What’s Induction Hardening?

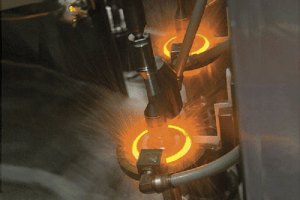

Induction hardening is a quenching method that uses the principle of electromagnetic induction to make the workpiece cut magnetic field lines in the alternating magnetic field and generate induced current on the metal parts’ surface. According to the skin effect of alternating current, the surface of the heated part is rapidly heated in the form of an eddy current and then induction quenching quickly.

After the induction heating machine finishes the heating and quenching process, the metal parts’ surface hardness is high, and the core maintains good plasticity and toughness, showing low notch sensitivity, so the impact toughness, fatigue strength, and wear resistance are greatly improved. Due to the short heating time, the surface oxidation, and decarburization of parts less, compared with other heat treatments, the parts rejection rate is very low. Also choosing the suitable induction heating coil plays an important role in the field of metal induction heat treatment. Operation is easy to realize mechanization and automation, high productivity.

Why Use Induction Hardening Process?

Induction hardening is a process in which eddy currents are generated in the metal workpiece by electromagnetic induction and the workpiece is heated. Compared with common metal heating technology, induction hardening technology has the following advantages:

- The metal workpiece surface hardness is high. The surface hardness of workpiece hardened by high and medium frequency induction heating is 2 ~ 3 HRC higher than that of ordinary quenching. Its metal impact toughness, fatigue strength, and wear resistance are greatly improved. The service life of a metal workpiece can be greatly extended by induction quenching.

- The metal workpiece is not integral heating, so with induction hardening, the workpiece’s overall deformation is small.

- Metal workpiece heating time is short, and the surface oxidation decarburization amount is less.

- The heating source works on the metal workpiece surface, and heating speed and efficiency are high.

- Induction hardening equipment structure is more compact than common metal induction heating equipment and easy to operate.

- Induction hardening machines realize mechanized and automatic heat treatment processing, saving labor costs.

- Induction hardening technology in surface hardening can also be used in penetration heating and chemical heat treatment.

What are the Components of The Induction Hardening System?

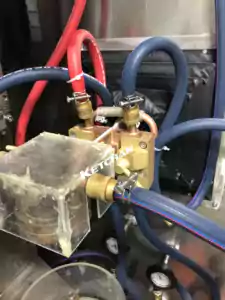

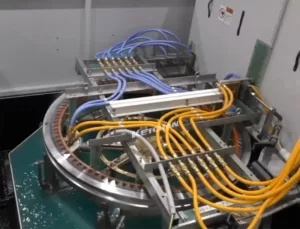

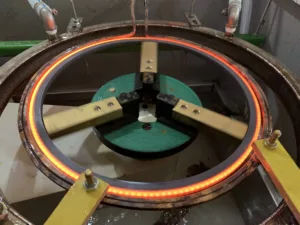

The composition of a complete induction hardening equipment generally includes an induction heating power supply, CNC induction hardening machine tool, induction hardening coil, and the auxiliary cooling water circulation system and quenching liquid circulation system.

Modern induction heating equipment manufacturers, a considerable part of the ability to undertake complete sets of induction hardening equipment and turnkey project, the user from order to shorten the production cycle, and avoided due to multiple supply departments in the process of debugging is not harmonious, and the long debug ills such as time. The supply of complete equipment and turnkey projects has become a means of competition for equipment manufacturers.

In total, As one of the leading induction hardening system manufacturers in China, we have helped thousands of heat treatment factories to find suitable induction hardening heat treatment solutions already, so in order to make sure the suitable induction hardening system induction quenching process. You can please let us have your hardening parts drawings, material, hardness, hardening depth requests, and we can give you the related induction heating hardening system technical suggestions along with the quotation sheets. Thanks.

How to Choose the Appropriate Induction Hardening Process?

