What’s Induction Brazing?

Induction brazing is using alternating magnetic field – electromagnetic induction phenomenon, the eddy current effect in the magnetic field heats the workpiece, melting the solder flux, a method for induction brazing by filling the gap with liquid filler metal under the action of the capillary. Compared with other brazing methods, the induction brazing welding machine has the unique characteristics: fast heating speed, ease to achieve local heating, can realize the heat concentration, ease to control temperature, ease to achieve automation operation, these peed, agility, and low-cost characteristics make induction brazing welding machine more suitable for the current social market requirements.

What Is Induction Brazing Welding?

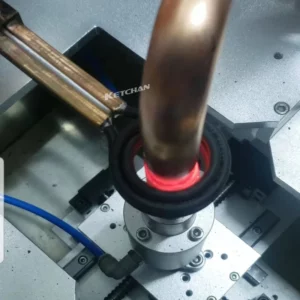

When doing the induction brazing welding, the brazing part is placed in an alternating magnetic field, and the heating of the denominator is achieved by the resistive heat of the induced current it generates in an alternating magnetic field. The strength of the induced current in a conductor is proportional to the frequency of the alternating current, as the alternating current frequency increases, the induced current increases, and the welding part is heated faster. For this reason, induction heating mostly uses high-frequency alternating current. In addition, the skin effect is also related to the electrical coefficient and permeability of the material. The greater the resistivity, the smaller the permeability, the weaker the skin effect, and the more significant the skin effect.

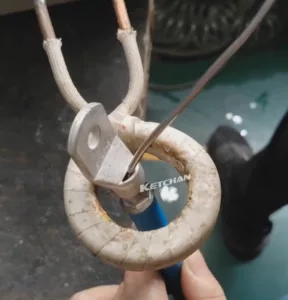

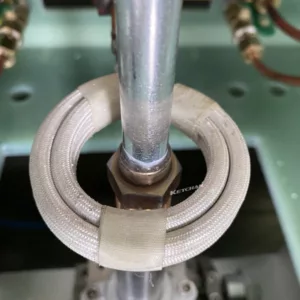

Also, the induction brazing welding coil is an important part of the induction brazing machines.

For the general induction brazing work, an induction heating frequency of about 500KHZ is more suitable.

What Are Induction Brazing Machines Advantage?

Because induction brazing is different from laser brazing, its effect is not affected by the brazing position or joint changes.

The induction brazing welding system provides faster and more uniform heating than soldering iron. The soldering iron head will wear out and need to be replaced frequently, while the induction brazing welding coil is almost wear-free because it is contactless. Compare to gas flame brazing, induction heating brazing welding has many advantages, can conduct more heat per unit area of material, and the brazing temperature is usually reached in a few seconds, this results in a faster heating cycle and higher hourly output production.

The induction brazing welding system can be performed selectively, allowing the user to operate with small amounts of assembly or partial workpiece induction brazing welding. Induction brazing has advantages over other brazing methods when it is necessary to confine the heat to a specific area of the workpiece for local heating. Due to the high degree of heat localization, solder joints quickly reach the required melting temperature without risking damage to the workpiece.

As a result, induction brazing is more economical and is ideal for automated, mass production processes due to its high repeatability.

What Industries Can Use Induction Brazing System?

In recent years, induction brazing equipment solutions are used in many industries around the world, but in general, most brazing application scenarios can be divided into the following:

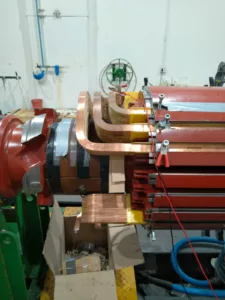

- Electricity electrician fields: In this field application, our induction brazing machines are mainly used in the generator, transformer, turbine engine, switchgear, automobile, short circuit ring, etc. induction brazing welding jobs.

- Auto industries induction brazing solutions: Most induction brazing machine solutions are used in the mass production of automotive fuel lines and air conditioners. We have extensive experience in designing brazing solutions. Such as aluminum components for air conditioning systems, connecting parts for evaporator and condenser, brake lining and fuel injection pipe induction welding and the electric motor short circuit ring induction welding system, etc.

- Household appliance industries: White appliances and HVAC have been important user groups for induction brazing solutions for many years. Zhengzhou Ketchan provides the most economical induction brazing equipment and technology to the world’s leading manufacturers of refrigerators, freezers, dishwashers, and washing machines as well as plumbing and household equipment industries. Mainly used for compressor components and some other heating elements tube to tube, tube and tube to valve connection induction brazing welding, and involves copper to copper, copper to aluminum, and aluminum to aluminum induction brazing.

