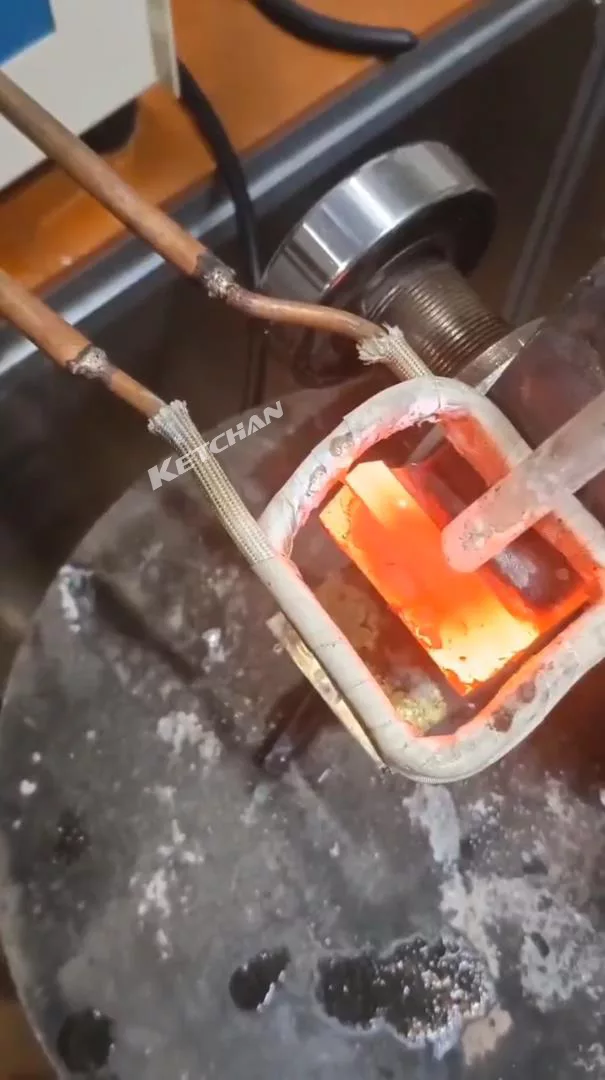

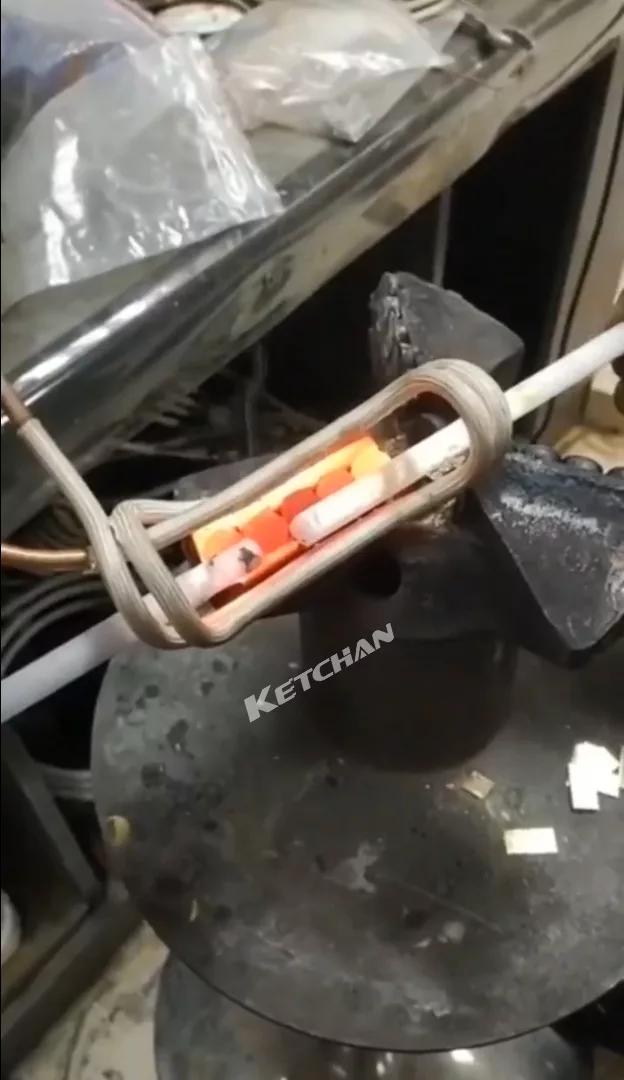

Alloy induction brazing is a process of joining two or more metals or non-metals that may be the same or different by using a filler metal or alloy with a lower melting point than the base materials. It involves placing the parts to be joined inside or near an induction coil, which generates a high-frequency alternating magnetic field. The magnetic field induces eddy currents in the parts and the filler metal, which heats them up to their melting or brazing temperature by the Joule effect. The filler metal then flows into the gap between the parts, forming a strong and durable bond upon cooling. Alloy induction brazing can be used for various applications, such as joining steel assemblies, copper tubes, carbide tools, valves, busbars, etc. It can also be used for joining dissimilar metals and alloys, such as nickel, copper, cobalt, titanium, and steel. Some non-metals, such as ceramics, graphite, and glass can also be brazed using induction.

Some of the advantages of alloy induction brazing are:

- Induction brazing is fast and precise, as it can heat only the desired part of the metal or the crucible, avoiding unnecessary heat losses and improving temperature control.

- Induction brazing is clean and safe, as it does not produce any flame, smoke, or harmful emissions. It also reduces oxidation and scaling on the parts.

- Induction brazing is energy-efficient and cost-effective, as it does not require any contact or moving parts. It can also be easily integrated into automated production lines.

- Induction brazing produces high-quality joints that are leak-proof, strong, and reliable. It can join dissimilar metals and alloys without melting them or affecting their metallurgical properties.

Some applications of alloy induction brazing