The induction hardening process has several heating methods and all have suitable heating workpieces.

- One-time induction heating hardening method:

One-time induction heating or simultaneous induction heating is the most common induction hardening method. When this method uses two rectangular tubes surrounding the workpiece surface for rotary heating, it is conventionally called a Single Shot.

The advantage of this induction heating method is to complete all the workpiece surface area induction heating jobs at a time. Therefore, its operation is simple, productivity is high, and it is suitable for heating the workpiece area is not too large. For heating the particularly large area workpiece, adopt the one-time heating method, it requires considerable power and high investment cost.

The most common examples of one-time induction heating hardening are small and medium modulus gears, CVJ bell-shaped shell bars, inner raceways, carrier wheels, support wheels, leaf spring pins, pullers, valve ends, and valve rocker arm arcs, etc. - Scanning induction hardening method:

When the workpiece heating area is large, and the induction heating power supply is small, this method is often used. At this point, the calculated heating area S refers to the region contained by the induction ring. Therefore, with the same power density, the induction heating machine required power is small, the competitive induction hardening equipment investment cost is low, suitable for small batch induction hardening production, typical examples are large-diameter piston rod, corrugated roll, roll, oil pipeline, sucker rod, rail, machine tool guide rail and so on. - Subsection one-time induction heating quenching method:

Typical examples are the multiple camshafts induction hardening, each time heat one or more cams, after finish this time induction quenching, heating another cam part, the gears are hardened tooth by tooth can also be included in this category. - Subsection induction scanning hardening method:

Typical examples are valve rocker shafts or variable speed shafts induction hardening, where multiple parts of a shaft are scanned for induction quenching, the quenching widths may be different, and tooth by tooth scanning quenching may also be included in this category. - Induction heating and hardening in liquid:

Induction hardening in the liquid, means the induction coil and the workpiece heating surface are immersed in the induction hardening liquid, heated, due to the heating surface power density being greater than the surrounding quench fluid cooling rate. Therefore, the surface heats up quickly. When the inductor is powered off, the surface of the workpiece is hardened due to the heat absorption of the workpiece core and the cooling of the hardening fluid.

This method is generally suitable for steel workpiece which requires a less critical cooling rate. When the workpiece is placed in the air and the induction coil is powered off, the heat of the surface is absorbed by the center of the workpiece. When the cooling rate of the heated surface is greater than the critical cooling rate, the workpiece is hardened, which is similar to the quenching in the liquid.

Tags:Automatic Induction Heat Treating, Ball Stud hardening, Ball Stud heat treating, Ball Stud quenching, Ball Stud temepring, camshaft hardening, camshaft induction hardening, CNC hardening, CNC Quenching, CNC Quenching Machine, CNC Quenching Machine Tool, crankshaft hardening, crankshaft hardening machine, Disc CNC Hardening, for Sale, gear hardening, gear hardening heat treatment machine, gear induction hardening, Gear Induction Heating Machine, Gear Quenching Machine, Gear Teeth Quenching, heat treatment machine, High Frequency Induction Hardening, High Frequency Induction Quenching, Horizontal Hardening Machine Tool, induction ha, induction hardening, induction hardening auto valve, induction hardening machine, induction hardening tempering, induction heater, induction heating, induction heating machine, induction quenching, induction quenching machine, Induction Quenching System, Induction Scanner, Induction Scanning, induction shaft hardening, KETCHAN, KETCHAN Electronic, Manufacturers, price, rdening scanner, rod hardening, Shaft CNC Hardening Machine, shaft hardening, shaft heat treatment, shaft induction hardening, shaft induction hardening machine, shaft induction heating, shaft quenching machine, Suppliers, ultra high frequency quenching, vertical induction hardening machine, Zhengzhou KETCHAN, Zhengzhou KETCHAN Electronic

- You can visit Zhengzhou KETCHAN electronic Co.,ltd Youtube video room for more. Thanks.