- Tools industries: Induction brazing equipment is often used mainly to braze carbide tips and blades to saws, handles, etc. Because only induction brazing has the same precision and control required to manufacture such tools.

- Other special industries: our induction brazing system is widely used in many different industries and different parts of induction brazing welding projects. Like cables, aviation, furniture, plumbing, shipbuilding, railways, agriculture fields induction brazing welding, and so on.

How to choose the right induction brazing equipment?

In practical working, we need users to provide us with detailed induction brazing parts drawings, pictures, technical requirements, and work efficiency requirements, submitted to our technical team to get the most economical and efficient induction brazing solutions. Our induction brazing equipment can be automatic, semi-automatic, or manual in three modes of operation.

Our automatic induction brazing welding system includes the following parts:

- Automatic loading and unloading

- Automatic flux and brazing process

- Automatic temperature control

- Automatic coil positioning device

- Customized induction brazing coil design

- Complete system diagnostics

- Touch screen, main menu, and multilingual control surface.

- Advanced PLC control system

- Industrial chiller

- All of our induction brazing welding machines adopt the Ketchan induction brazing process. Also can be divided into fixed induction brazing machines and portable induction brazing machines (handheld induction brazing machines) etc.

Why choose Ketchan Induction Brazing System?

In the recent market, there are many different induction brazing system manufacturers including fixed induction brazing machines, handheld induction brazing machines, and portable induction brazing machines. And why do we suggest choosing Zhengzhou Ketchan portable induction heaters, handheld induction heaters, and fixed induction heaters for brazing welding jobs? The reasons are as follows:

- Fast induction brazing speed: Compare to other induction brazing machines. Ketchan induction brazing machines are faster heating speed, high heating precision, and less damage to the brazing parts around the environment.

- More flexible: Ketchan Induction brazing is an ideal field welding method, batch workpiece does not need to separate induction welding, and also does not need to leave the site that can be directly welded. Also, the portable induction brazing machine and the handheld induction heaters have a smaller volume, are very easy to install, and layout to arrange operation.

- Uniform brazed parts: When doing the induction heating jobs, Ketchan Induction heating machines have good controllability and repeatability, input the required process parameters, and induction heating equipment will repeat the heating cycle to confirm the uniform induction brazing result.

- Can be controlled the braze welding process: The operator can see the whole induction brazing welding process clearly to ensure the operation process is smart.

- Good working environment: With the Ketchan induction brazing welding system, the working environment is silent and clean, air purification device ensures the safety and health of operators.

- No contact induction heating brazing: The heat generated by the Ketchan induction heating brazing machine is in the solder area, and the metal outside the solder joint does not need to contact the heat source. The temperature is evenly controlled, the deformation is very small, and there is no potential safety hazard.

We have many different induction brazing welding systems for different users in different fields including HAVC, HVACR, etc. And have served thousands of industries on induction brazing projects. So we would be glad to provide you with the most commercial and suitable induction brazing solutions with our rich experience.

Now please do not hesitate to write letters to us to tell us your brazing parts details, you will get the most professional induction brazing ideas for your future better development. Thanks.

Tags:for Sale, high frequency brazing machine, induction brazing AC hoses, induction brazing AC pipes, induction brazing AC system, induction brazing AC tubes, induction brazing Air conditioning piping fittings, induction brazing aluminum, induction brazing aluminum distributors, induction brazing aluminum fittings, induction brazing aluminum heat exchanger, induction brazing aluminum pipes, induction brazing automobile AC pipes, induction brazing automobile AC tubes, induction brazing compressor pipes, induction brazing condenser pipes, induction brazing copper, induction brazing evaporator pipes, induction brazing HVAC pipes, induction brazing machine, induction brazing muffler parts, induction brazing pipes and fittings, induction brazing pressure tubes, induction brazing radiator tubes, induction brazing receiver drier parts, induction brazing automobile AC fittings, induction heater, induction heating, induction heating machine, induction soldering, induction welding, induction brazing, KETCHAN, KETCHAN Electronic, Manufacturers, price, Suppliers, Zhengzhou KETCHAN, Zhengzhou KETCHAN Electronic

- You can visit Zhengzhou KETCHAN electronic Co.,ltd Youtube video room for more. Thanks.