Valve rod end quenching is achieved by high-frequency induction hardening equipment and inductor. The induction heat treatment quality and the equipment efficiency and utilization depend largely on the inductor structure design and manufacturing. According to the type and characteristics of valve rod end quenching inductor, it can be divided into the plane inductor, U-shaped or rectangular inductor (copying), open continuous quenching inductor (rod end quenching, etc.), meet its different end face hardness, quenching length or depth technical requirements, etc. In the valve rod end quenching process, the basic requirements for quenching inductor are as follows:

- The inductor is welded with a rectangular (or round copper tube) pure copper tube or copper plate to avoid the sharp corner effect at right angles and prevent overheating or burning at the corners.

- The inductor should be equipped with a magnetic guide to improve heating efficiency during impact and profile quenching.

- Easy to install, make and adjust, with enough strength, not easy to deform in the heating process, and convenient to clean the scale and external dirt in the inductor.

- For continuous quenching through type inductor, the upper and lower, the inside of the insulation tiles, to prevent ignition, to prolong the service life, and have better cooling conditions.

A large number of production practices have proved that the use of a rectangular inductor instead of a cylindrical inductor has obvious advantages in improving the quality of induction quenching at the valve rod end, prolonging valve service life, and increasing productivity, shortening auxiliary time and simplifying quenching equipment.

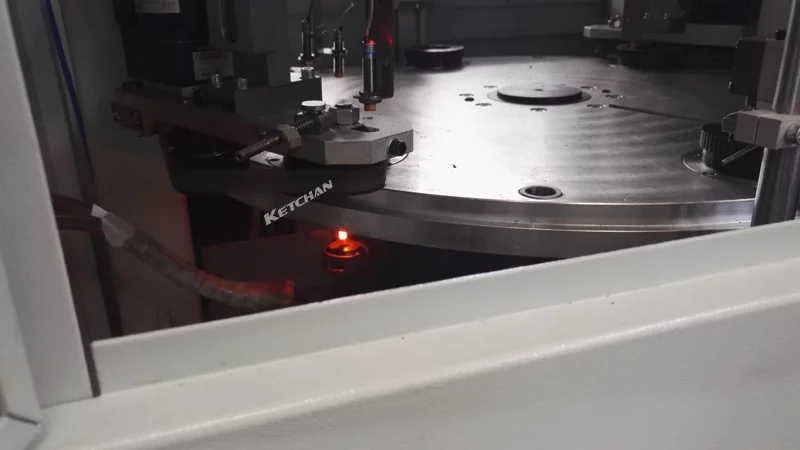

What is valve induction hardening machine technical features?

The main features of our automatic valve induction hardening machine are as follows:

- The inductor is fixed, and the quenching length of the valve rod is stable.

- Adopting quenching energy to adjust the heating temperature, has good control performance.

- Automatic loading and unloading, artificial intelligent control, and high and low temperature alarm separation.

How to do the valve induction hardening ?

In order to ensure that the quality of the valve rod end after quenching meets the technical requirements, the induction hardening coil and the structure of the cooling system should be selected according to the valve rod end hardening technical requirements. According to the results of the process test to determine the best process parameters, and according to the specific requirements do the following specific process control.

- To determine the valve induction hardening machine heating power, voltage, current (heating temperature) or heating energy, heating time (beat) or feed speed, and so on.

- Quenching cooling medium temperature, spray pressure, oil or water quenching cooling medium concentration range and cooling time.

- The quenching cooling medium circulation system should be cleaned regularly. After each shutdown or restart of the faulty equipment, the rod end quenching should be carried out after the quenching cooling medium is circulated for 20 minutes.

- The magnetic conductor should be connected to the inductor reliably and ensure that it is parallel to the inner wall of the inductor.

- The structural size of the inductor and cooling system should be consistent with the valve rod quenching requirements.

- Engine valve rod end quenching positioning device and clamping or pressing device should be inspected every shift, and abnormality should be stopped for inspection.

What is KETCHAN valve induction hardening machine data sheet?

Process range | Valve diameter:5-10mm, valve hat diameter 20-50mm, total length 70-150mm. |

Material | 21-4N, 4Cr10Si2Mo, original hardness 25-45HRC |

Hardening depth | 2-5mm |

Hardening hardness | More than 50HRC |

High frequency induction heating machine | Voltage: 380V~480V 50hz/60Hz Frequency:20-60KHZ |

Total power | 40KW |

Production speed | 5S/Piece |