What’s Induction Heating?

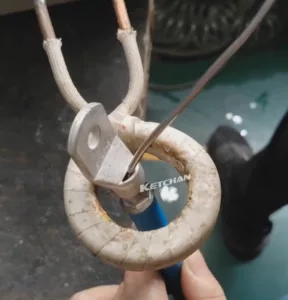

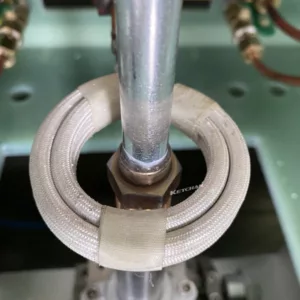

Electromagnetic induction heating, or called induction heating, is a method of heating conductive materials such as metals. It is mainly used for metal hot induction forging, induction heat treatment, induction welding, and induction melting. As the name implies, induction heating is using the electromagnetic induction method to heat the material to generate electricity inside, relying on the energy of these eddy currents to achieve the induction heating purpose. The basic composition of an induction heating system includes an induction coil, AC induction heating power supply, and workpiece. The coils can be made into different shapes depending on what is being heated. The coil is connected to an induction heating power supply, which provides alternating current to the coil. The alternating current flowing through the coil creates an alternating magnetic field through the workpiece, which generates eddy currents to heat the workpiece.

What Are Zhengzhou KETCHAN Featured Induction Heating System?

Zhengzhou KETCHAN induction heating system is widely applied to a range of industrial applications, advanced product technology, perfect pre-market after-sales service, and many application experiences, make our customers in different areas through cooperation with us, meet high efficiency and reliability production operation needs. Thus, we have gained a good reputation in the application process in different areas of the world.

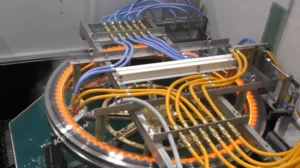

- Induction heating treating: After a long time serving in the induction heat treatment fields, we have done many different induction heating systems used in different workpiece induction heating. We have the rich practical experience and a large number of practical cases that can solve all kinds of heat treatment problems for you, As per request, can match energy monitoring systems,special-making robot induction heating systems, in-time records, save and query key production parameters. For example, voltage, current, power, hardening medium flow, hardening medium temperature, etc., can export historical data for easy query. And to achieve intelligent automation workshop, MES order management. The induction heat treating system is mainly used in the gears, sprocket gears, belt pulley, ball pin, spline shaft, gear shaft, crankshaft, camshaft, saw blades, hub bearing, TVJ, CVJ, ring gears, bell shells, universal joint, ball screw, transmission shaft, sleeves, slewing bearing, gear ring, caterpillar track section, etc induction hardening quenching process.

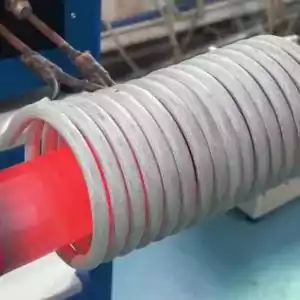

- All kinds of different wires, steel strips, and plate induction heating treatment equipment systems. Mainly used for the workpiece with a diameter of 0.5-20mm and with thickness above 0.5mm. For the induction heating blueing, induction hardening, induction tempering, induction annealing, induction coating, and induction classify process.

- All kinds of different billets, rods, bars induction forging, stainless steel solution Induction Forginginduction treatment, pipes and tubes induction heating, induction heating forging, pipe induction heating hot bending systems. One machine can match work with multi different induction heating furnaces and steel billets, full automatic induction heating system matching working.

- All kinds of oil petroleum pipeline induction heating, oil coil pipe induction heating, and large pipe preheat before welding and heat treatment after welding. Based on these applications, Zhengzhou KETCHAN developed an air-cooled induction heating machine to finish all different complex working environments, this induction heating machine does not need water cooling, fast heating speed, and is easy to operate. According to different induction, heating parts can custom different induction coils.

- All kinds of different material induction melting processes. Like steel, alloy steel, cast iron, stainless steel, copper, aluminum, zinc, etc. We have smaller induction melting furnace with a crucible. Bigger steel shell induction melting system, and aluminum shell induction melting system to meet all of your meeting requests.

- All kinds of copper tubes, aluminum tubes, pipes, joints, HVAC Parts, AC distributors, heat exchanger tubes, motor rotors, compressors, and stainless steel induction brazing welding process. Mainly with our handheld induction heating machine and also small power portable induction heating machine with 5m cables.

- All kinds of bearings, motors induction shrink fittings.

- We have thousands of induction heating systems application cases after serving thousands of different induction heat-treating factories. So for more complex induction heating systems working videos, you can visit Zhengzhou KETCHAN electronic Co.,ltd Youtube video room for more. Thanks.

How can I get a induction heating system quotation?

We have been in the induction heating fields since 2000, serving thousand of heat treatment factories, and doing all kinds of different workpiece applications. You can please let me know your heating, brazing, hardening, forging, melting parts details, and drawings with technical requests will be appreciated. So that we can give you some more technical suggestions along with quotations. We are expecting business cooperation with you in the future. Hope our machines have a chance to serve in your factories. Thanks.

Tags:induction annealing, induction brazing, induction forging, induction hardening, induction hardening tempering, induction heat treating, induction heat treatment, induction heater, induction heating, induction heating equipment, induction heating machine, induction heating process, induction heating system, induction melting, induction preheating, induction quenching, induction tempering, induction welding, KETCHAN, KETCHAN Electronic, Manufacturers, price, Suppliers, Zhengzhou KETCHAN, Zhengzhou KETCHAN Electronic